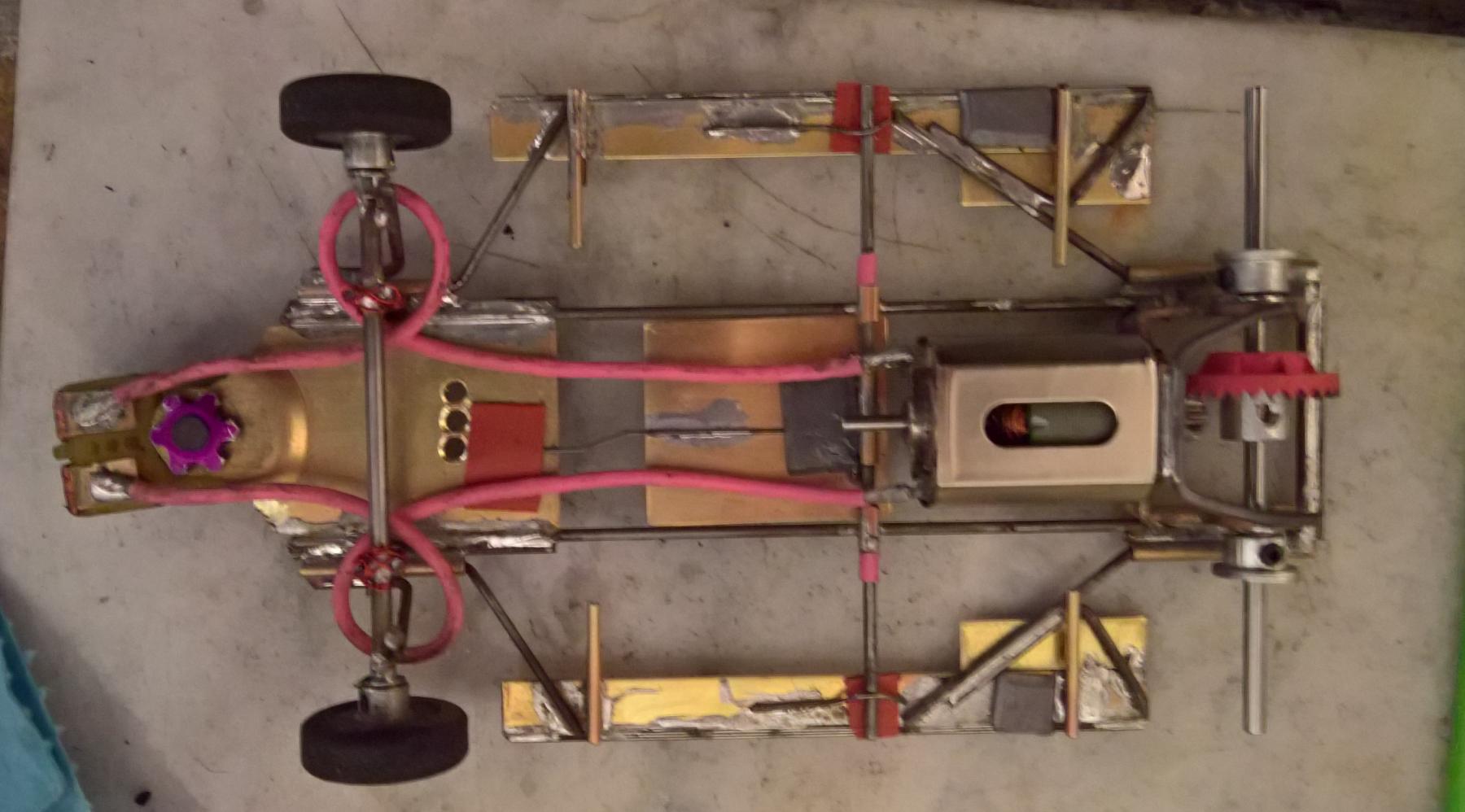

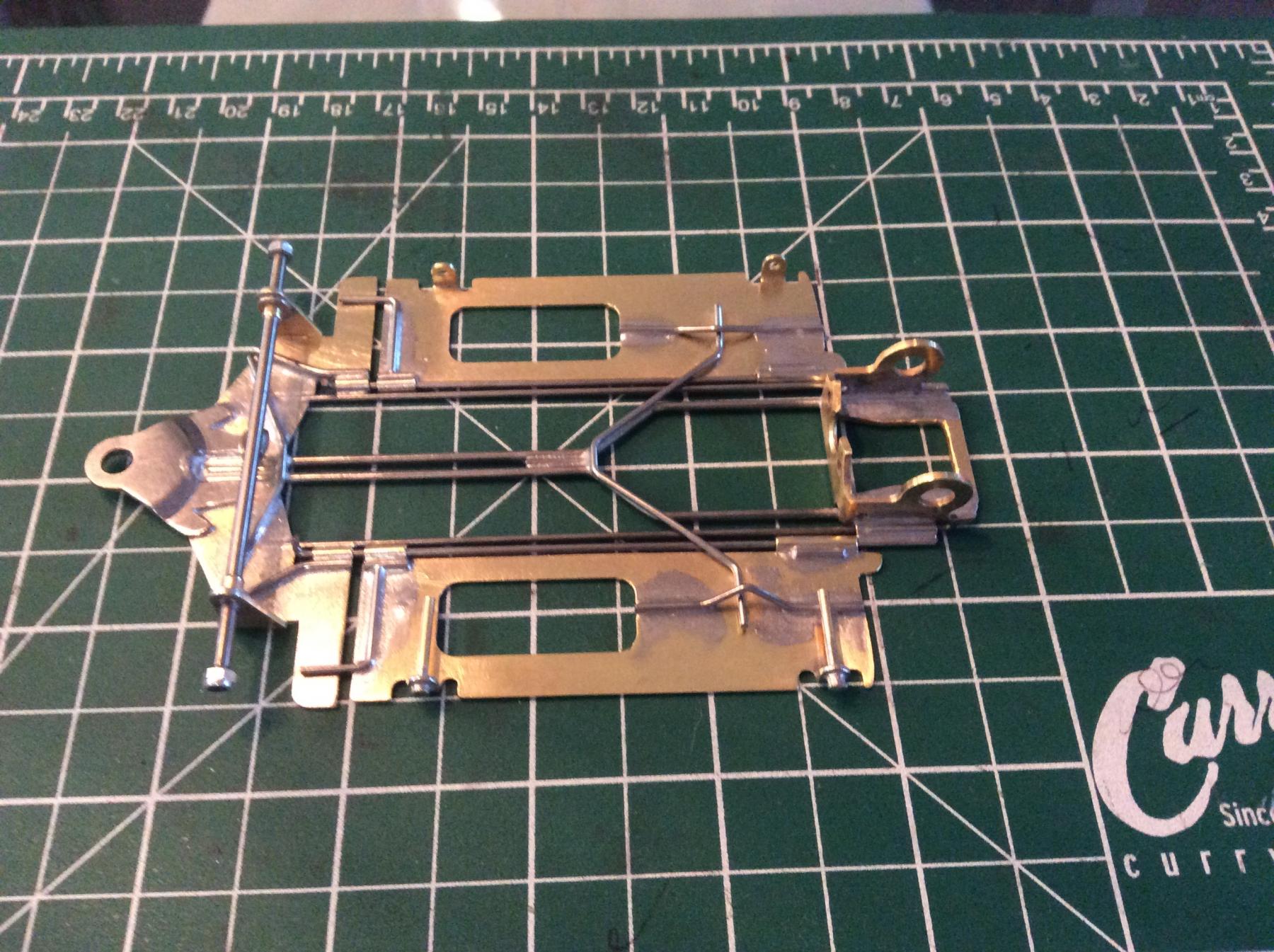

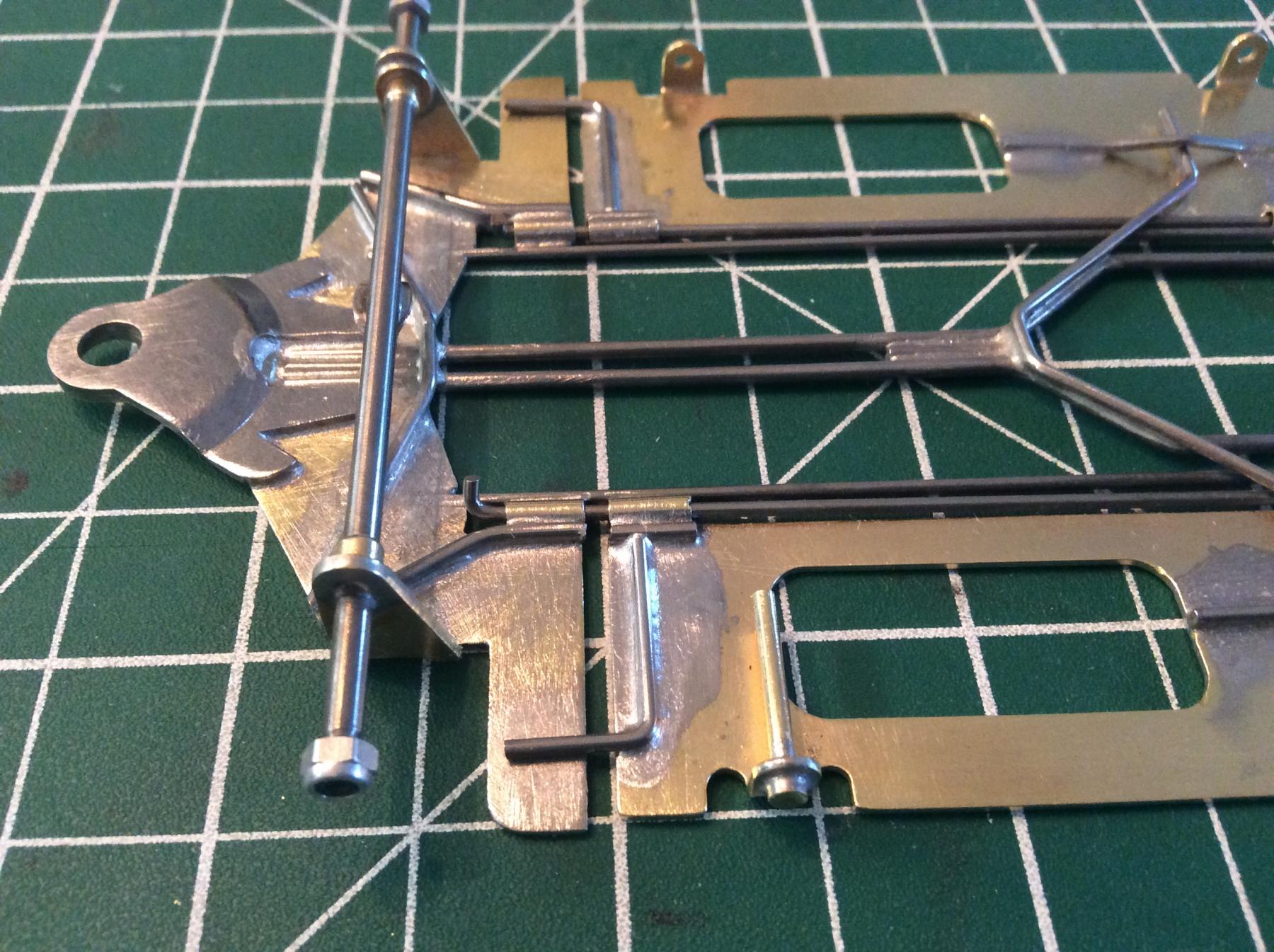

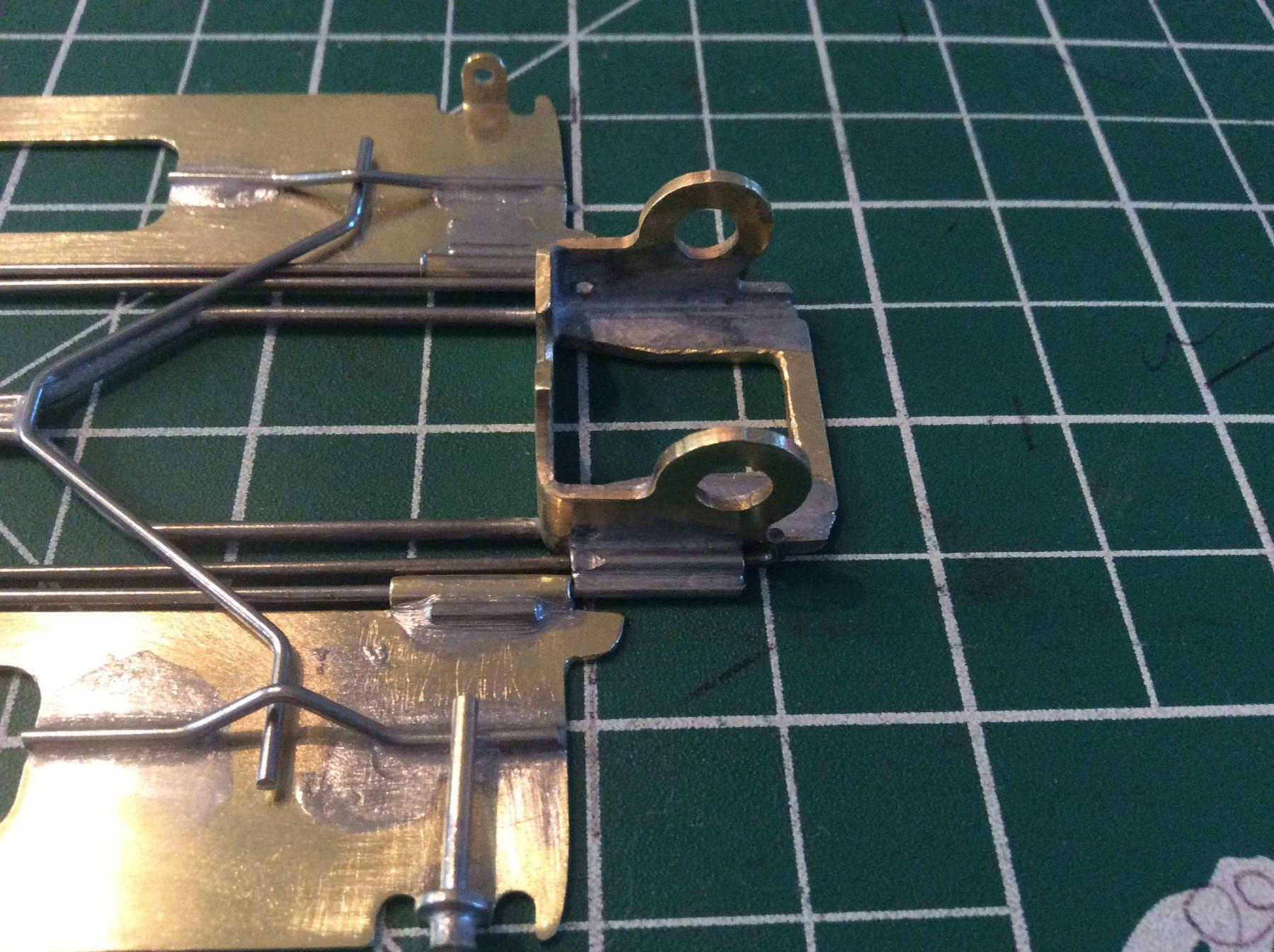

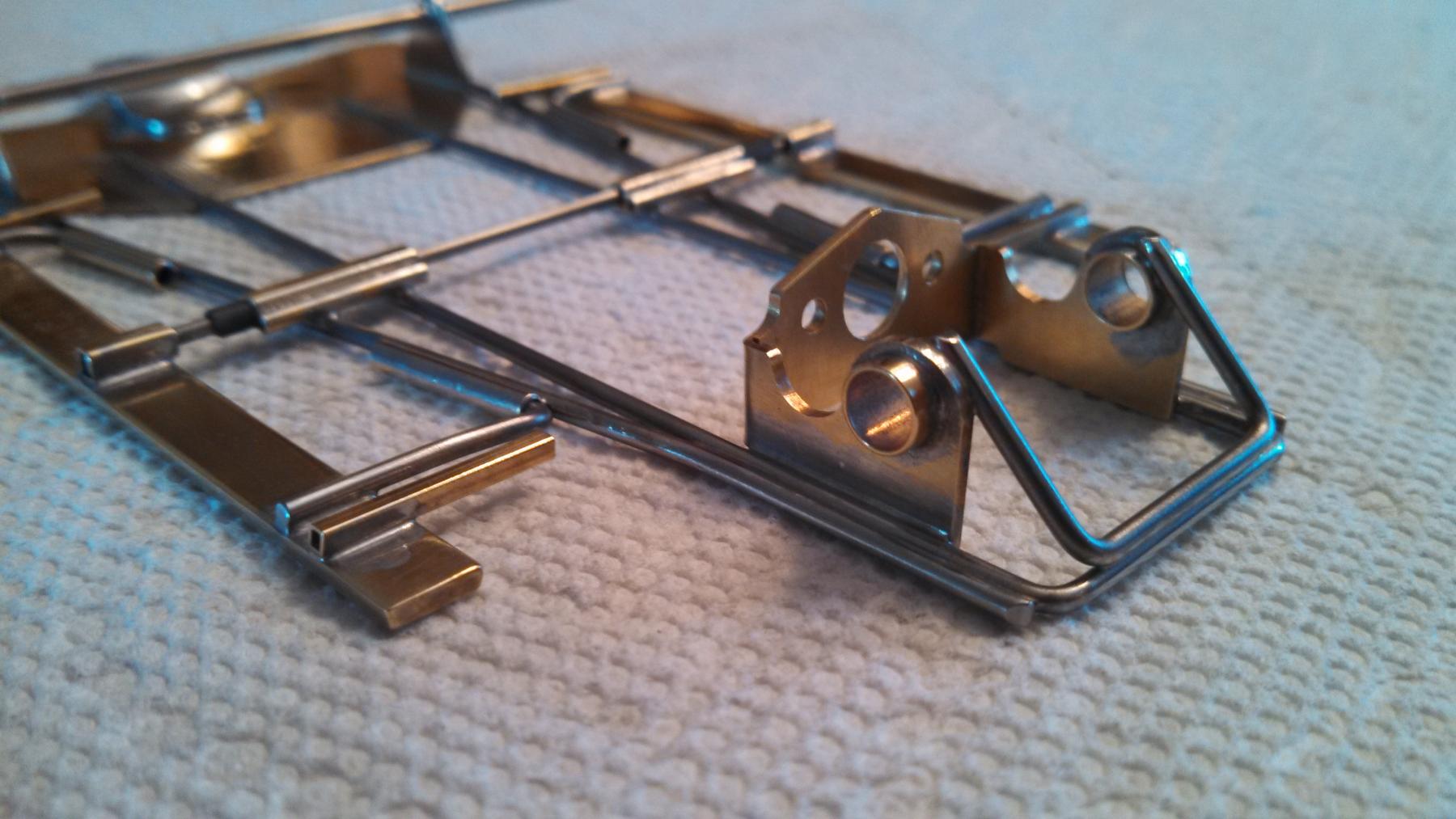

Trevor, that is great work in general, and would say it is amazing to see that qualify of work on your first retro build. I like just about everything I see going on there, there is one area I offer a suggestion with. It looks like you are using .047 wire in a piece of 1/8 square tubing to control pan movement - this is way, way more movement than you'll want to use in a car. Getting pan movement up/down to be in a range of .025 or less is pretty much the direction to go in

James,

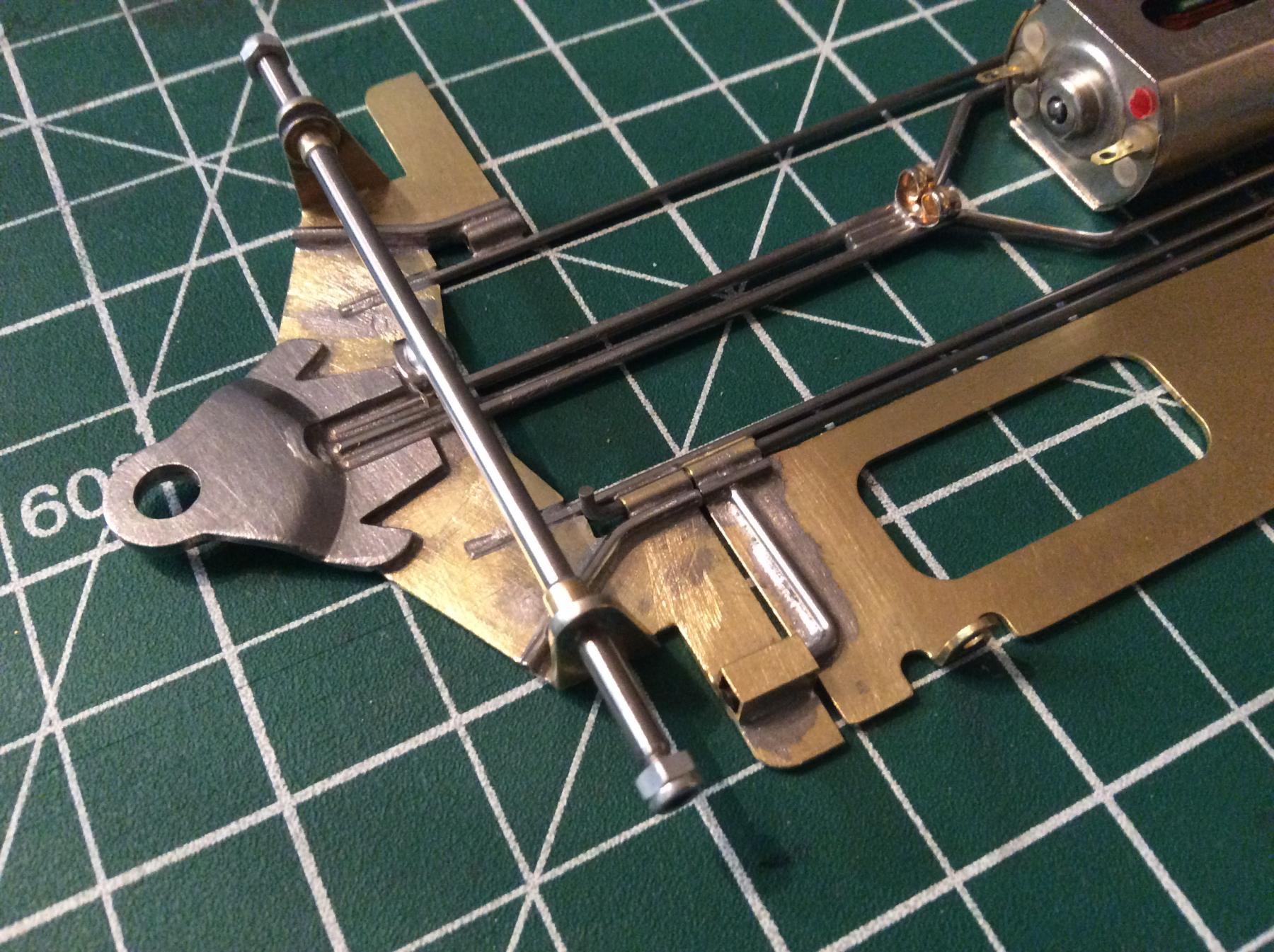

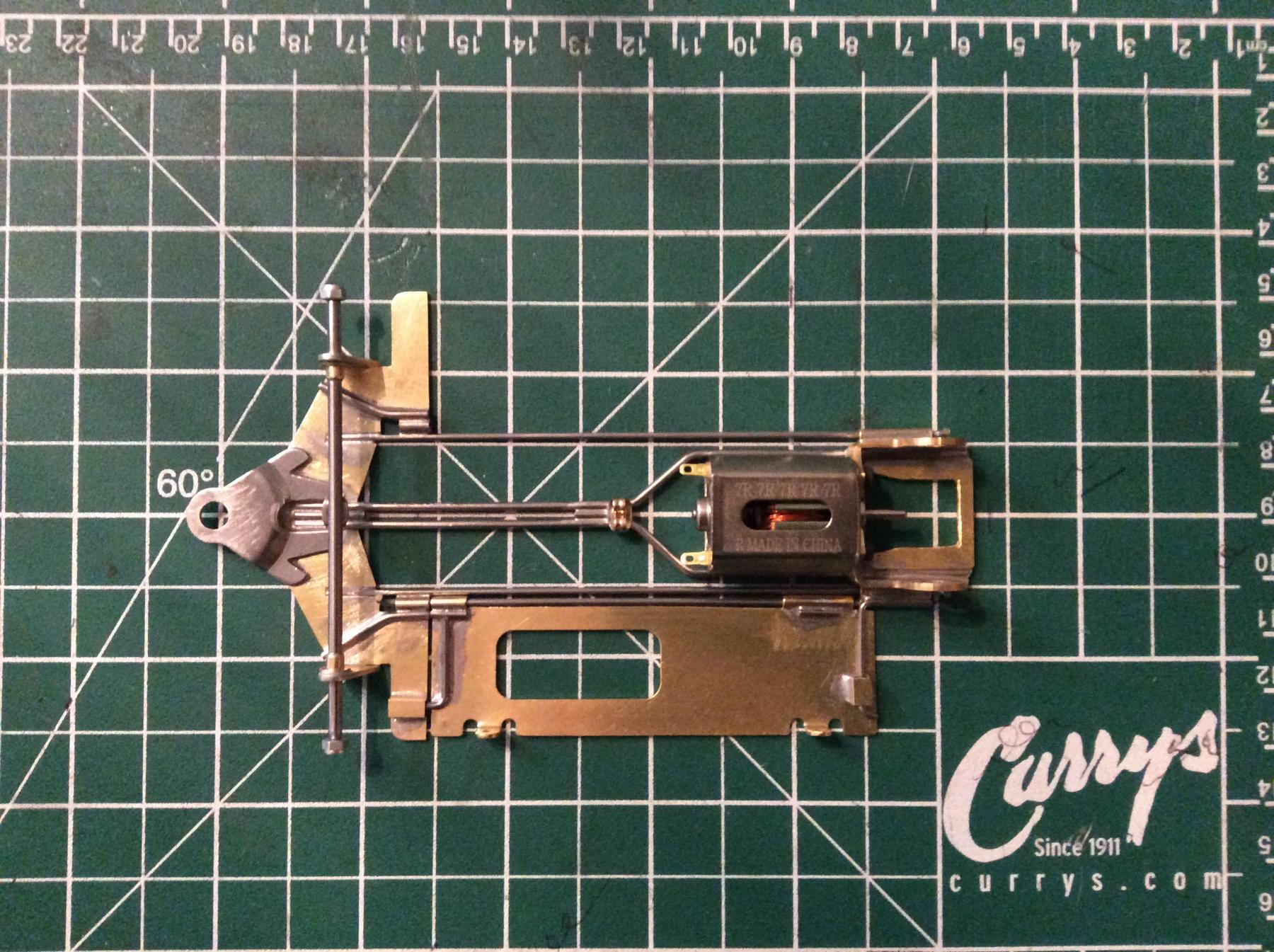

The tubing ID is .065 and the wire OD is .047 so it has .018 of range in the hinge, the rear is fixed so its limited to .018 of movement with the front being the floated portion the range is .036 at its maximum. The average range of movement would be .027 for the pans "shake".

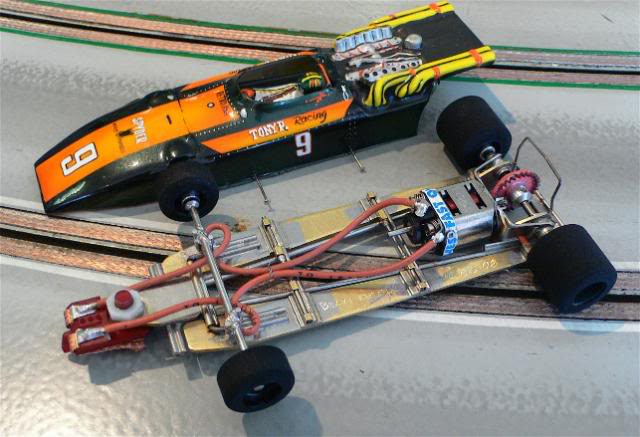

As for weight placement, do you know off hand the balance point of the cars you have used at Tom Thumb? If you could find the balance point and then measure from the rear axle to the balance point for me that would be great. If you could also share with me the wheel base and guide lead of the cars you have had success with at Tom Thumb.

Dominic,

Do you prefer the stiff car with the lower power motor so you can run a softer tire and get the bite out of the car? My thiught process was a softer car would bring up the bite allowing a firmer tire or narrower tire. With the limited power motors i was hoping that by reducing the tire drag would create some additional speed in the chutes and straights.

Andrew,

Thank you very much, I have enjoyed following the progression of the cars you have been posting. I like that your always thinking and trying new ideas. Keep up the good work!

Cheers,

Trevor