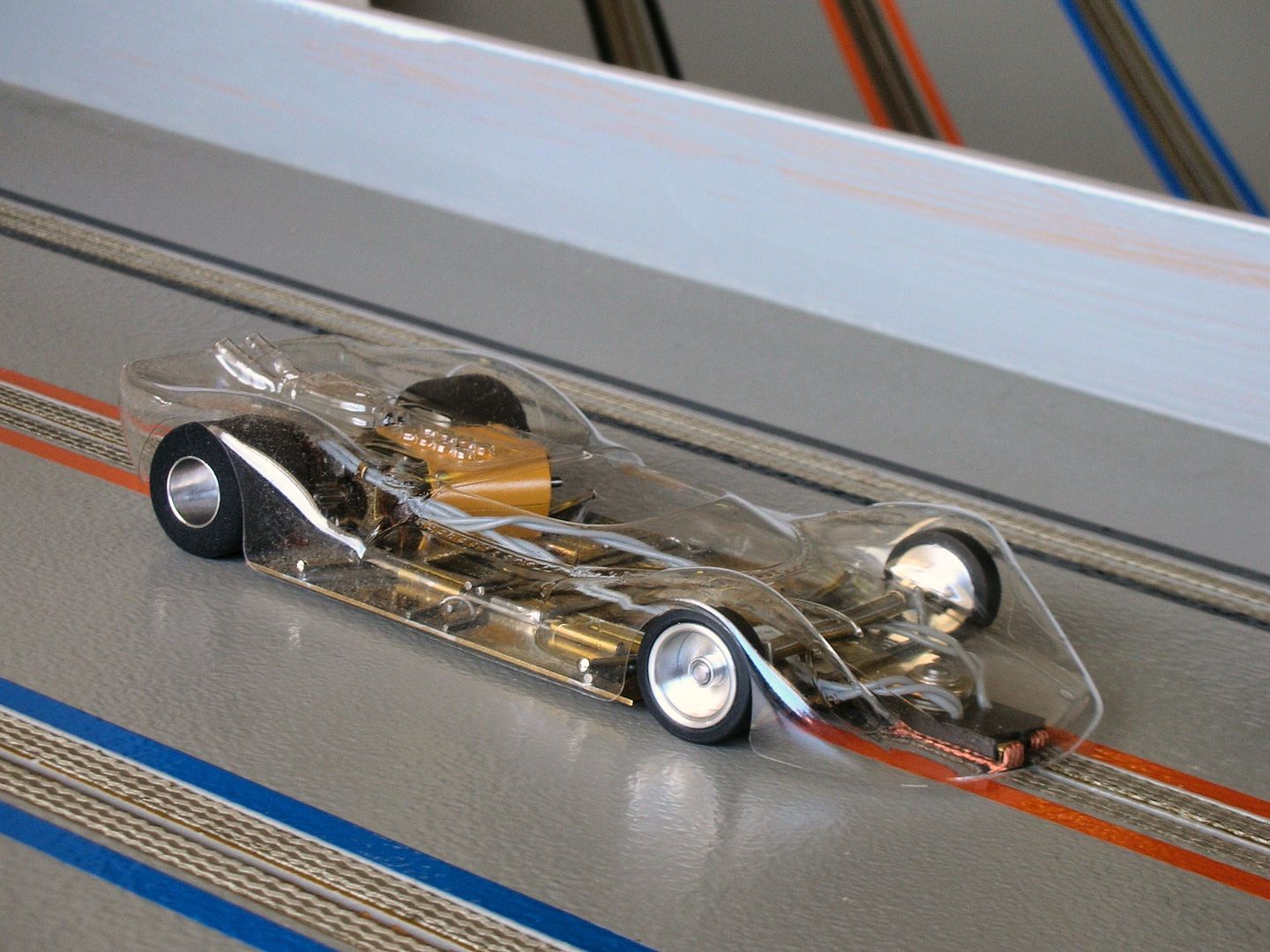

Roll on the track test, just know it's gonna fly !

Howie's '68 world record TQ at "Cough City"

#76

Posted 11 July 2016 - 02:23 PM

Roll on the track test, just know it's gonna fly !

#77

Posted 11 July 2016 - 03:03 PM

Steve/Rick (in my best New York accent)...youz guys scare me (and I mean that in a really good way!).

-john

#78

Posted 27 July 2016 - 10:49 AM

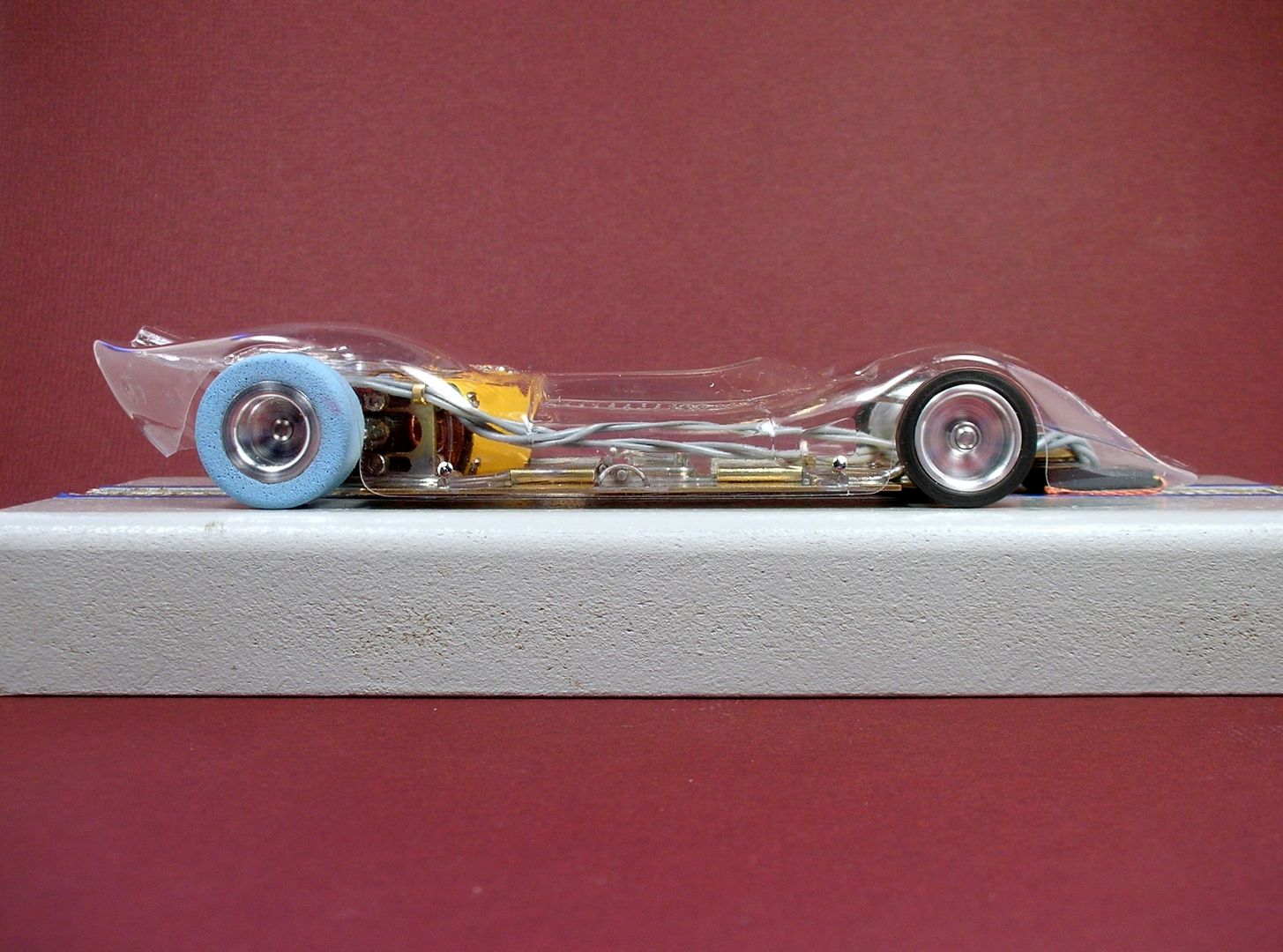

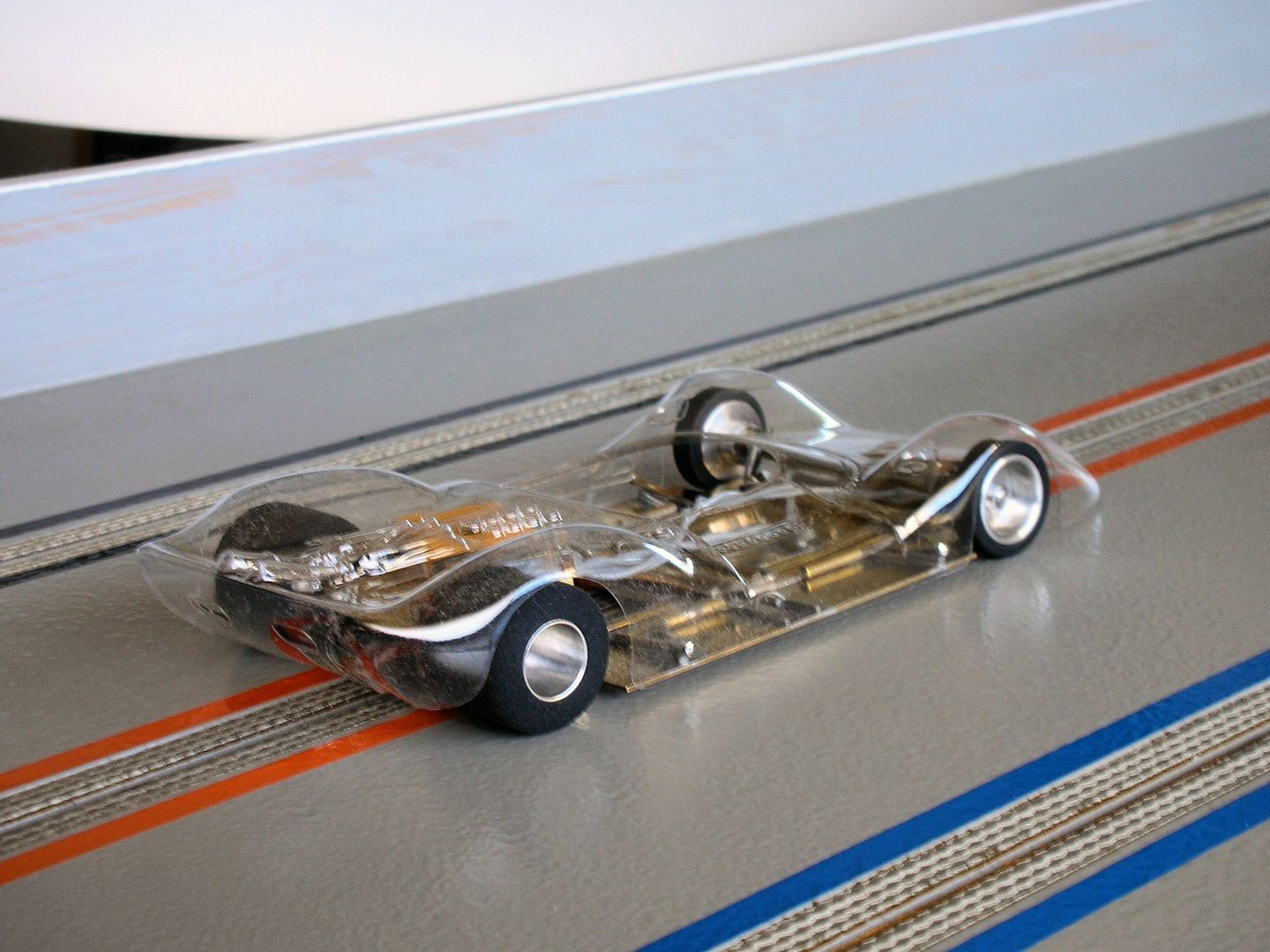

I've been working to get a Dynamic Lotus 40 body (TrueScale reproduction) Howie says he ran to fit on his car............and it has been a bit of a struggle. The body was designed and manufactured before there was such a thing as an anglewinder slot car. The rear fenders are not wide enough to accommodate an anglewinder's spur gear and it stops the body from fitting down over the chassis "korrectly". ![]()

Howie told me that he would not only flare fenders on his bodies if necessary but make any little clearance "bumps" needed to make a body to work. OK...........all this body needed was a tiny little bump over the gear.........no problem. ![]()

Since I like "gizmos" I decided to upgrade from the "hot spoon" to this fancy lad piece:

It's like a soldering iron with interchangeable tips:

I fitted the roundy thingie in the middle above and hooked up the gizmo to my soldering rheostat to control temperature.

On a vintage Butyrate plastic this would have really been doable. However, I am using this LEXAN body:

I tried and tried to get this to work on scraps from the body. I couldn't get it to work. The Lexan would just sit there and laugh at me. As I raised the temperature nothing happened until.......BAM! The plastic would suddenly melt! ![]()

I'm not saying this can't be made to work with Lexan, I'm saying I can't make this work with Lexan. ![]()

OK......if I can't make a bump, I'm make a hole!

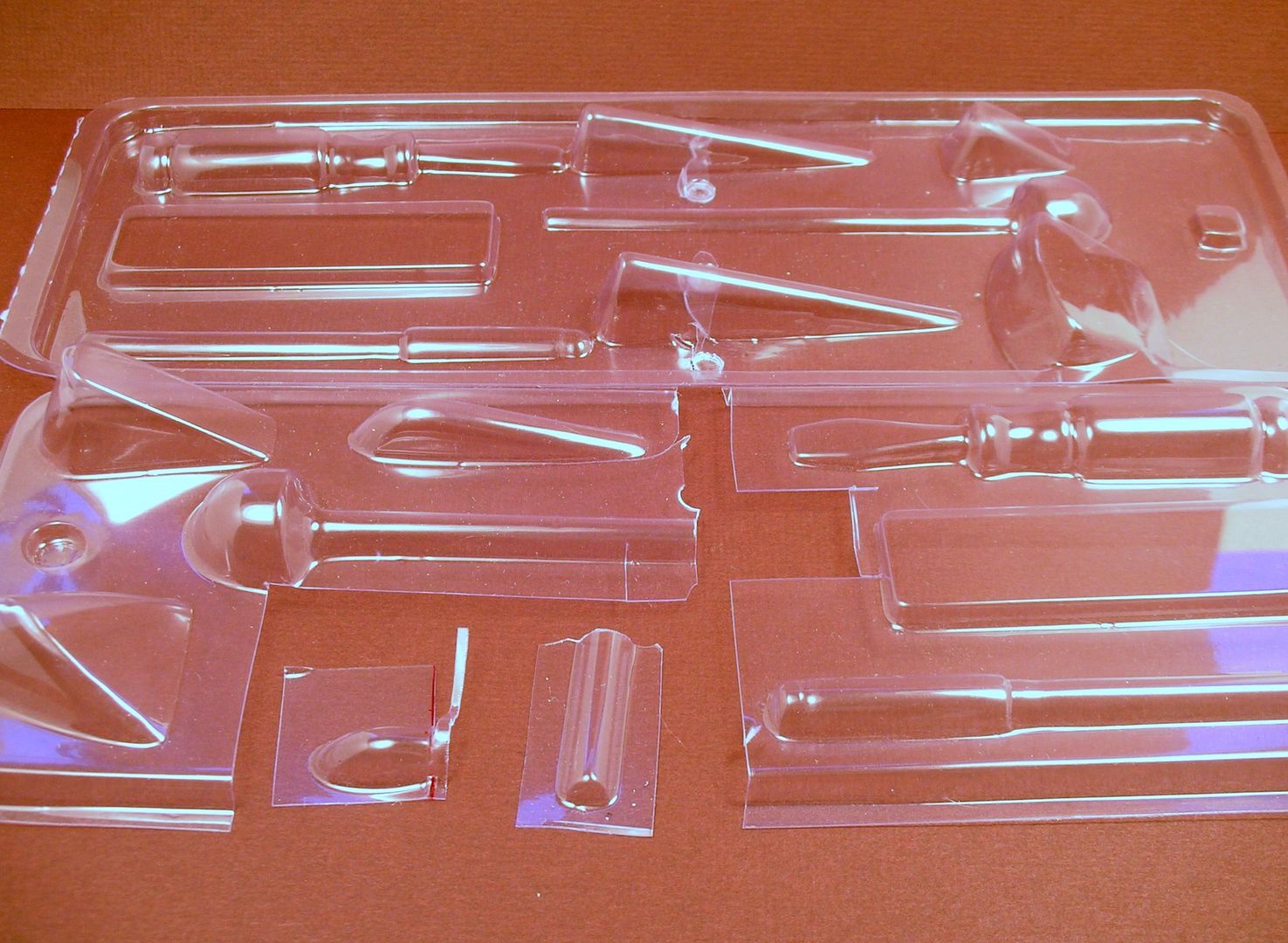

But the rules of the time won't allow this. ![]() I need to cover up the hole. I talked this over with Howie and Steve and came up with a good use for the packaging for that "gizmo" I showed above:

I need to cover up the hole. I talked this over with Howie and Steve and came up with a good use for the packaging for that "gizmo" I showed above:

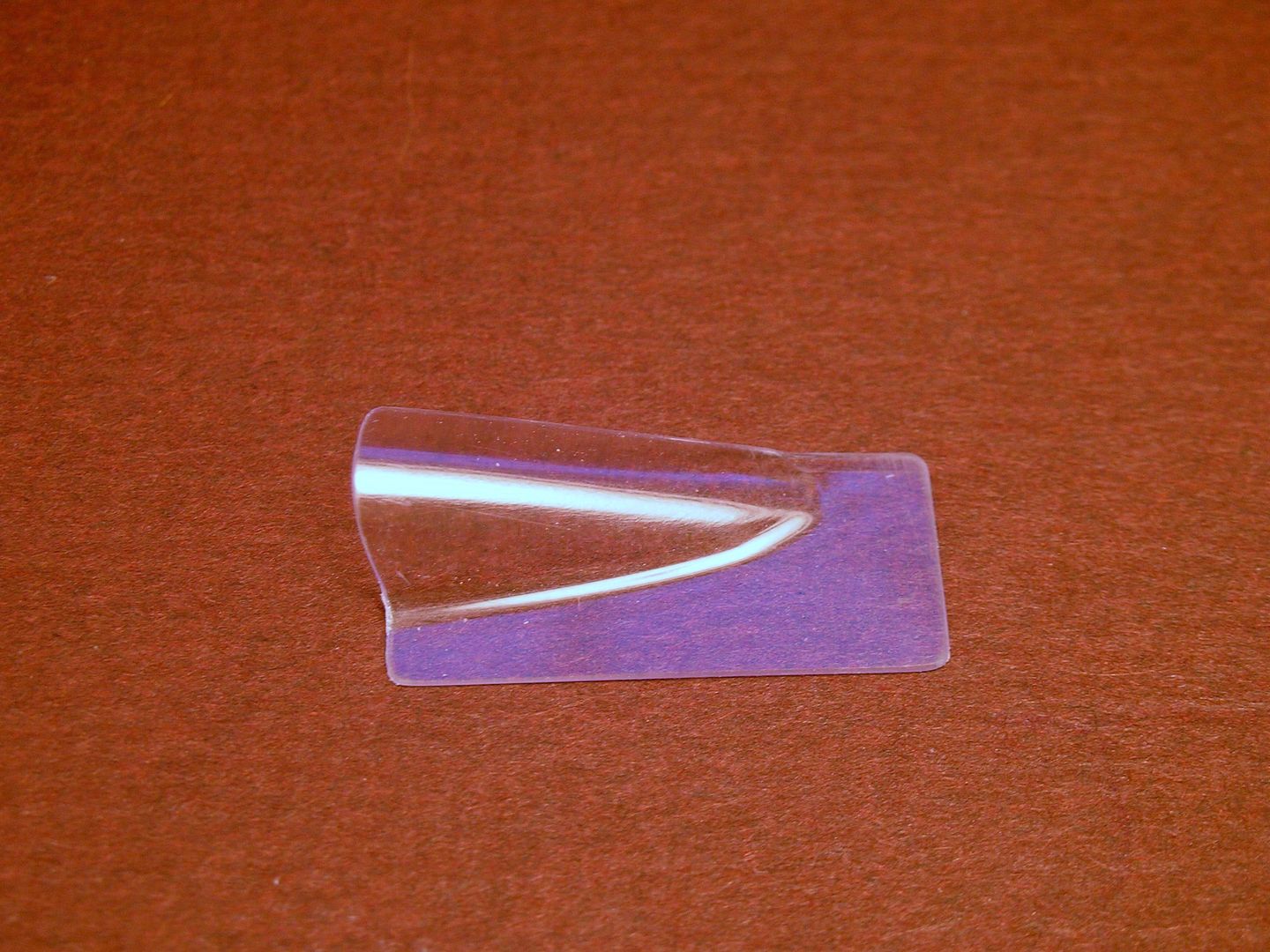

I made a little scoop to cover the gear hole:

Here it is sitting in place:

Howie likes his bodies mounted LOW........really LOW. I've got this one slammed as far as possible:

I installed the narrowed Alpha Pharana rear tires and hit the track:

The motor and those super smooth Weldon gears really sound great at full tilt boogy. ![]()

I've finally got this project ready for Howie and Noose to decide how it should be painted. ![]()

- slotbaker, Jencar17, Pete L. and 2 others like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#79

Posted 27 July 2016 - 11:16 AM

What a cool solution Rick. Didn't know that about Lexan... and your soldering kit is very neat as well...

Don

#80

Posted 27 July 2016 - 11:24 AM

Thanks Don. It could very well be just ME and Lexan. I got frustrated and found another solution. ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#81

Posted 27 July 2016 - 11:29 AM

I've had very limited experience trying to "flare" lexan; I failed also. Butyrate(sp?) on the other hand, flares "real gud"... easy to overheat, though, and wind up with a "sag" instead of a "flare".

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#82

Posted 27 July 2016 - 12:22 PM

Hi Rick, Looks GREAT! Should be a real runner. Can't say you didn't try to make that bubble !!

#83

Posted 27 July 2016 - 01:49 PM

Custom gear cooling induction scoop ![]()

Paul Wolcott

#84

Posted 27 July 2016 - 03:20 PM

I'll never look at blister packaging the same way again.

- Half Fast likes this

"If you have integrity, nothing else matters, and if you do not have integrity, nothing else matters."

Robert Mueller, special counsel (2013)

"... because people have got to know whether or not their president is a crook."

Richard M .Nixon, Nov 17, 1973

"Fool me once, same on... shame on you. Fool me... you can't get fooled again."

George W. Bush

#85

Posted 27 July 2016 - 03:26 PM

My buddy Rodney taught me about blister packaging. He's made some amazing things out of them. ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#86

Posted 27 July 2016 - 04:37 PM

Recently I spotted a plastic piece in the trash I had taken something out of.

Thought it would make a slick looking 1/43 body shell. The thought of building a car for it crossed my mind.

It looked sooo much like a little Thingie body. Next time I'll cut the plastic with more care ![]()

Paul Wolcott

#87

Posted 28 July 2016 - 06:03 AM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#88

Posted 28 July 2016 - 09:44 AM

Hi Tony,

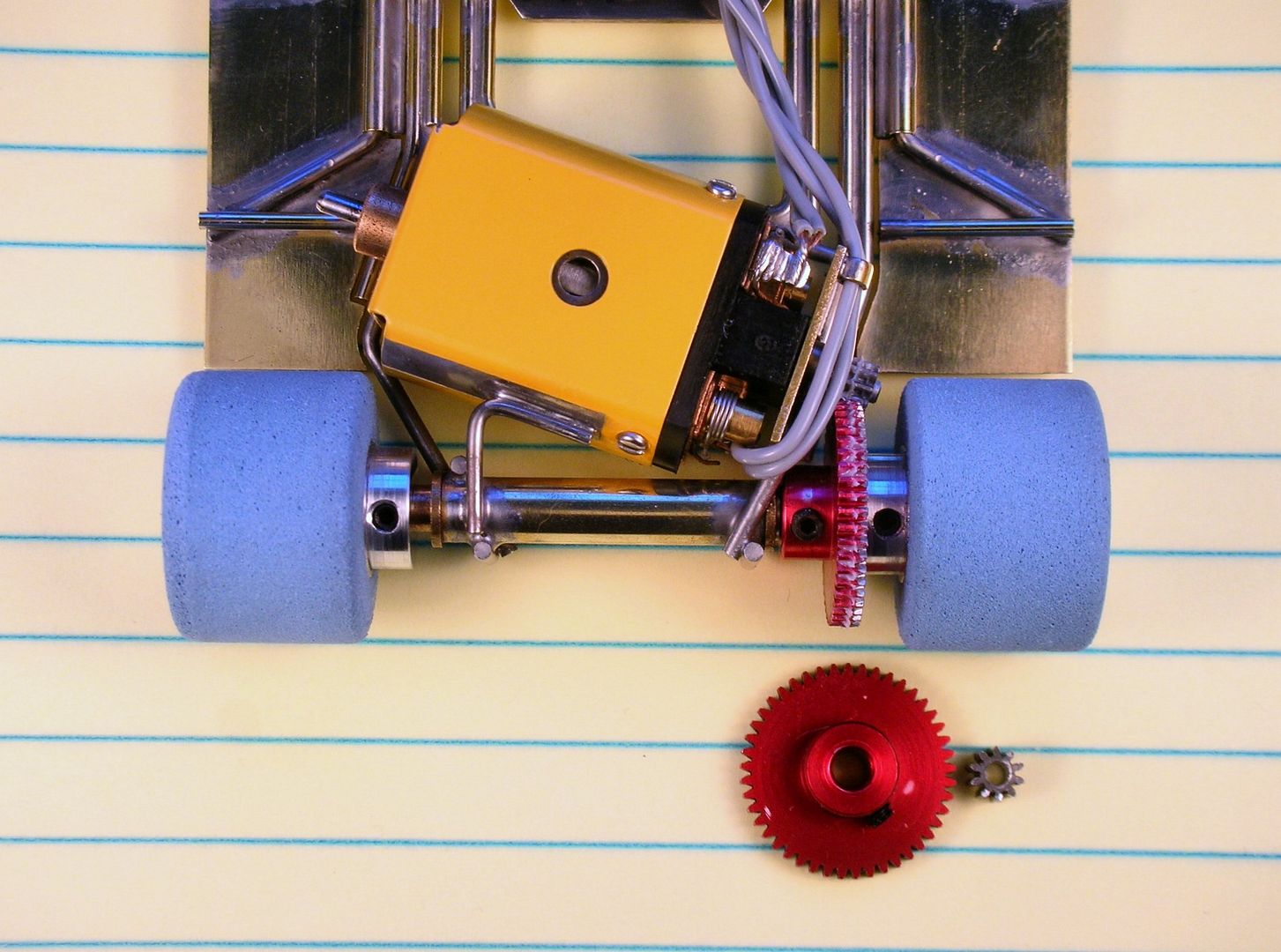

Based on the picture of Howie's and other cars from his race and the tech chart from a race held a few weeks earlier which lists Weldon and Cox gears only........we went with the Weldon 64P.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#89

Posted 28 July 2016 - 10:59 AM

I love that low slung Lotus 40. Looked great in ,still looks hot 48 years later. Unlike some ladies I knew back then ![]()

Cheers

Bill Botjer

Faster then, wiser now.

The most dangerous form of ignorance is not knowing that you don't know anything!

Never attribute to malice that which is adequately explained by stupidity

#90

Posted 28 July 2016 - 12:49 PM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#91

Posted 15 August 2016 - 06:20 PM

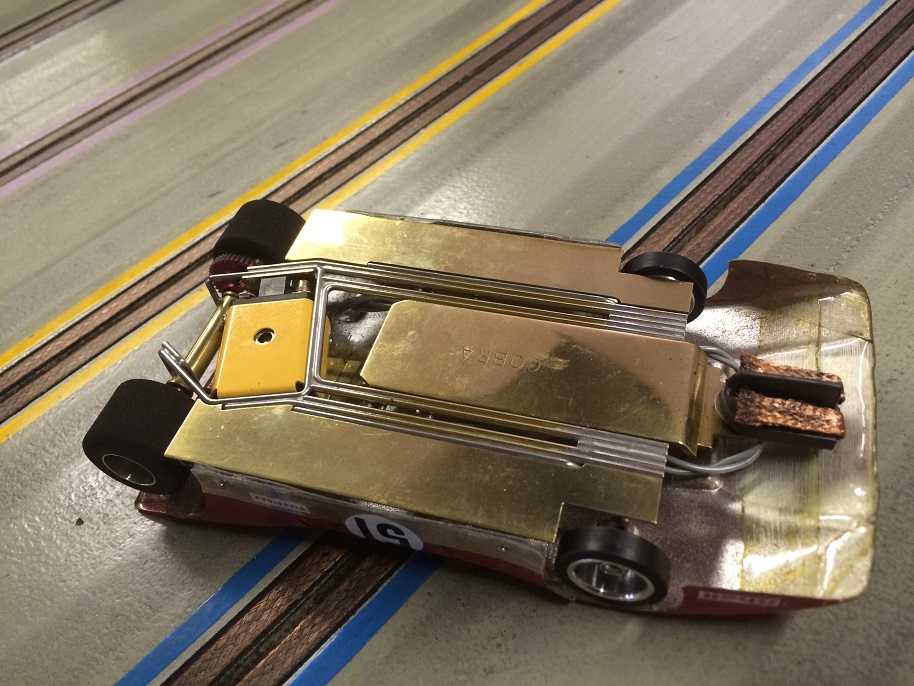

I sent the car off to Rodney for preliminary testing to hopefully work out any bugs before sending it to Howie. Rodney’s first order of business was installing an old body for testing:

Here’s Rodney’s report in the blue italicized test:

Testing at Eddie's

Eric and I arrived at Eddie's Slot Car World before it opened to conduct today's tests.

Everyone including Eddie admired the chassis and motor. Amazing build.

Blue King

I tried it on the Blue King first. The car is a little short on brakes, so the car took some getting used to.

I have found that non-cut up Mura A can motors have lots of mass when compared to the Champion and '68 Mabuchi motors of the day. The mass of the Mura A can in an angle-winder chassis will most likely result in a tail-happy car:

The car handles neutral to a point and when pushed, the car will step out with a slight oversteering hop. It was easy to drive the car fast and smooth below the "hop" limit. If the track had a normal amount of evenly-applied spray glue, the car would not have hopped and would have just slid out a bit more.

Captain Rick Comment here:

About Eddie’s track surface, it has a layer of built up rubber and very little spray glue. It’s the layer of rubber that affords the grip to the cars. This car tailed out more than the modern flexi past this built up rubber causing it to do a “hop”. This was NOT “chatter” in the traditional sense and, as Rodney said, should not be a problem on a “normal” spray glued track.

The track had so little spray glue that I was wearing out the tires at a quick rate. You could see the large amount of tire rubber build up on the top of the chassis.

The motor does not hit full acceleration or start to "jet" until about a third of the way down the main straight. I clutch for the bank turn and power out of the bank. On the short straights, the car lacks some grunt. I would wait for the car to spool up and have to brake early for the turns. So the car would lose time on the short straights.

Eric and I think the Mura "can in a can" magnet set up with the Versitec magnets are not matched to the 70's era 27/28 double wound armature in the car. This may result in the lack of brakes. Champion blue dot magnets and a Champion shim may help.

The gear ratio is already 4.5 to 1, so running an even lower gear ratio to get better brakes and acceleration would not be period correct.

The best lap time on the Blue King is shown:

Road Course

I then tried the car on the road course. First, this is not a road course car. These types of cars are designed for a swoopy track. Anyway, the car does oversteer in every turn, and I had to carefully judge the braking point to turn the lap time shown:

Conclusion

The track test results and analysis may sound a little harsh. In reality, the track tests describe how an early anglewinder era slot car drives. Anglewinder cars did evolve to use lighter weight motors. Also remember, our track tests are conducted with very low spray glue conditions and with modern tires. The car would run better with blue or orange tires and lots of tire glue. It was fun to drive this period of slot car. It reminds me of my 1 to 1 scale 1972 R Gruppe 911. A car with an edge to it:

Thanks, Steve and Rick, for letting me drive this piece of slot car art.

Thanks Rodney and Eric for your help and input. Next up, I hope Noose will work his magic on the Lotus 40 body! ![]()

- Jencar17 and Tex like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#92

Posted 19 August 2016 - 04:51 PM

Based on Rodney's test, I decided to change the gearing from 10/45 (4.5:1) to 9/46 (5.1:1). The total tooth count of the gear sets remains the same at 55 teeth so the center to center distance between them is virtually the same........no need to unsolder the motor (the old gear set is on the bottom):

The new 46T spur gear is only .748" in diameter so there are no track clearance problems with the .875" tires.

- slotbaker and Jencar17 like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#93

Posted 19 August 2016 - 06:15 PM

Interesting. I didn't know that having the same number of total teeth kept the distance (mesh) the same.

Don

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#94

Posted 19 August 2016 - 06:24 PM

Neither did I. It pays to watch the Masters ![]()

Paul Wolcott

#95

Posted 19 August 2016 - 07:46 PM

..........I didn't know that having the same number of total teeth kept the distance (mesh) the same.

I didn't either until I was trying to find some gears that would work with a sidewinder Pittman project car. Here's the center to center distance formula I found:

C = (N1 + N2) / 2P

The number of teeth of the pinion (10) and spur (45) gear are added together. Then that is divided by twice the pitch which on these gears is 64.

.4296" = (10 + 45) / 128

So I found that it doesn't matter how many teeth are on which gear....just what the total number of teeth is.

- gc4895 likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#96

Posted 19 August 2016 - 09:58 PM

Interesting. I didn't know that having the same number of total teeth kept the distance (mesh) the same.

Don

"...virtually the same..."

I know, it's a fine distinction, but gear mesh with a motor of power is a critical factor. I hadn't heard this before either; I'll have to try it out and see how close "virtually" is.

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#97

Posted 19 August 2016 - 10:54 PM

When you try it out, remember that the gear manufactures must be the same. There is a tolerance in everything.

- Tex and tonyp like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#98

Posted 20 August 2016 - 08:30 AM

When you try it out, remember that the gear manufactures must be the same. There is a tolerance in everything.

Little gold nuggets just keep popping up in the sifter....

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.

#99

Posted 20 August 2016 - 10:26 AM

Here's another one on the gear subject Tex:

Different manufacturer's gears sometimes have different "tooth forms" within the same "pitch" size......which seems to mean (kinda - sorta) the shape of the teeth can be slightly different. In this build I'm using Sonic 64P steel pinions which visually match up with vintage Weldon pinions and work with the vintage Weldon spurs gears beautifully.

I've had many problems finding "the right" pinion gear to mesh with Cobra spur gears and Weldon crown gears. With a magnifying glass you car really see the different shapes between some gears............

Anyway, this is just my observation and your results may vary. ![]()

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#100

Posted 20 August 2016 - 01:06 PM

I hear ya and have NO reason to doubt you, Rick. But I'm just plain too lazy to put that much effort into it. I guess I am self-relegating myself to mid-pack status. LOL

EDIT: I left the work "NO" out! Sorry... didn't mean to give the wrong impression! LOL

- tonyp likes this

Remember, two wrongs don't make a right... but three lefts do! Only you're a block over and a block behind.