Second "rough cut" on the rears:

Posted 09 October 2015 - 12:28 PM

Holy smokes, Pablo. Checking for straightness on the main rails with a dial indicator. ![]() You've got me beat there!

You've got me beat there! ![]() I thought I was being fancy rolling the rails on a flat to check for straightness.

I thought I was being fancy rolling the rails on a flat to check for straightness. ![]()

Bent mail rails do suck...

Onward, Pablo... ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

Posted 09 October 2015 - 01:14 PM

Posted 09 October 2015 - 02:46 PM

Thanks, guys. ![]()

Getting off to a slow start; last week I was sick, now I'm struggling with planning phase details I should have worked out weeks ago. ![]()

I now realize the magazine article doesn't address three big issues: wheelbase, guide lead, and if the rails are tapered towards the front or not.

And I thought I had the perfect steel washers for the axle tubes, and didn't.

Nothing is ever easy at The Wolcott Ranch, so I'm used to it. ![]() One good thing, I found the "secret drawer" at Lowe's stashed with K&S stuff.

One good thing, I found the "secret drawer" at Lowe's stashed with K&S stuff. ![]()

Thanks to some help from my good friends, I may actually solder something here soon.

Paul Wolcott

Posted 09 October 2015 - 07:11 PM

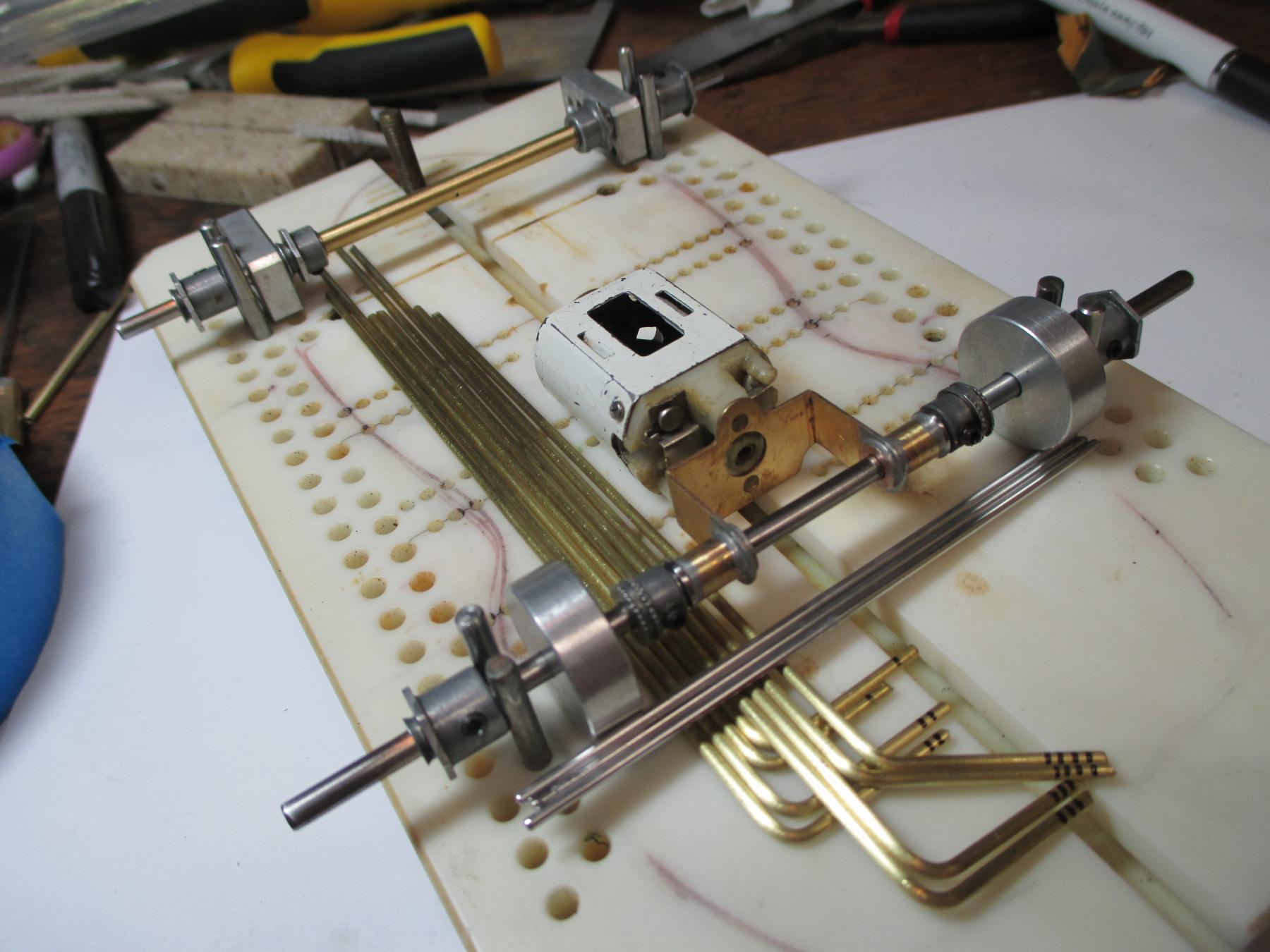

Found steel washers, perfect ID (slightly bigger than the axle) but OD was a little bigger than I wanted (.310"). So I turned 'em down a little, to about .265". I'll polish them after they are soldered to the tube pieces.

Genuine Russkit 495 bracket

- modified to accept inside rails

- axle tubing holes hogged out to 7/32" with a Uni-Bit

- motor bushing and mounting holes slightly enlarged and countersunk

- flattened, straightened, and sanded clean

My flag blueprinting mini-jig is a nice tool for this.

Motor bracket is ready.

Paul Wolcott

Posted 09 October 2015 - 08:28 PM

Wheelbase and guide lengths are usually dictated by the body used. I haven't had the body you plan to use, so I'd say measure it twice, cut once.

If I was building a generic 1/24 F1 chassis, i'd use a 4.25" wheelbase and a .75" guide lead. These dimensions would fit the majority of the 1/24 cigar-shaped F1 bodies.

Nope, this Team Russkit car doesn't use tapered rails. Construction photos and the Martin Windmill cars will back this up. ![]()

Posted 09 October 2015 - 09:03 PM

Wheelbase and guide lead lengths are usually dictated by the body used.

Paul Wolcott

Posted 10 October 2015 - 09:09 AM

The open wheel cars back then, as today, were a handful to race but a ton of fun. A 4.5 inch wheelbase and as long a guide as the body allowed made them easier to race.

Car Model rules may have been strict enough to keep the wheelbase close to the original. Otherwise Bill is close to correct.

Posted 10 October 2015 - 09:25 AM

The orange wheels are slightly wider than the blacks, so I planned tube lengths for them at 3.00".

Twin Slick 7 20 thou steel spacers on each side to allow a needle oiler to lube the washer faces.

The black wheels will use an .063" against the hubs and a single Slick 7 against the washers for 3.00".

By adding an extra .063" spacer on both sides to either setup, the width will be about 3-1/8" or 79.4 mm.

Just to triple-check my math, I mocked it all up.

Paul Wolcott

Posted 10 October 2015 - 09:46 AM

The wheelbase of the real Honda was 2390 mm, which will give a scale wheelbase of around 4.00"... too short maybe for good handling.

Posted 10 October 2015 - 09:59 AM

Noose measured the body today; wheelbase will be 4.00" and guide lead 5/8".

Paul Wolcott

Posted 10 October 2015 - 10:17 AM

Close to scale wheelbase then... very good.

Posted 10 October 2015 - 10:38 AM

Whoo! That be short.

Don

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

Posted 10 October 2015 - 10:50 AM

Pablo,

Since the rear tire diameter of the car is known, use the cover photo to calculate the wheelbase of the car shown there, just as a double-check. Or use a pic from the article.

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

Posted 10 October 2015 - 05:22 PM

Washer ends pre-polished with 2000 sandpaper

.300" tube pieces go through the bracket sides and up against the bushing flanges.

When I torched the bracket/bushing/tube joints (both at the same time) the acid and solder wicked out into the washer/tubing ends.

Good thing I had them secured and in perfect position at the time ![]() (Thanks, dc-65x.

(Thanks, dc-65x. ![]() )

)

I added a little more solder to them for aesthetics.

Care must be taken to ensure the washers don't end up touching the axle and rob horsepower

I'd like to thank a lot of people for helping me get this car started, dc-65x, Tony P, Bill from NH, John Havlicek, and especially Noose.

If I forgot anybody, get in line behind Noose for an opportunity to throttle me - I've been driving him crazy with questions and favors for two days now. ![]()

Paul Wolcott

Posted 10 October 2015 - 05:26 PM

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

Posted 10 October 2015 - 05:53 PM

You're closer to him than the rest of us are. You might not be off the hook yet. ![]()

Posted 10 October 2015 - 06:02 PM

BTW, Pablo, is that all you got done today? LOL...

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap

Posted 10 October 2015 - 06:29 PM

Correct, sir. ![]()

Paul Wolcott

Posted 11 October 2015 - 04:14 AM

Posted 11 October 2015 - 02:02 PM

Paul Wolcott

Posted 12 October 2015 - 03:25 PM

Paul Wolcott

Posted 12 October 2015 - 04:32 PM

Gregory Wells

Never forget that first place goes to the racer with the MOST laps, not the racer with the FASTEST lap