Then ... I'll give it a try when I build a 'black can'.

BTW:

the ginormous can bushing on the Champ

Weighs in at a porker 1.2+ grams ...

------------

Back to the 'Murabuchion'

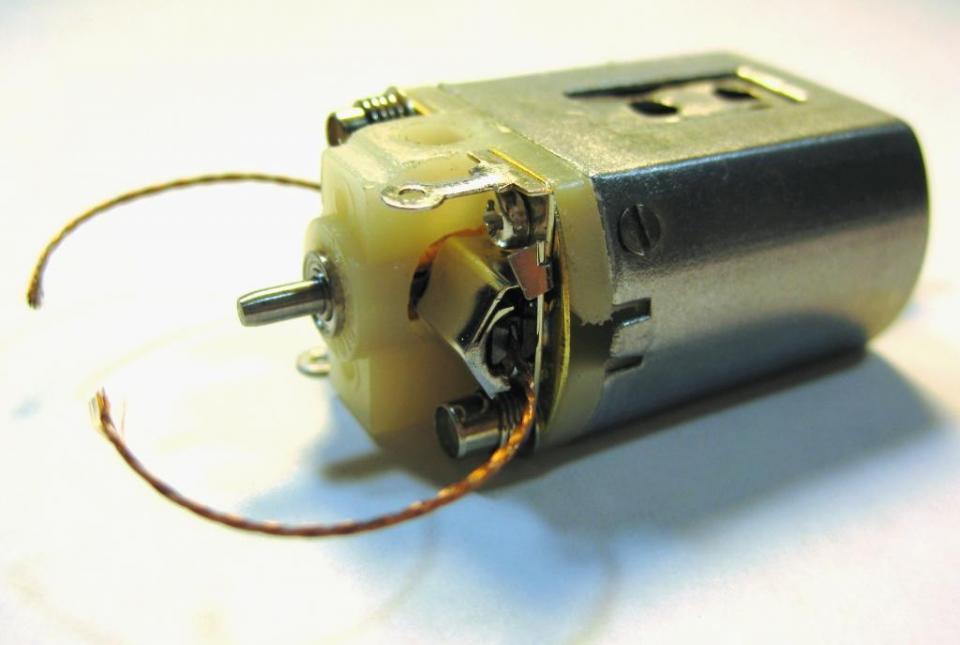

Detailed fit and finish assembly (a.k.a. Blueprinting) took hours. The end bell plastic prep for can fitment and alignment of the hoods and plates was a challenge. If you assemble this stuff out of the bag the result would be 'really crappy'.

John, I went with the 26D brushes running on the big Kirkwood trying to keep it in 67 ... I think 68 is when the little 16s went with the 36D size brushes.

Bill, I don't know what chassis this 'enduro' motor would be good in...? .. What year would this 'stock arm' motor represent ... 67?

Pablo, I changed the whole business end of this motor around ... lol

Paul, and all .. thanks for the comps!

What it be made of?

Mabuchi:

- Can (Russkit 22)

- 26D Brush holders (heat sinks)

- Pent roof holders.

Mura:

- 'Stock 16D replacement' #R12A armature - 50 turns / 30 wire - .400 stack length, 513 dia., .007 lams, Kirkwood com. late 80s.

- "SEMI CAN" Magnetic shield / shim. *

- Stock ceramic "C" Magnets.

Champion:

- End bell Plastic

- Base Plates

- Chrome posts

- Shunted brushes

- Plated 4 coil springs

- Can screws 0-80 undercut FH

I have to change out the 4 coil springs ... way to strong.... for Mura light 3 coils before start-up and break-in. The shunts get routed and soldered at the same time as the lead wires when motor is test fit in a chassis.

![]()