The only soldering left to do on the chassis (besides soldering in the motor) are the little pan downward stops and plumber rail upward stops.

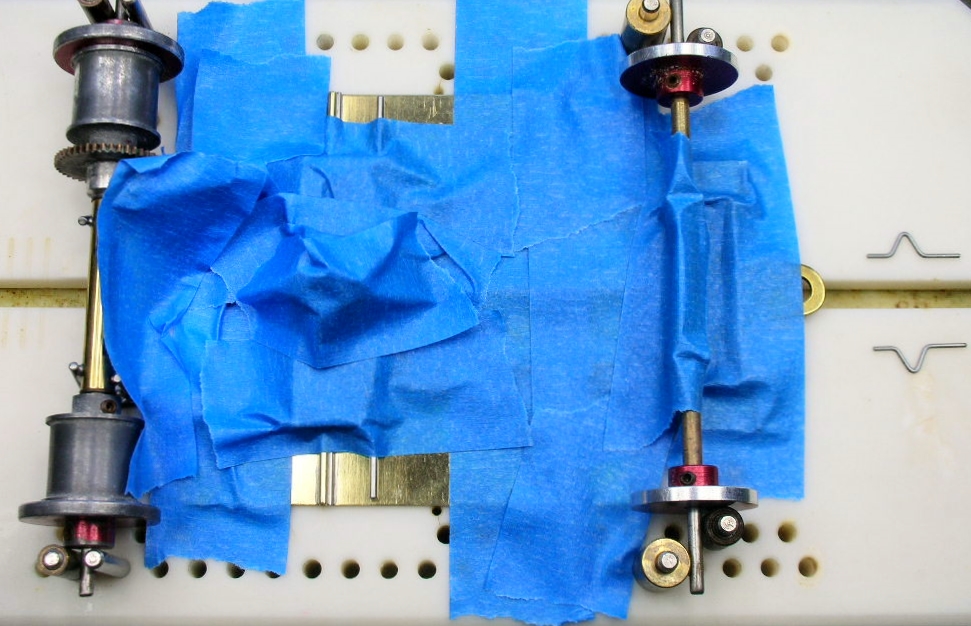

To avoid having to wash and dry the chassis again for soldering in such a small area, I broke out the painters tape. It looks goofy ![]() but worked great and only took a minute to do:

but worked great and only took a minute to do:

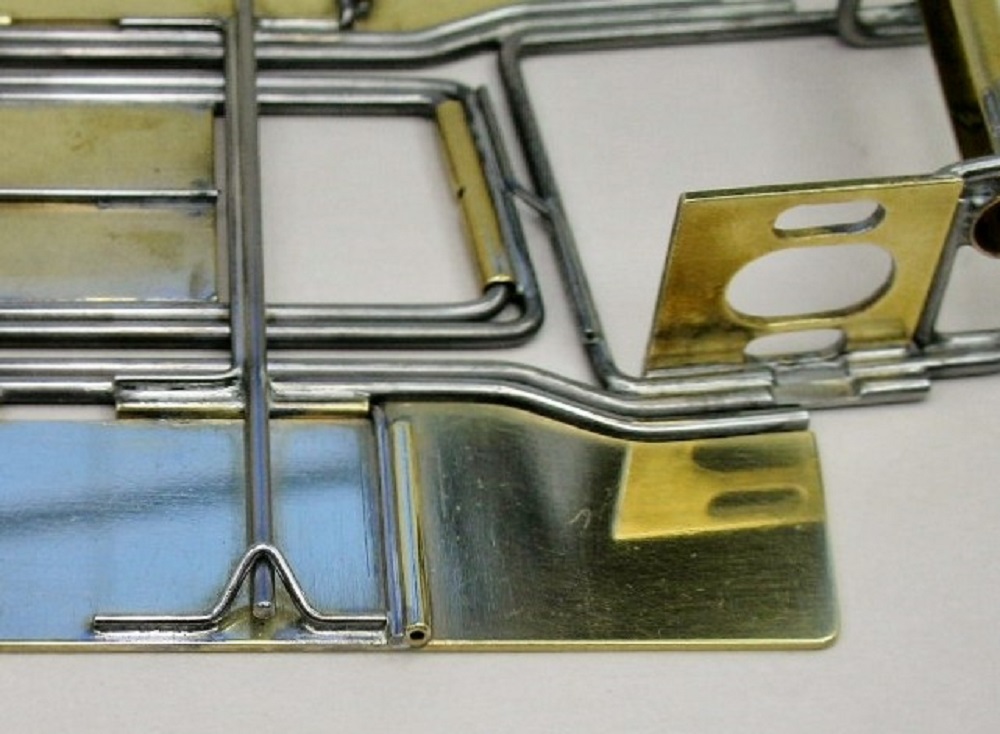

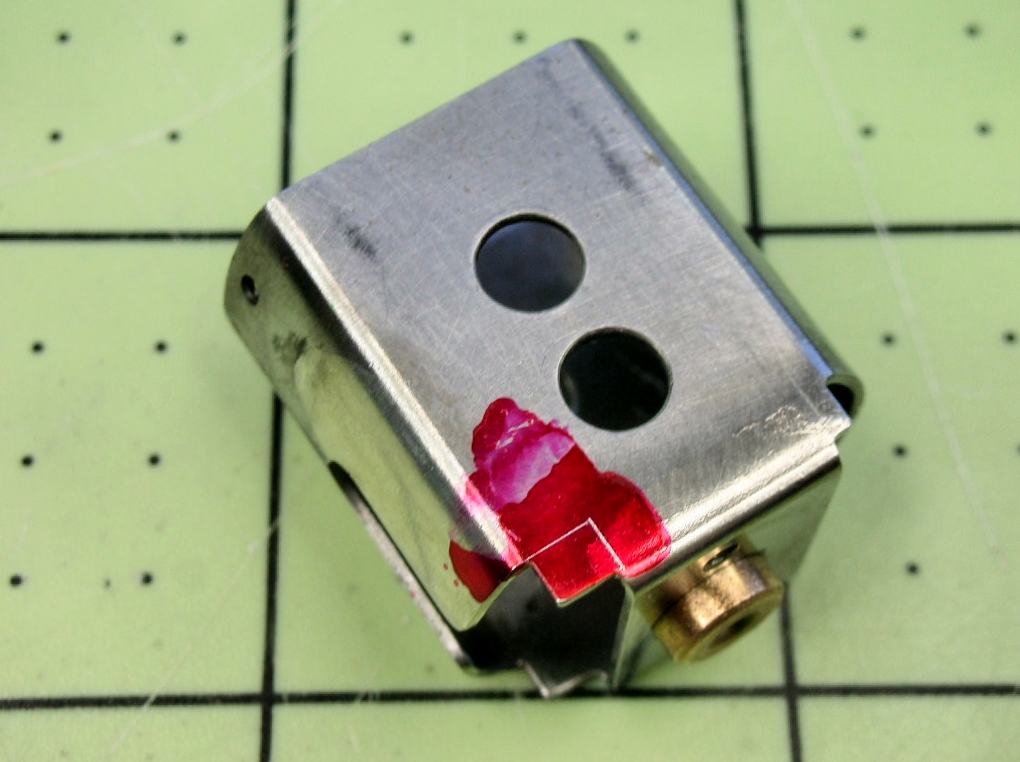

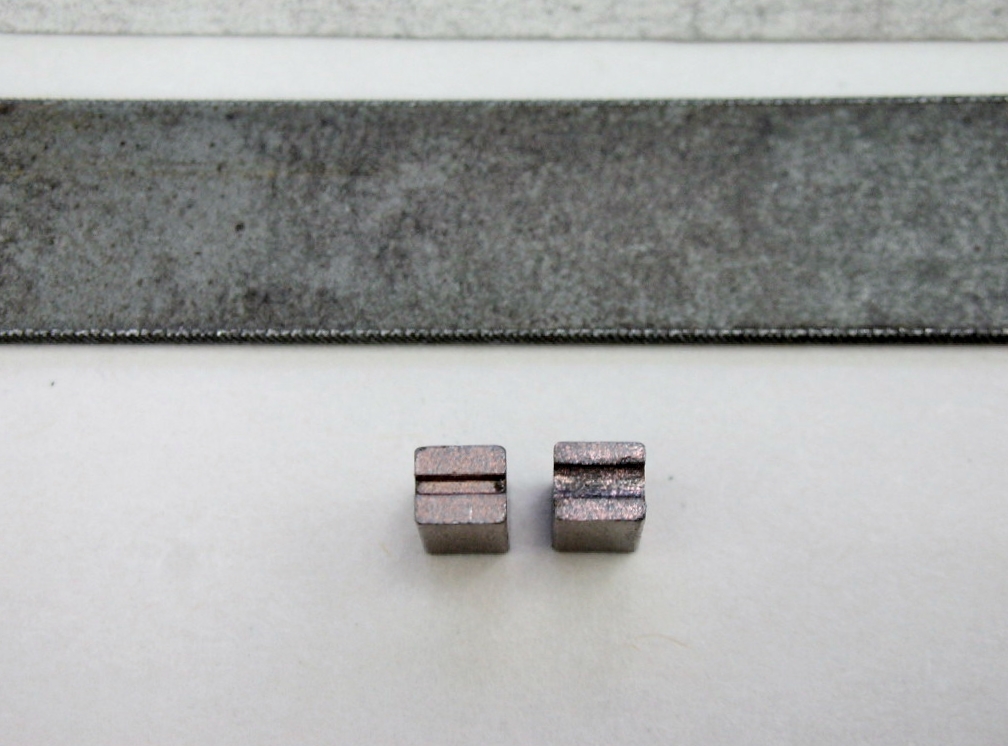

The pan stops:

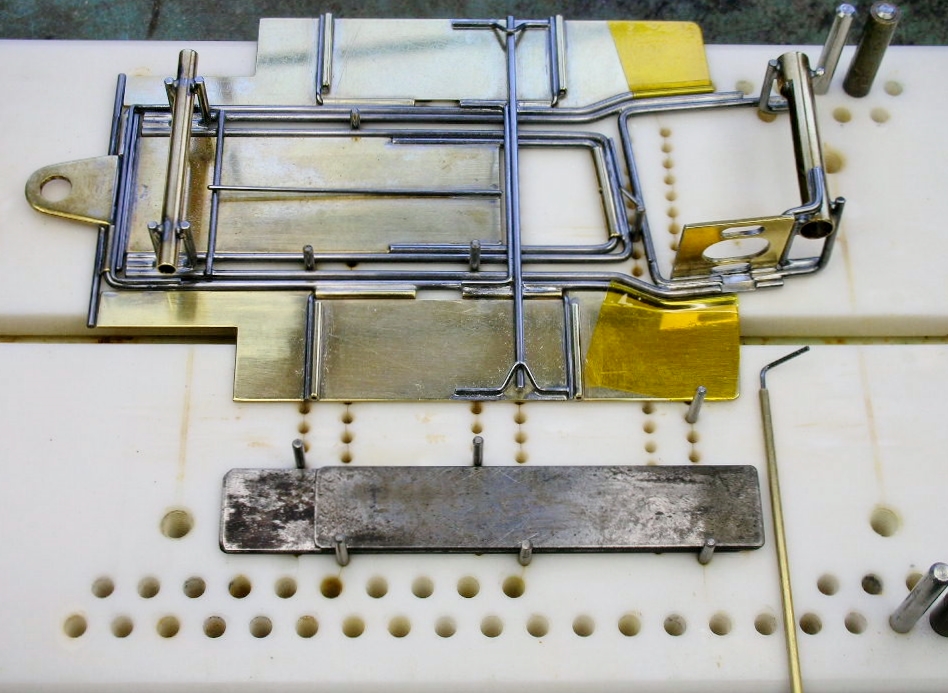

The stops installed, the tape did its job and made cleaning up the small exposed area easy:

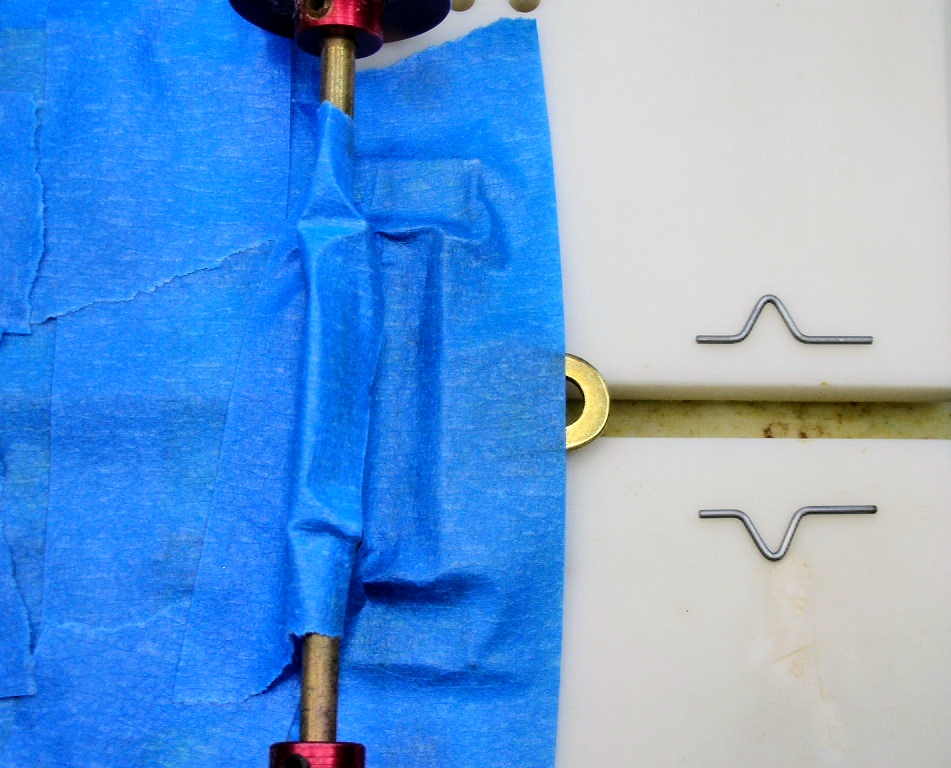

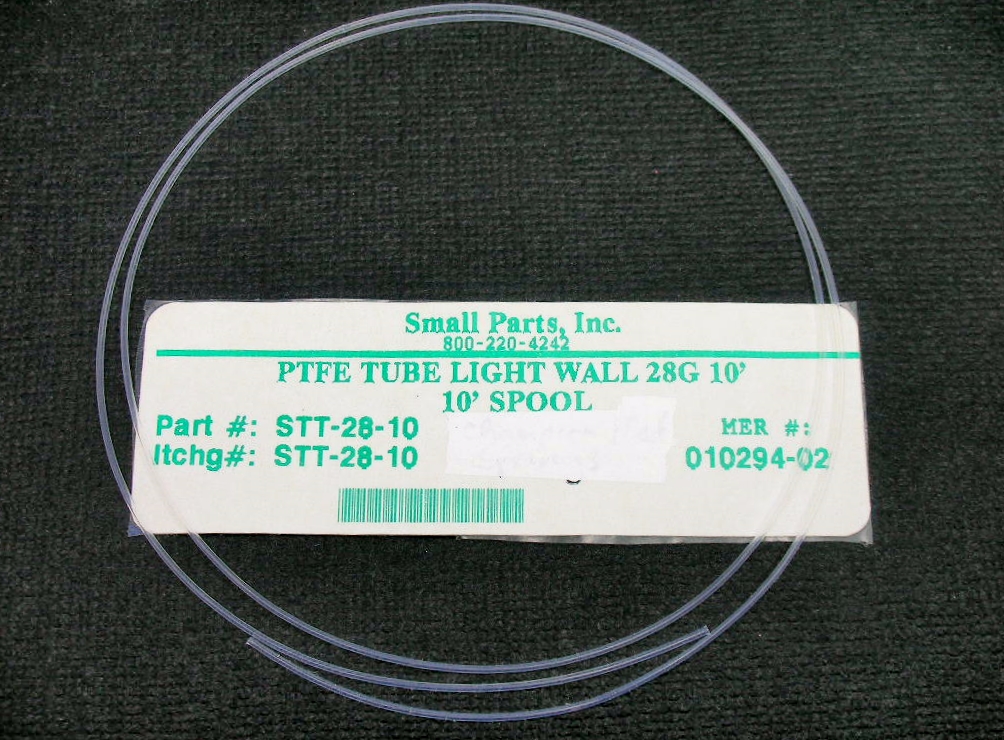

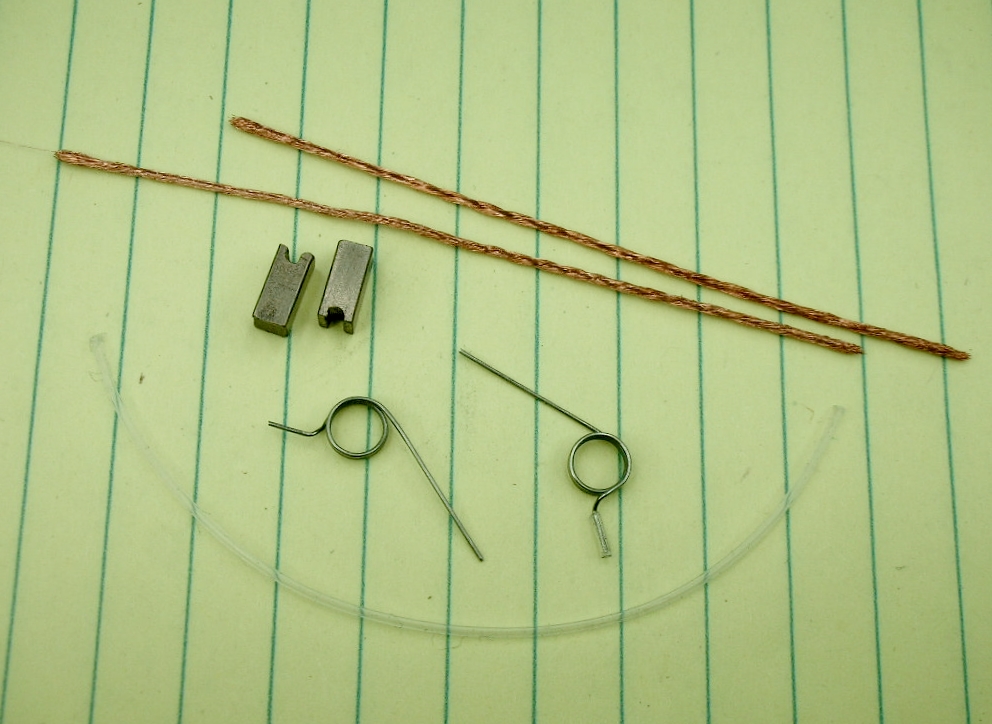

The setup for the unusual plumber rail stops. To hang onto the little .032" L-shaped wire stops while soldering they were slid into a long piece of pin tube and lined up with the jigs pins:

Kapton tape keeps the solder out of where I don't want it:

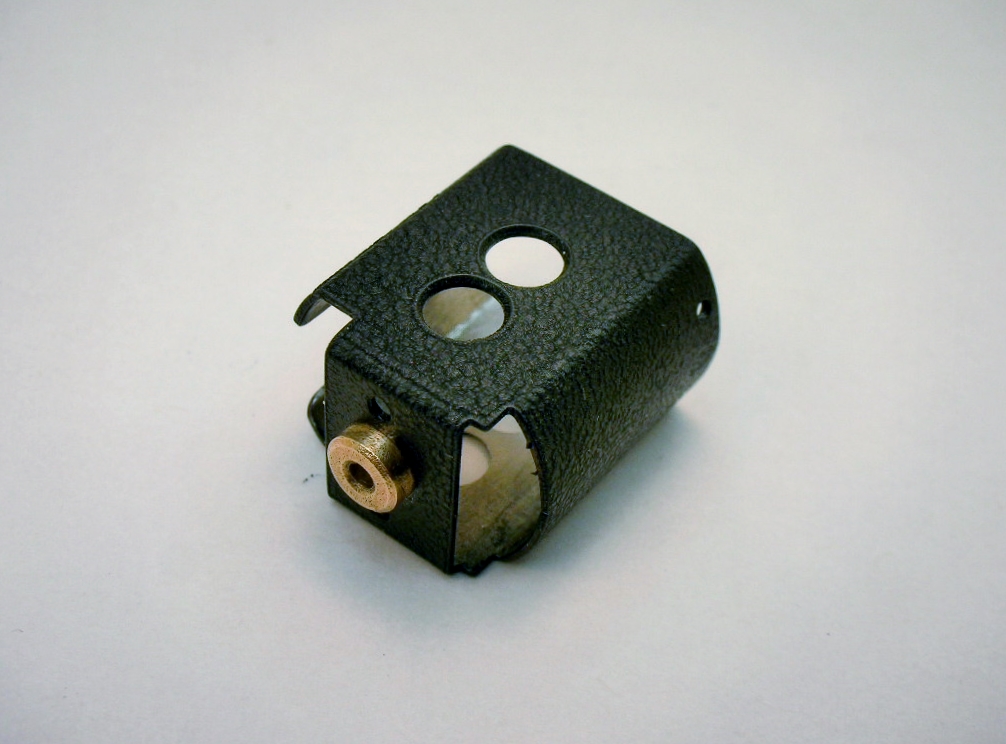

The same setup on the opposite side:

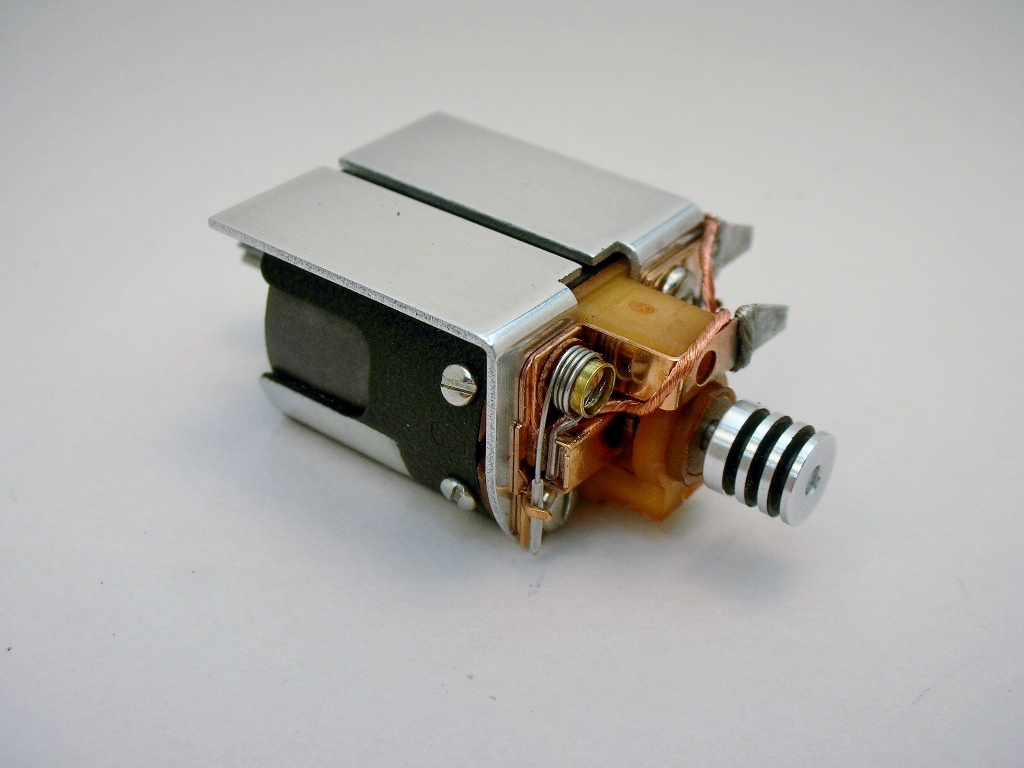

With a final polish the chassis will be done. ![]()

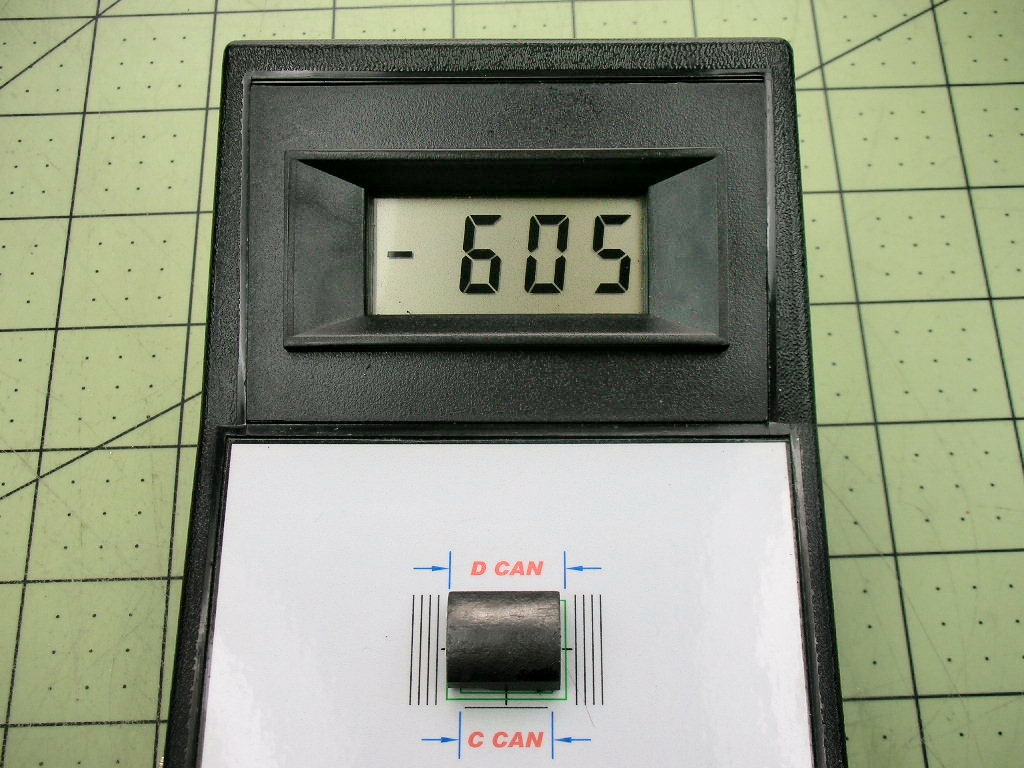

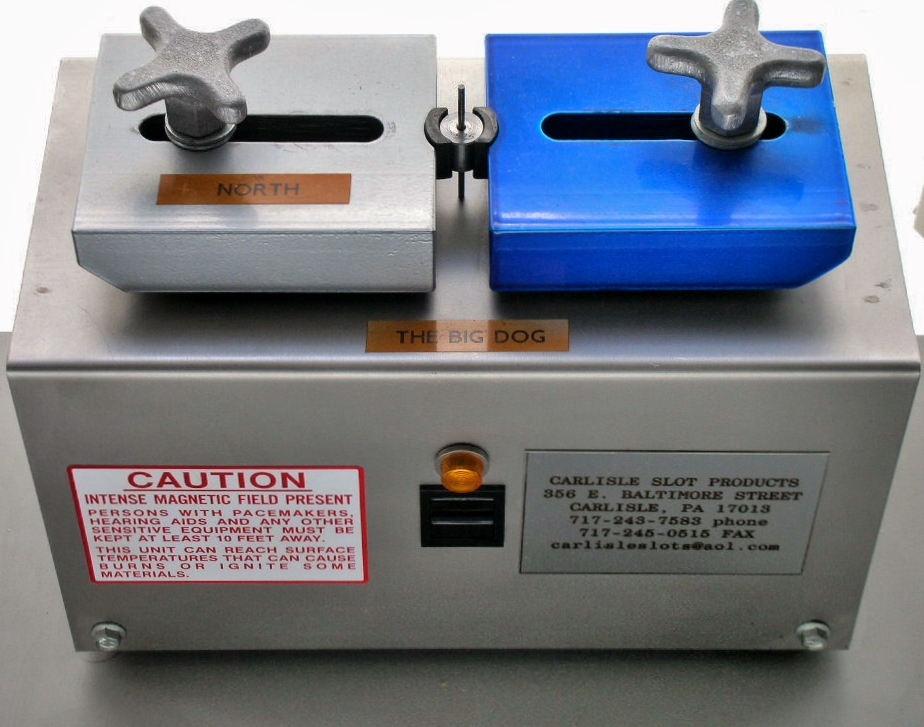

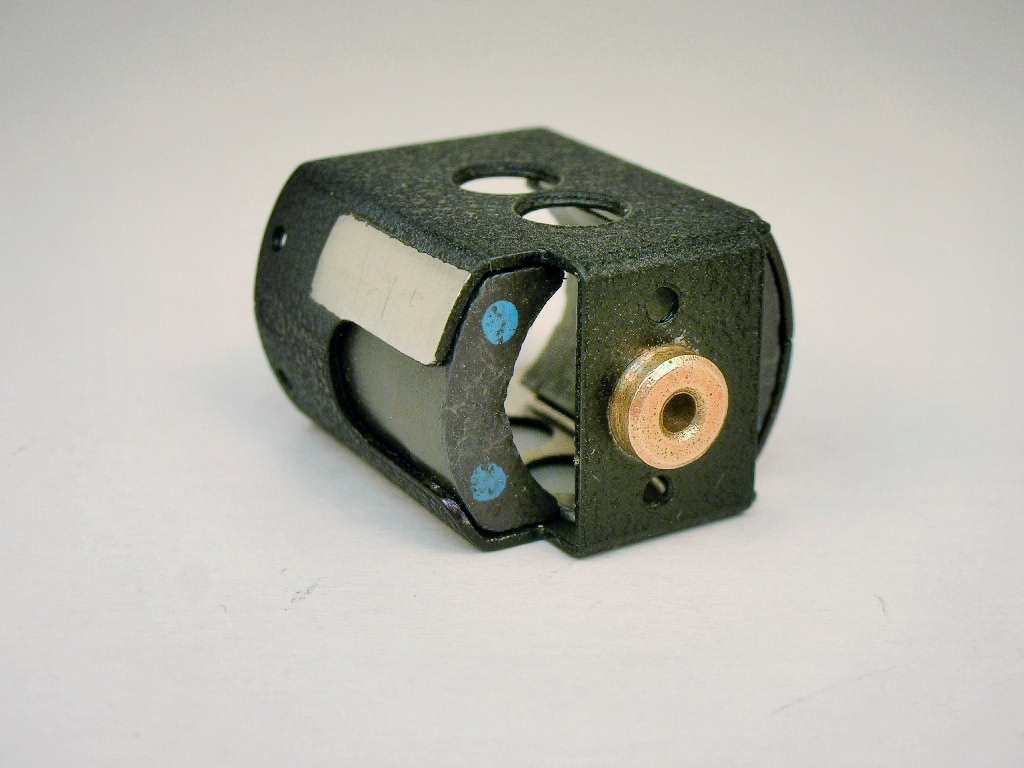

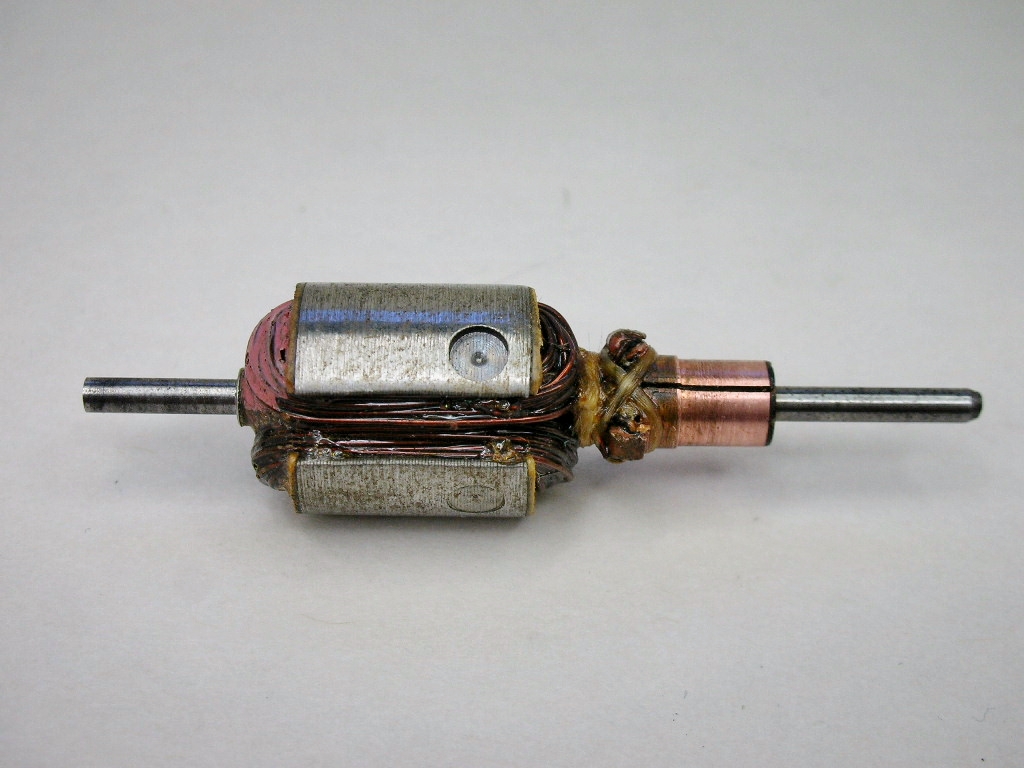

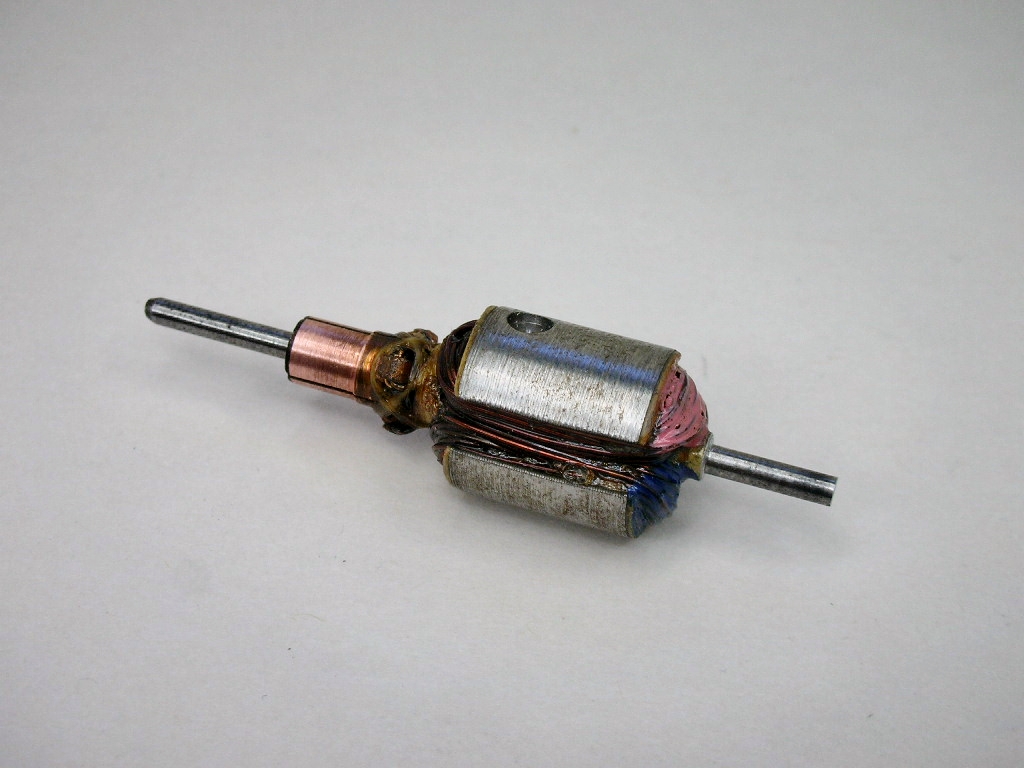

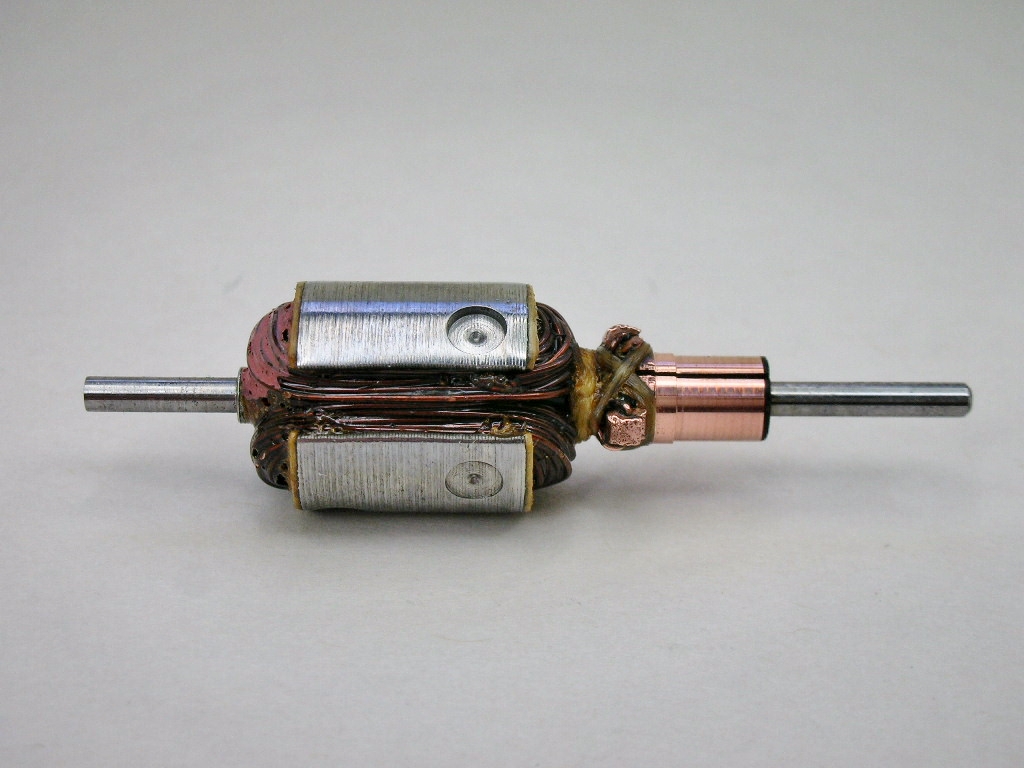

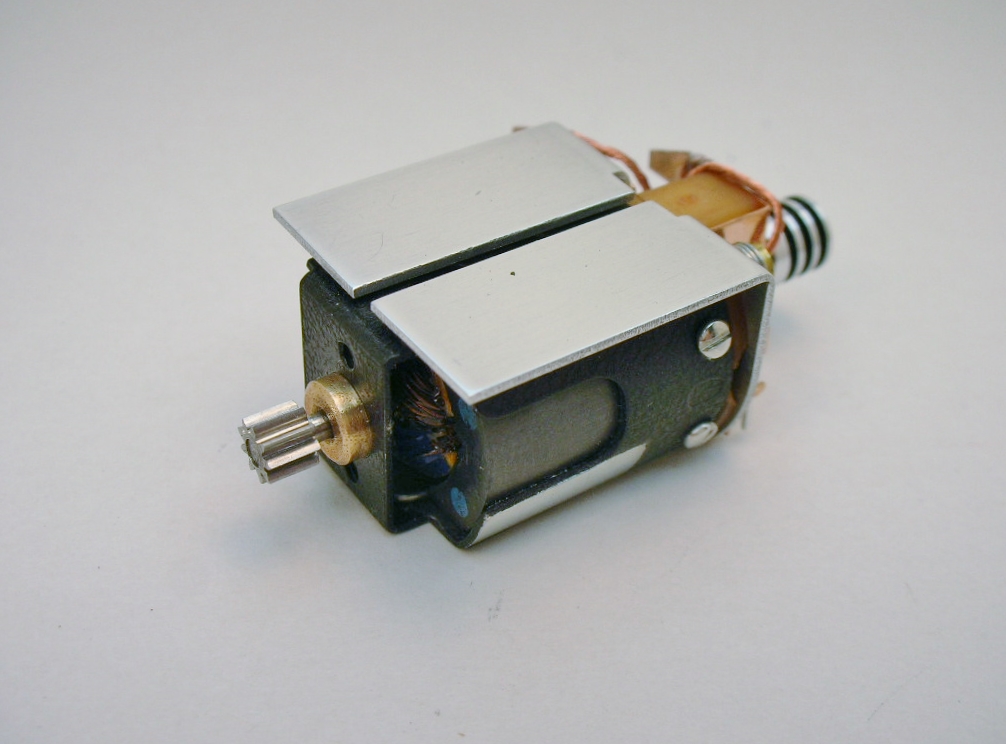

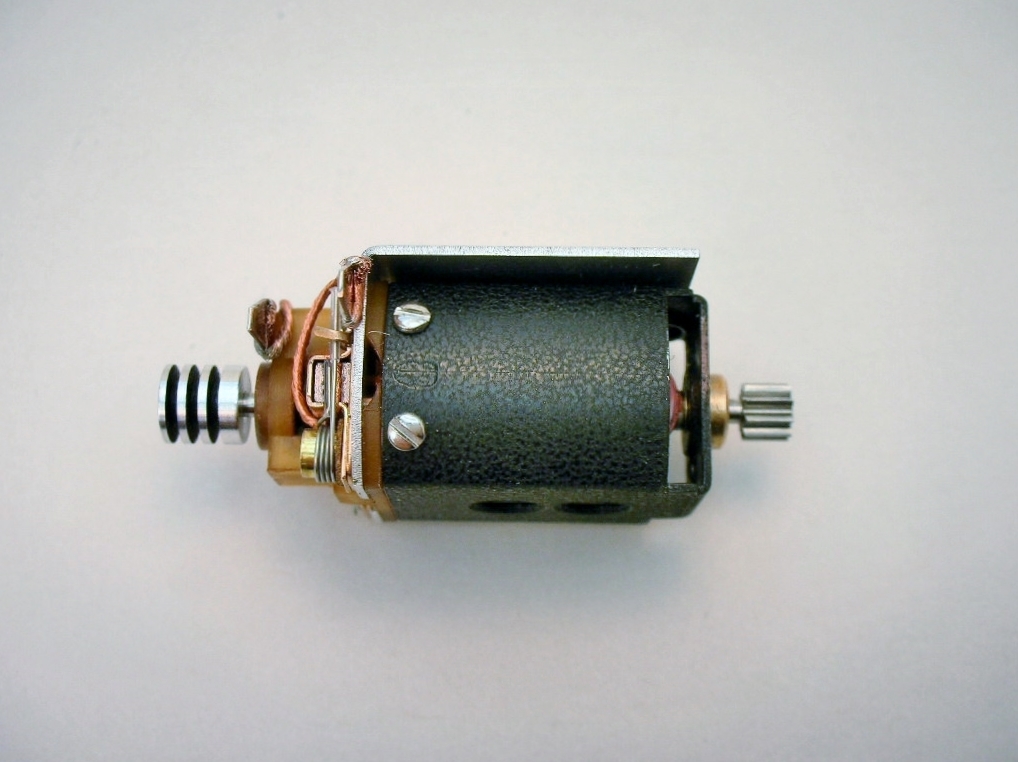

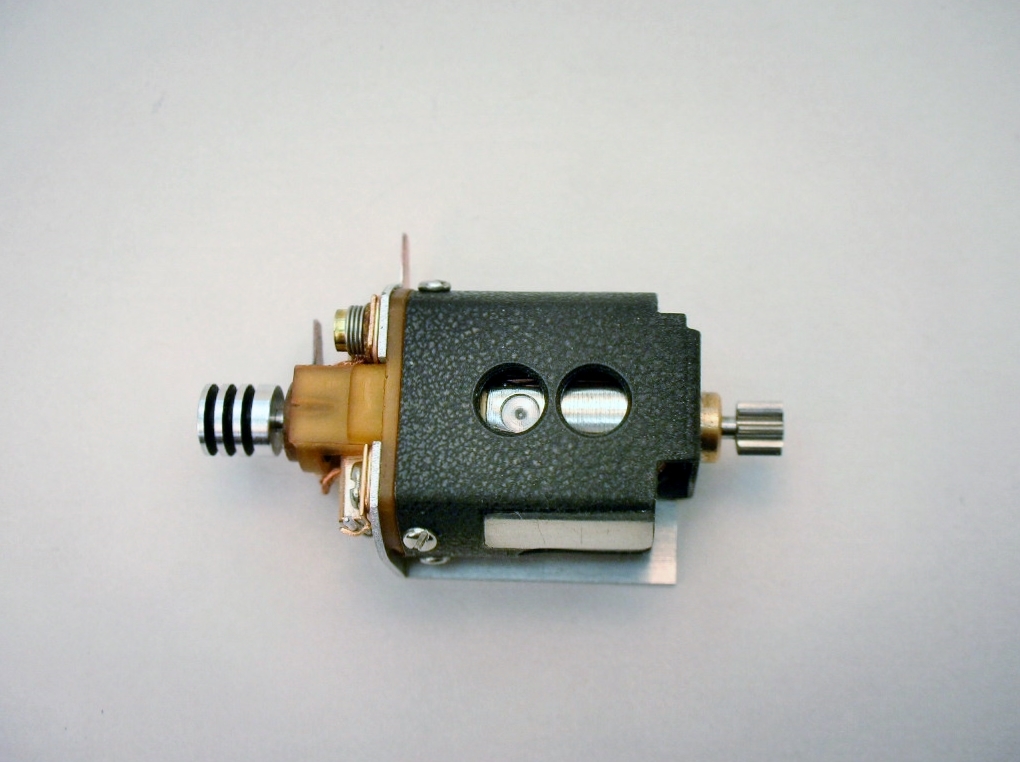

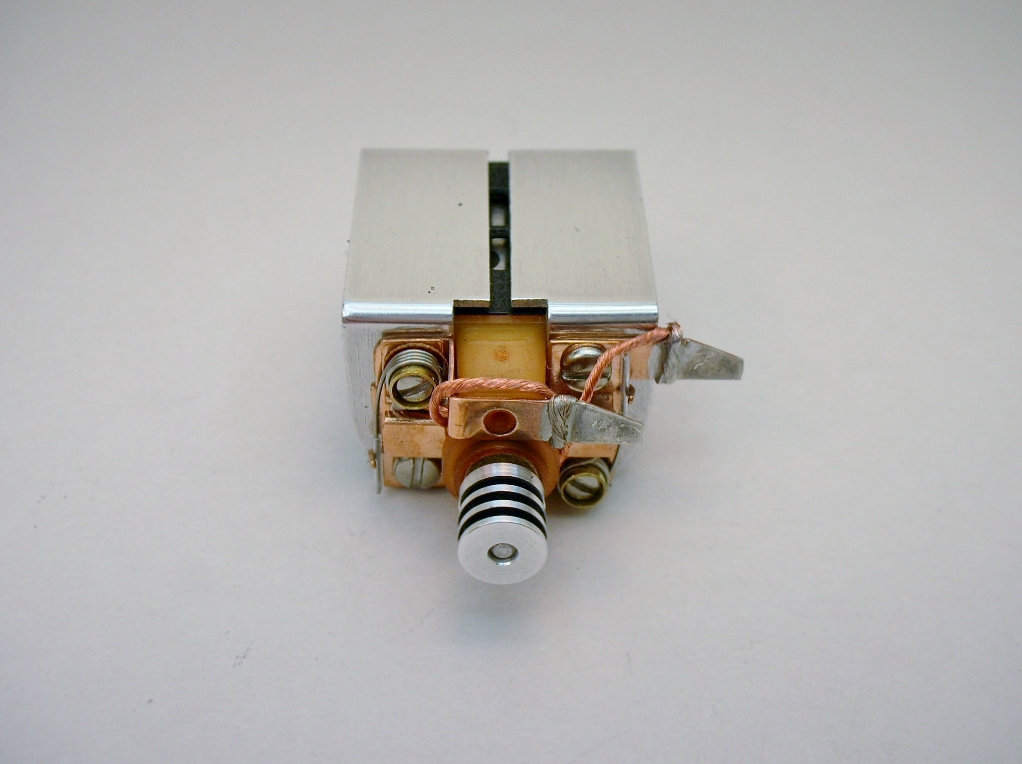

Time to build the motor. ![]()