Hi All,

Has been some time since my last post and I'm finishing the design with some assistance that has helped greatly in the planning.

I have been recovering from a stupid motorcycle tip over in the grass up a slight hill on the first ride of the season and it landed on my LH foot/ankle six weeks thus far. Nothing broken or fractured just squished and bruised.

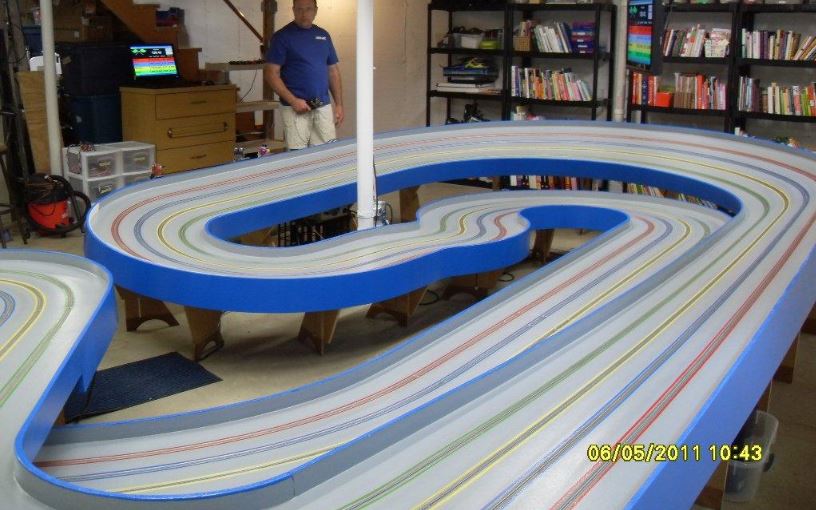

The track layout is stable with some refinements. I have added two banked turns with a few minor turn banks to keep the car on the track on the loop and elsewhere.

The large LH sweeper (Sections 12-13) is a 20 degree bank, 12 degree in Section 2 and flat on Section 4 (S4 and S7) with S8 and S9 a minor bank. Refining the fabrication methods for this track.

I wanted to see what the track would look like so I created the 3D model for fun. The banking in the two large turns was not calculated properly so the banks are a bit wavy but I got the feel for it.

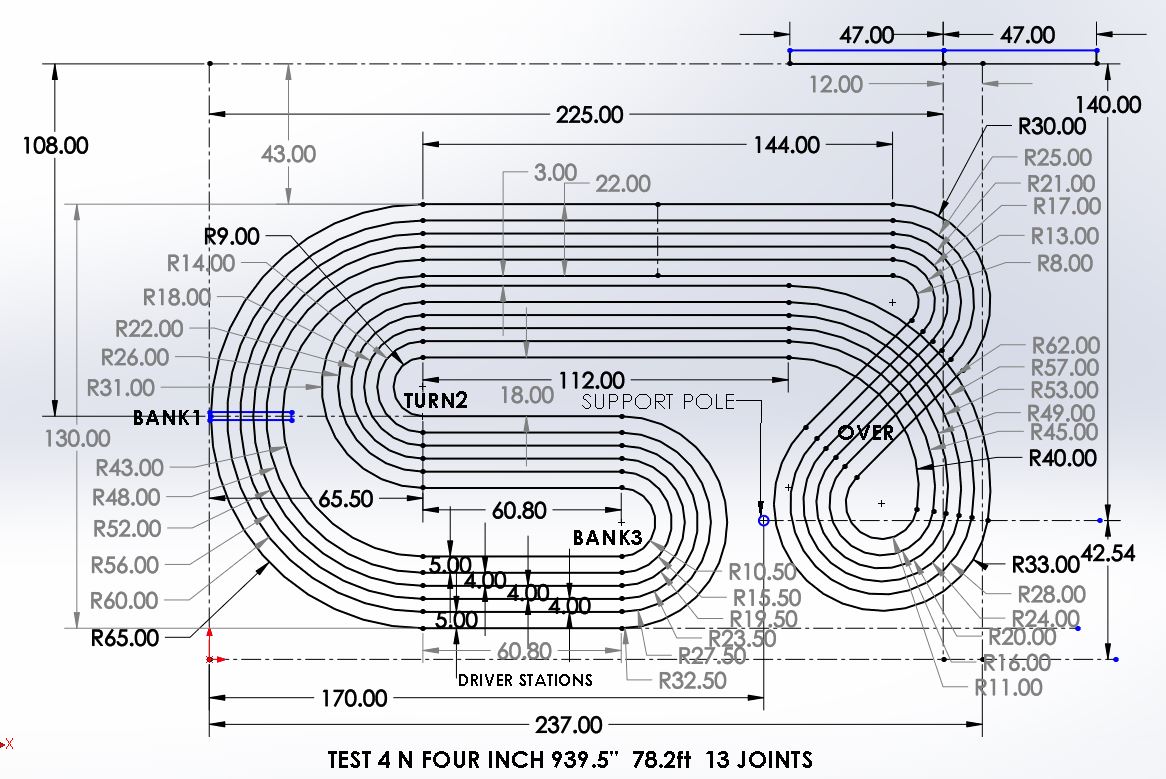

A warning about the 2D track layout seen below....it has dimensional information on it but it is for a flat track without any banking.

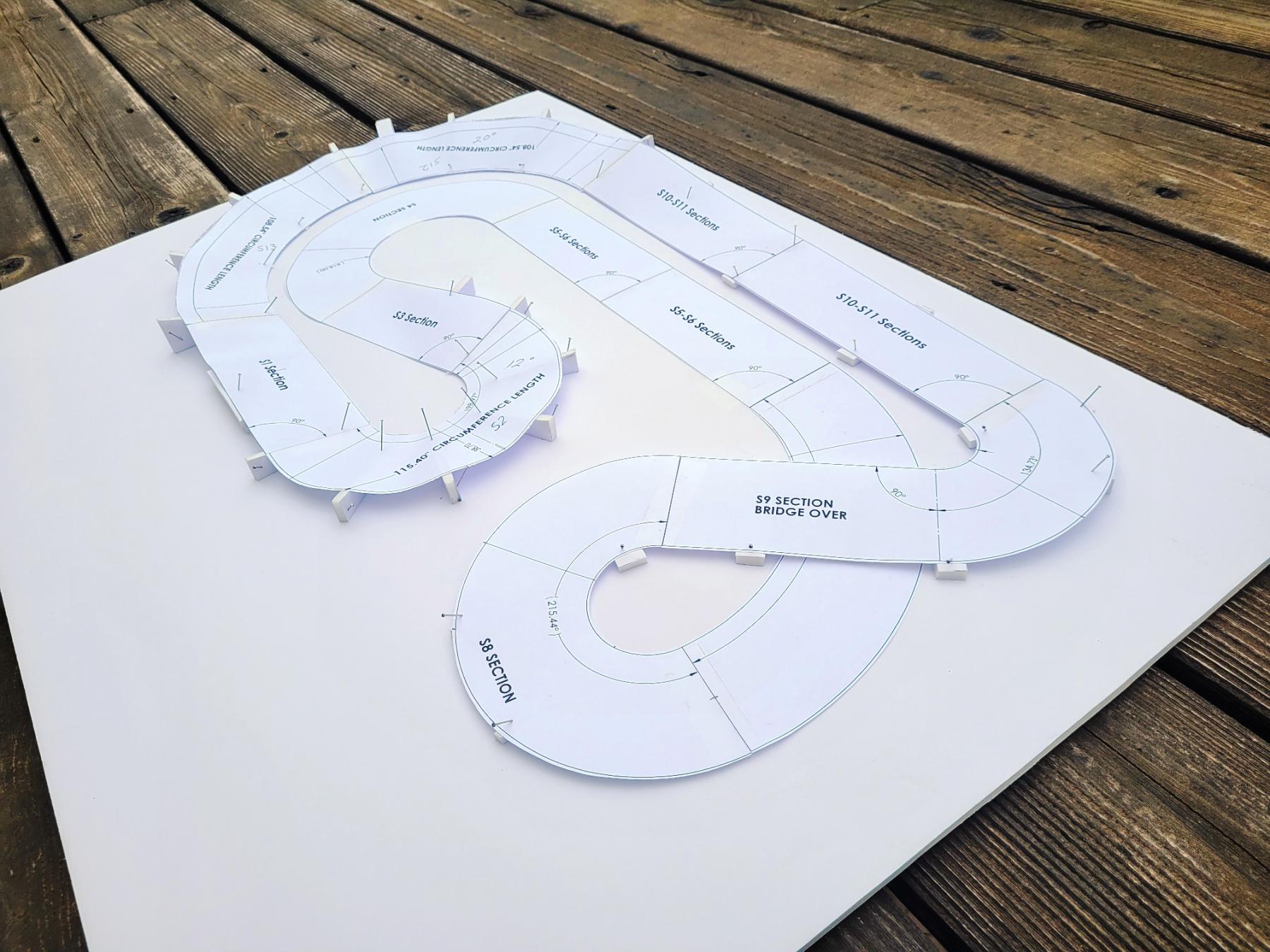

I am looking into getting the section outline panels cut on a CNC router so I have been working on the CAD files for each section.

Well that's all for now.