Because a lot of the tech details are buried in this rather lengthy thread, I thought I would put the math used to calculate corner circumference and radius here.

First thing is you need to make an accurate scale drawing of your track. Mark all the corner diameters and the degree of the corner on the drawing.

Figure out your circumference by multiplying pi times the diameter of curve in inches. This gives the circumference of a full 360 degree circle in inches. Divide the full circle in inches by 360=length of 1 degree in inches. Multiply that by the amount of degrees of the corner and that gives you the corner circumference. So pi times D is divided by 360 and then multiplied by corner degrees=corner circumference.

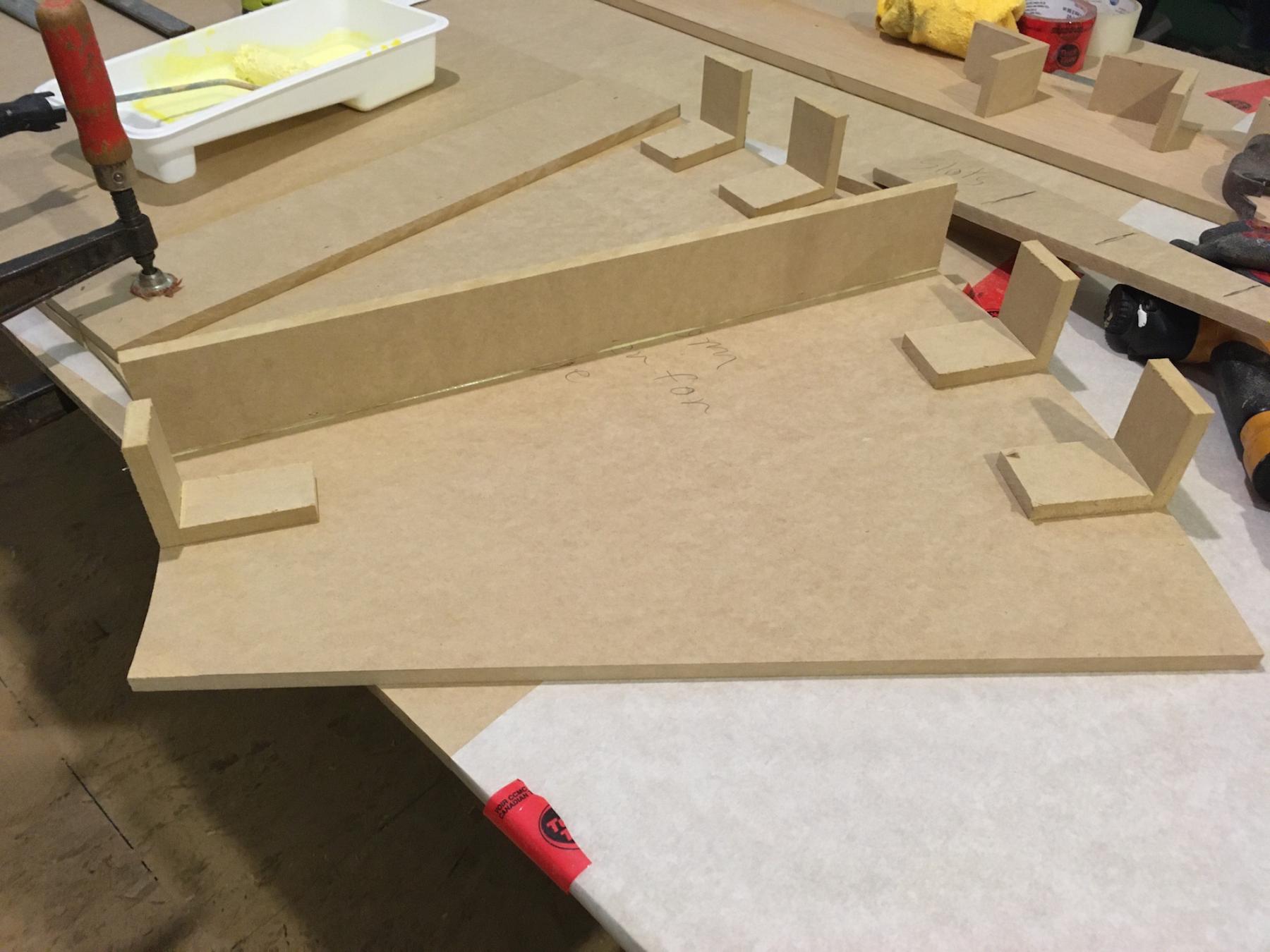

The cut circumference of a corner is the SAME whether the corner is flat or banked. A corner gets banked because it's radius has been increased, nothing else changes.

So radius of a bank turn is as drawn radius of turn divided by the cosine of the degrees of banking=radius the turn must be cut at. You have an 8 foot diameter turn you want to bank at 10 degrees the radius is cut at 48.74". Since it isnt that critical I would just call that 48 3/4".

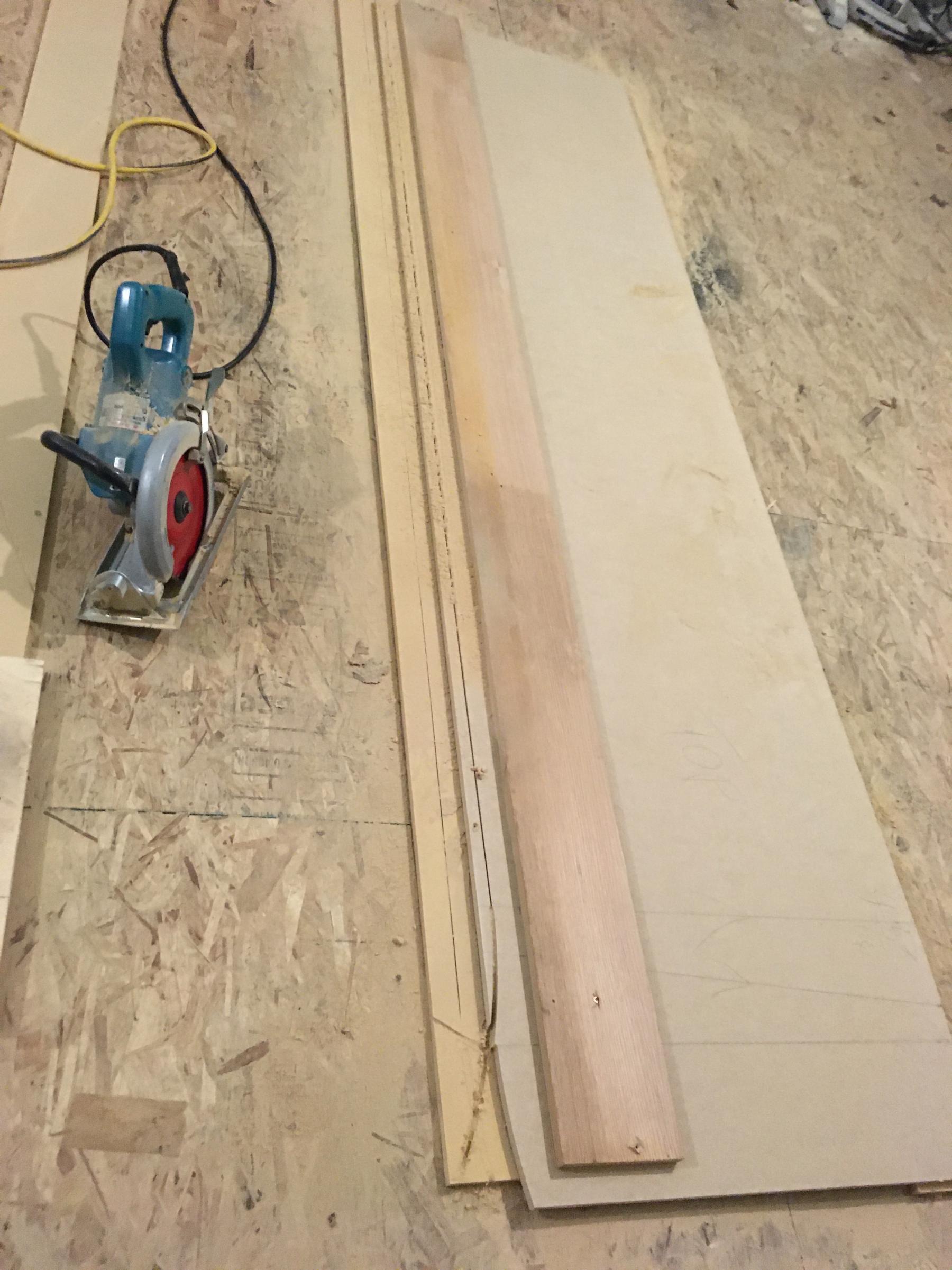

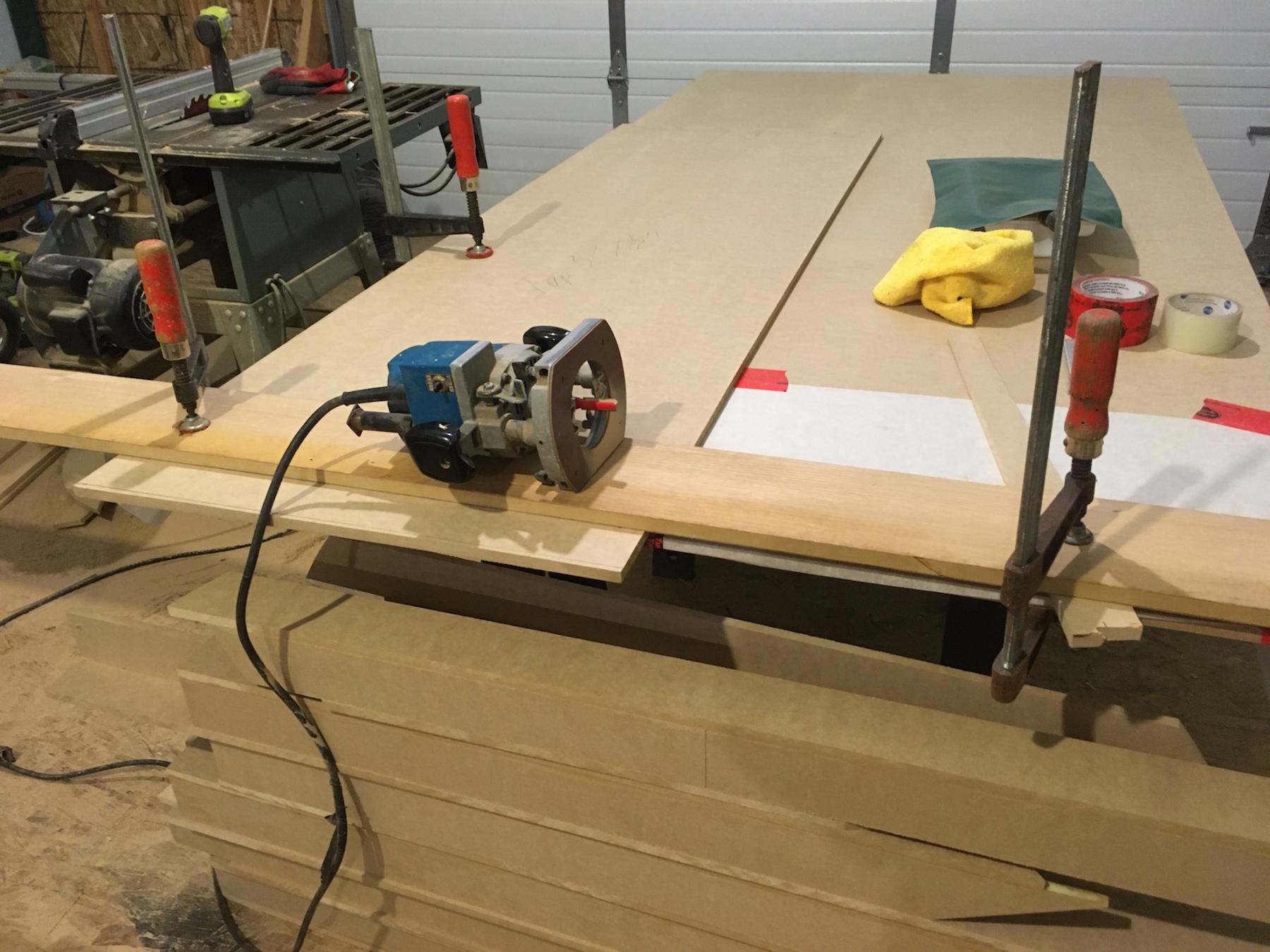

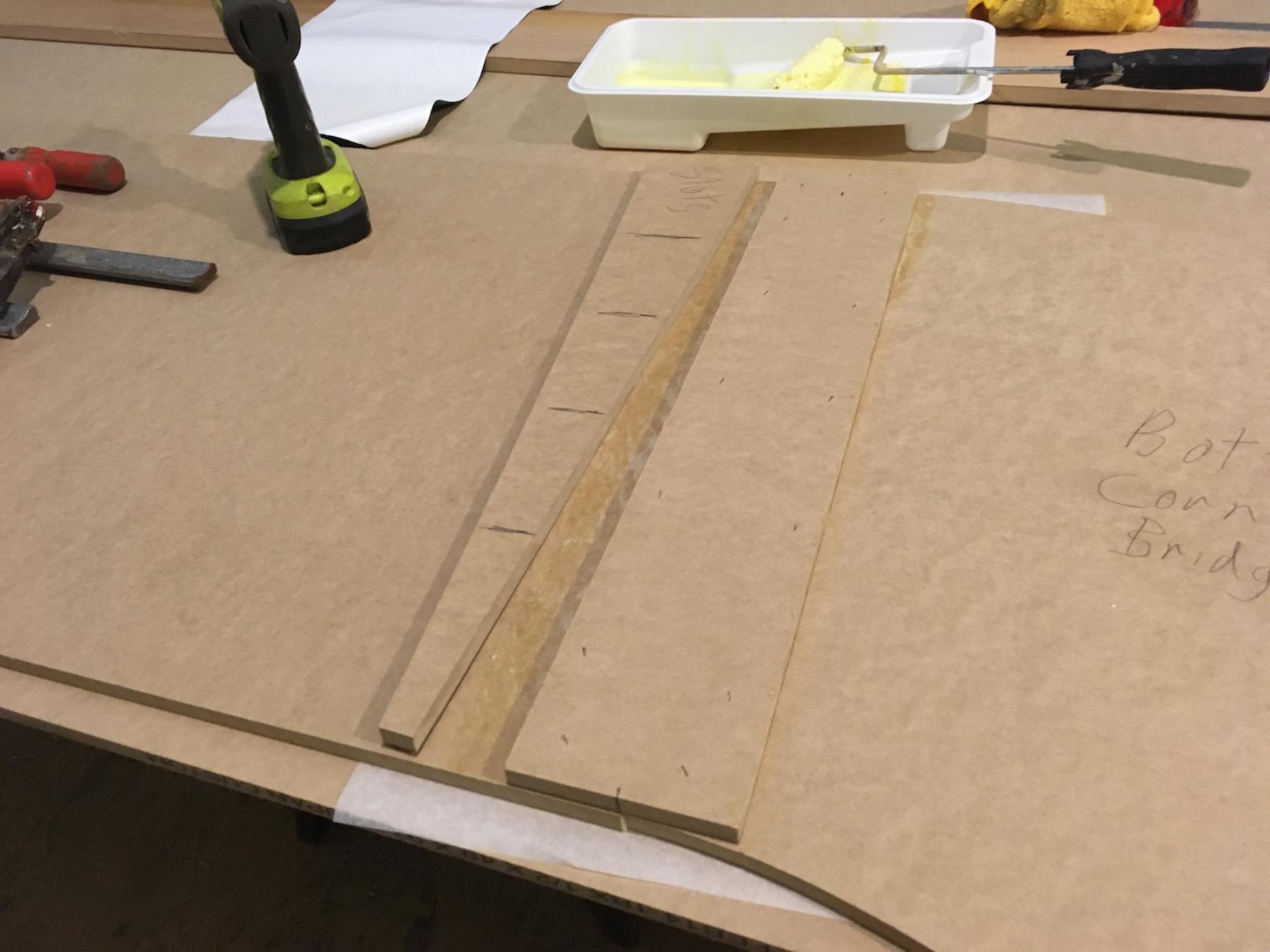

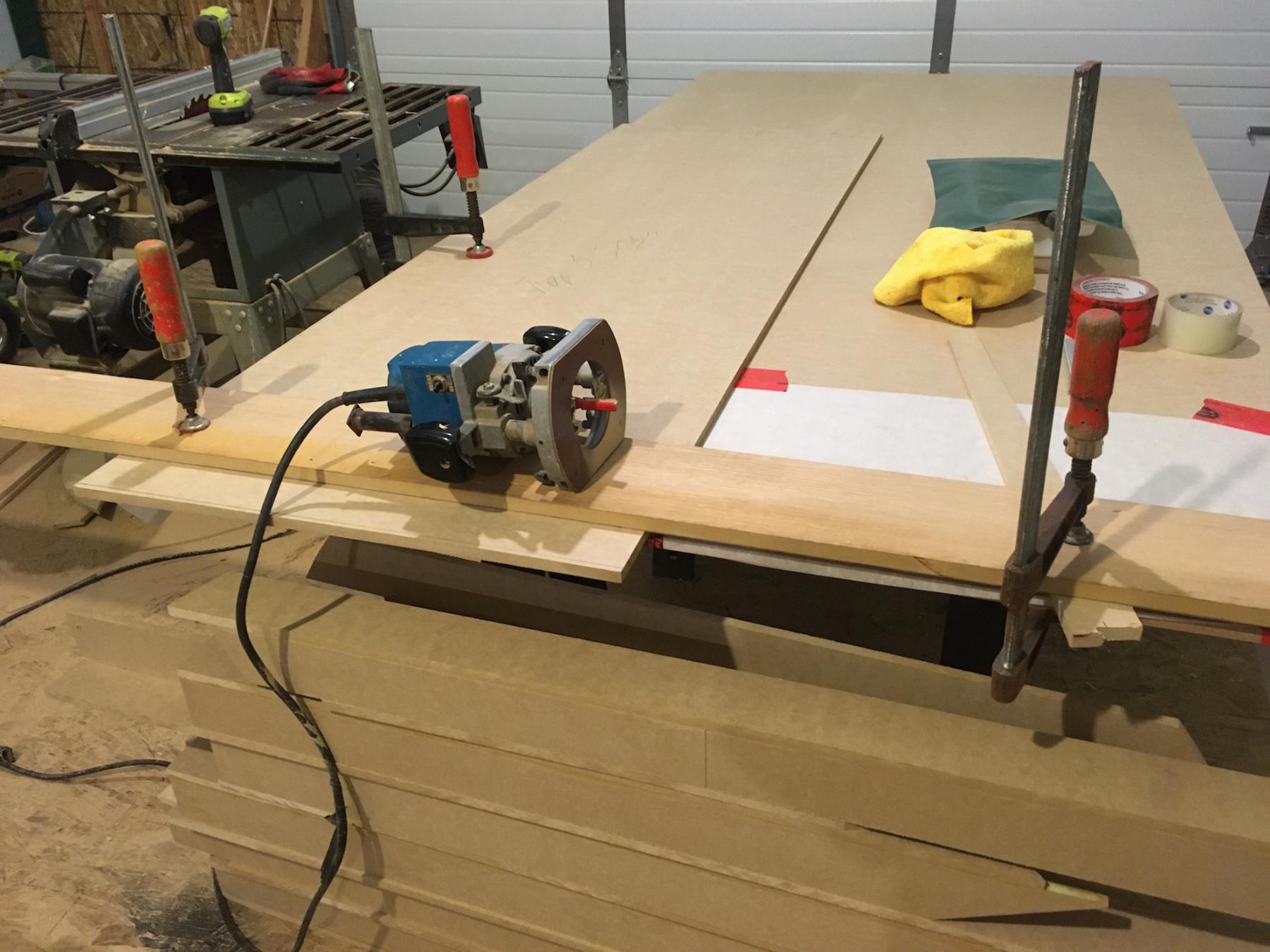

The dimension that is critical is the circumference. Get a 1/2 or 5/8" wide tape in the longest you can find to measure circumference. I use red tuck tape to hold the tape in place because it is nice and sticky. After a while it will destroy the tape measure. This tape is on for reference only. A 1" tape will not go around an 8 foot diameter curve without buckling.

An easy way to convert decimals to fractions without using a calculator:

Just open it till your decimal is up on the display and then measure it with a tape. Mostly I try to work to a 32nd but realistically it is wood marked with a pencil so if you are within a 1/16 you are doing pretty well.