No didn't need that one Pablo  Just those 2 that got picked up by someone

Just those 2 that got picked up by someone

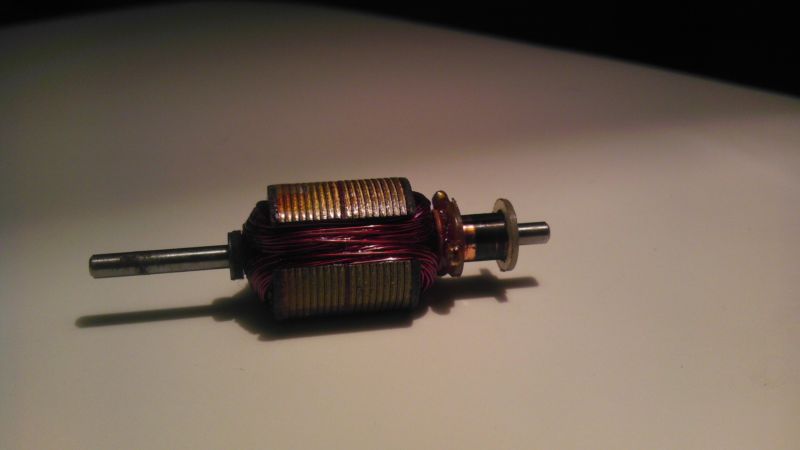

Good to know Don , never run a Pittcan before so only going by previous builds & experiences on here (including the various 6001 powered Dynamic Proxy cars!!) By the looks of it my motor has the Hotter arm in it!

Have been comparing it to pictures that Rick posted when he did the Jerry Hansen '66 Lotus 19 6001 sidewinder  Has the ring to help hold the windings on, haven't measured it yet but does indeed look like the hot one ..Pictures to follow soon.

Has the ring to help hold the windings on, haven't measured it yet but does indeed look like the hot one ..Pictures to follow soon.

May just drill a few holes for now then & just blueprint it

36D or Kemtron.... very nice ideas for some different & cool R&C cars