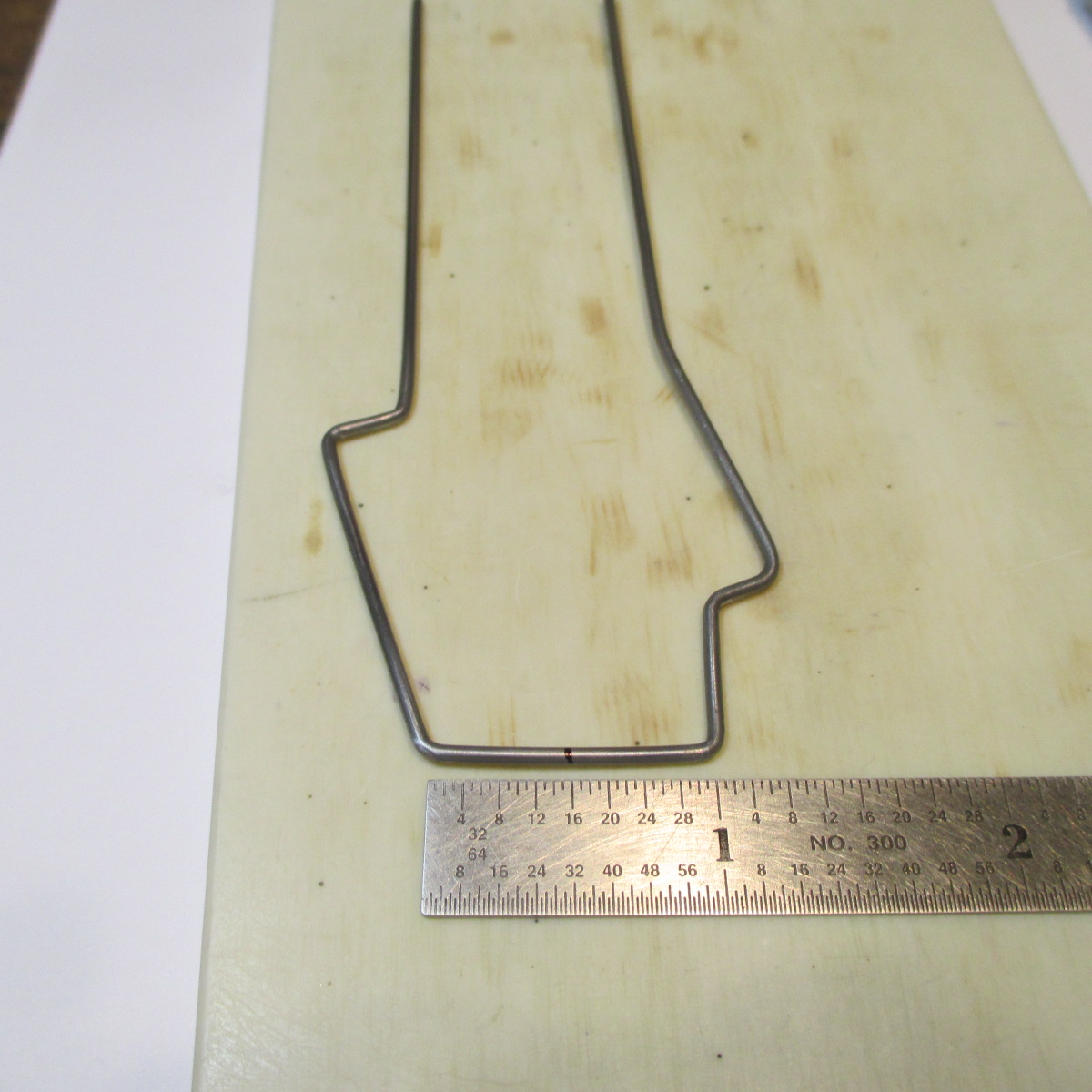

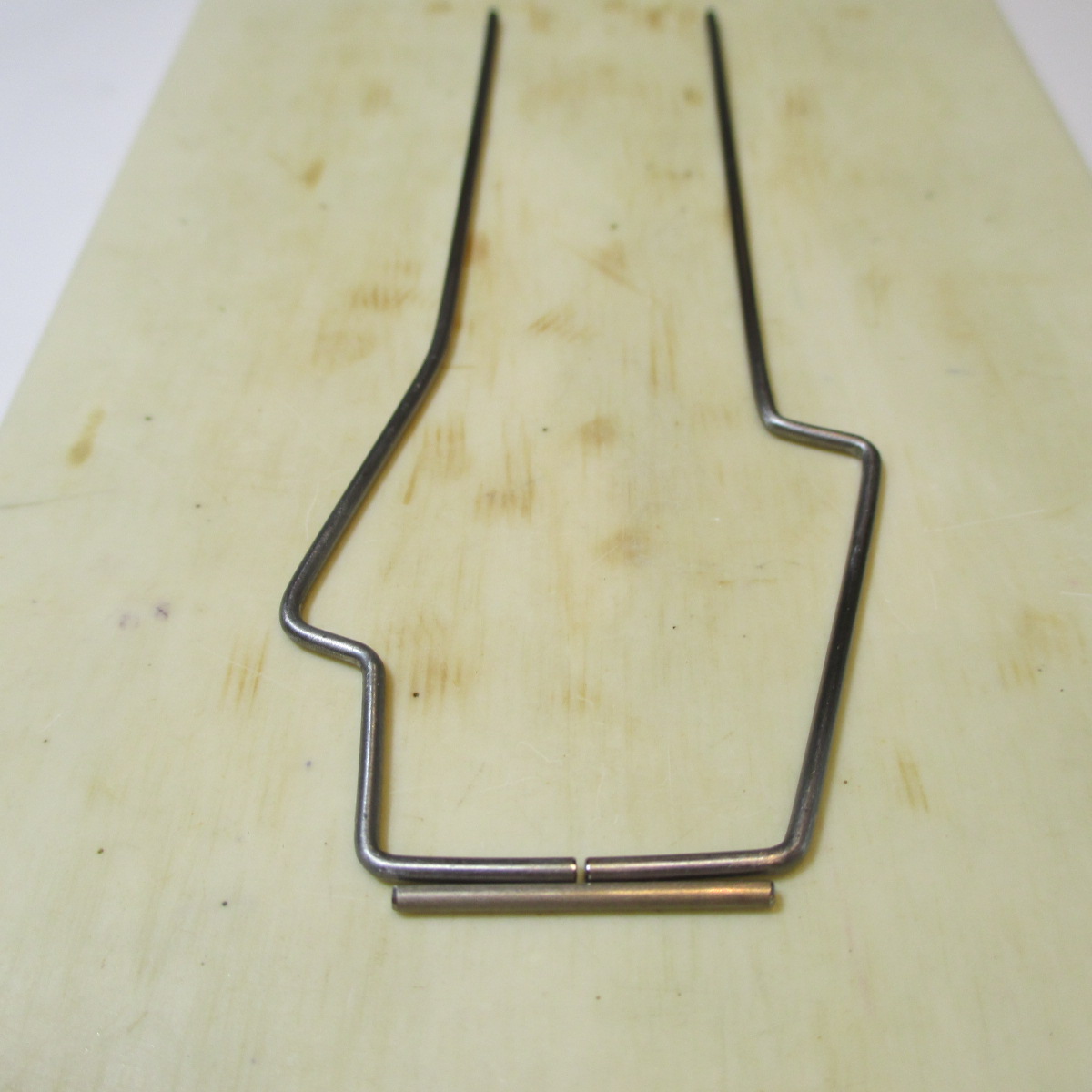

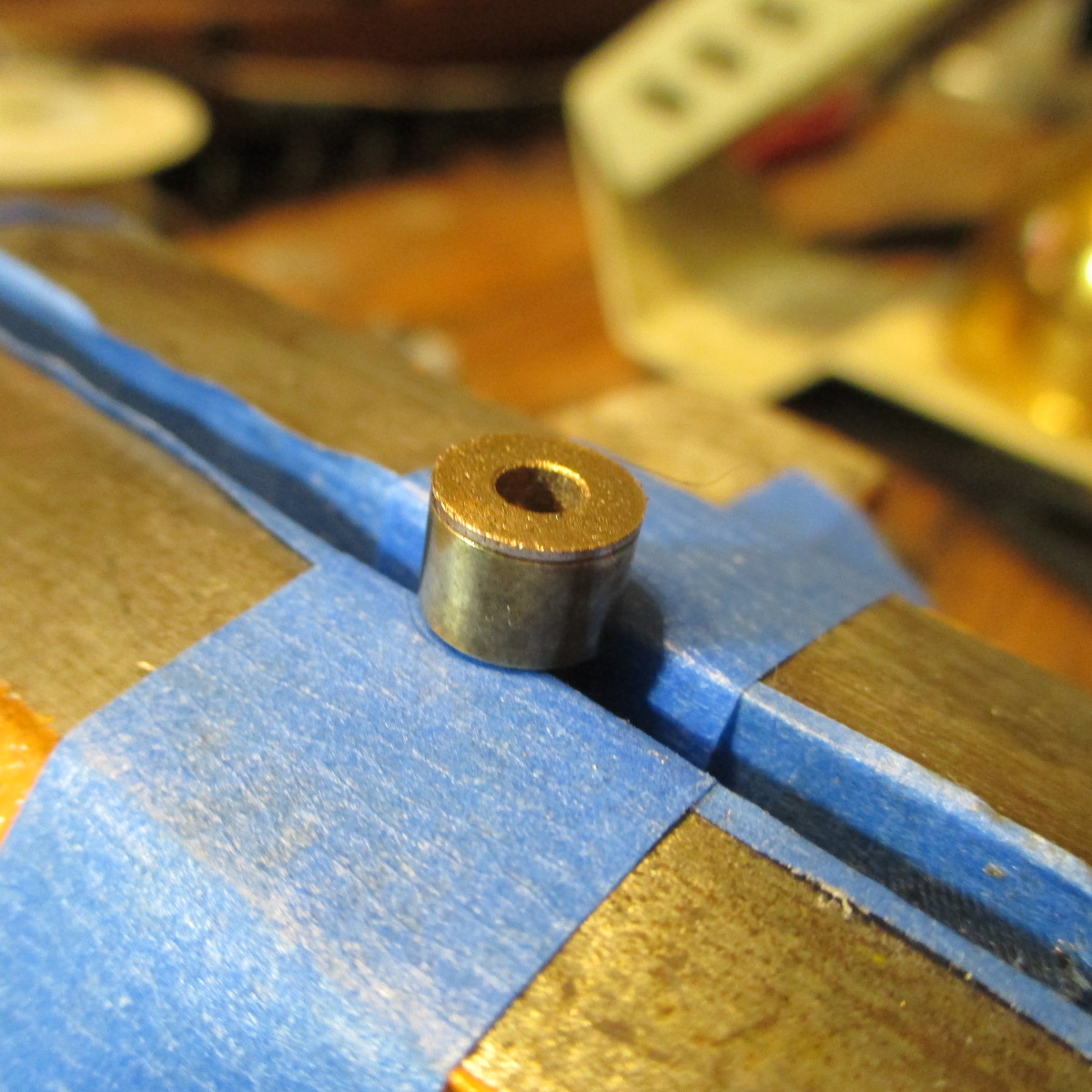

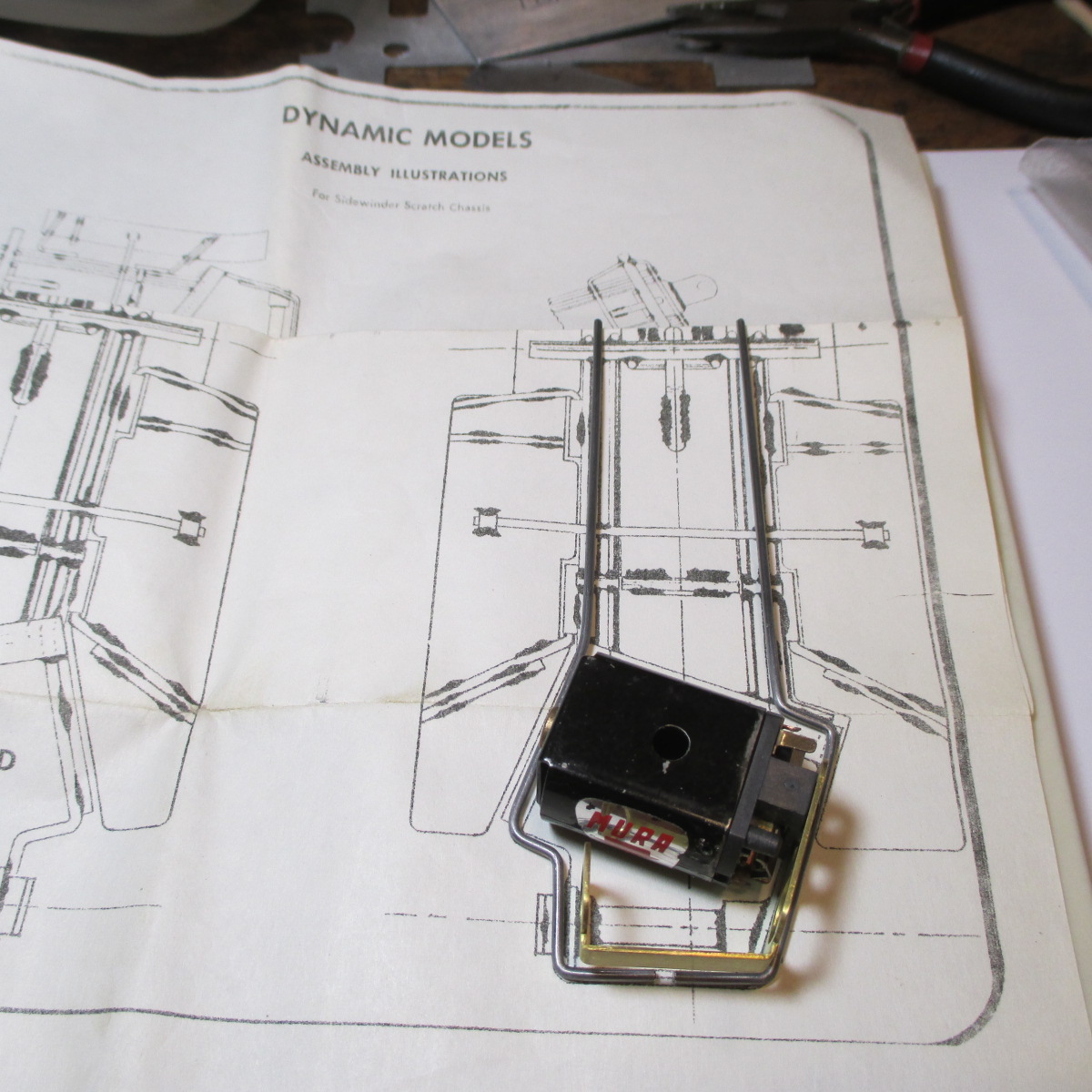

New in bag and original box, looks like Dynamic had a hard time deciding what to name it:

-"Sidewinder Chassis Kit"

-"Scratch Sidewinder Chassis Kit"

-"Bat Pan Sidewinder"

-"Sidewinder Scratch Chassis"

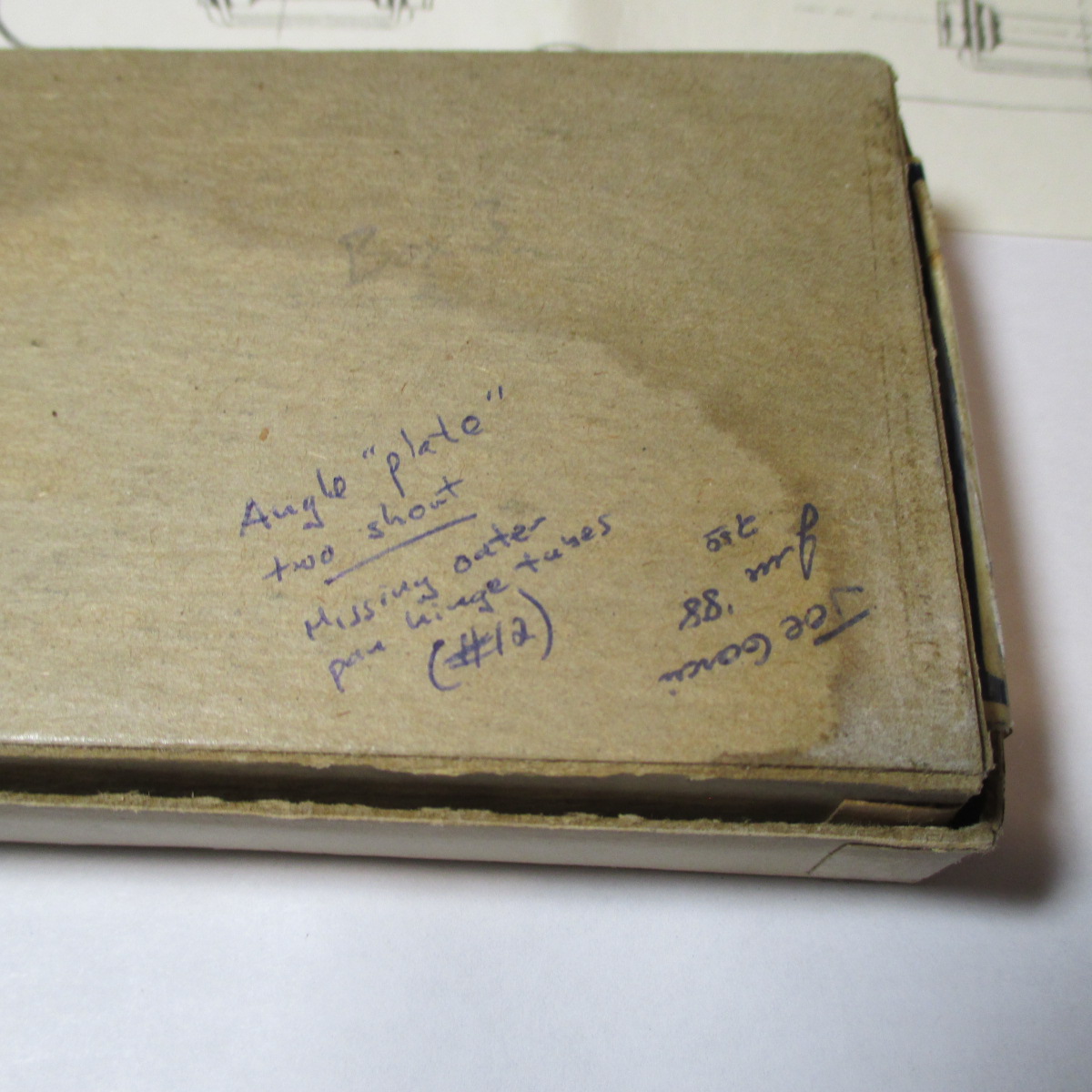

And it's not even a sidewinder LOL Plus there are multiple ways shown how to make it, including left hand or right hand drive. I chose to call mine "Dynamic Batwinder". No matter what you call it, it's an ultra cool kit. Top of the box is marked "$4.95" in pencil and bottom has some notes hand written in ballpoint pen