Don, that chassis looks interesting... If Brian designed it, It will work!

Lookin' good Raisin!!!

Posted 25 May 2013 - 07:24 AM

Don, that chassis looks interesting... If Brian designed it, It will work!

Lookin' good Raisin!!!

Posted 25 May 2013 - 04:00 PM

Great job Raisin, chassis looks killer!

A motor is only as fast as the chassis it's in.

Dominic Luongo

Like Dominator Custom Chassis on Facebook

NERR photos from 2012-April 2016

NERR photos from 2016 to now

Posted 26 May 2013 - 07:32 AM

Nice work Mike. What size wire on the rails?

Thanks John, the rails are .047

Raisin

Posted 26 May 2013 - 07:36 AM

Hi Raisin,

Did you run that chassis in Can Am at the Demon 500? If so, it looked like it was working really well for you.

No Terry, this one wasnt completed when I ran at the Demon 500. I used a JK X25 from Mike Swiss at Chicagoland Raceway

Thanks

Raisin

Posted 26 May 2013 - 07:38 AM

Thanks for the positive comments Rick, Slotstox#53, Macman, and Dominator

Raisin

Posted 03 June 2013 - 04:49 AM

Just scrubbed and already needing a trim around the pintubes: Duffy #79 Danse Fambeau, concept tester for a bevy of GTC sleds.

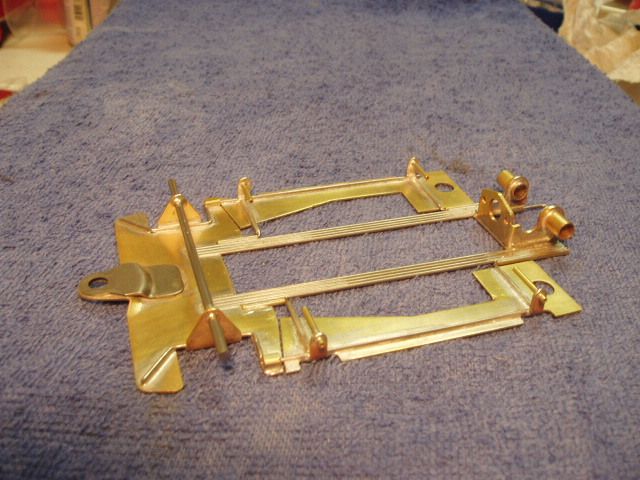

This continues the "Forward Flex" idea we've been playing with, reinforcing the rails to motor front face & limiting flex moment to like 2.5" to front mass. Rails .047" & .040" brass, tipping 57gr before shaping the bracket.

See what happens.

Duf

Posted 03 June 2013 - 06:31 AM

Paul Wolcott

Posted 03 June 2013 - 07:02 AM

Being new to this I am noticing a trend to move the weight more toward the rear of the chassis. Do you find that you need a less bitey tire with this design?

Nice work

Raisin

Posted 03 June 2013 - 02:10 PM

Being new to this I am noticing a trend to move the weight more toward the rear of the chassis. Do you find that you need a less bitey tire with this design?

Nice work

Raisin

Um, not as simple as just that, but it's more 'splaining than this thread's for. I talk in some detail about my own stumbling efforts to get a sense of this stuff in the build threads you'll find in "Duffy's Digs" in Scratchbuilding, & for the mass-distribution thing you'd be mainly interested in the OXCART thread.

A guy I admire a lot and take copious notes from is Dennis Samson, and he talks about his evolution in The RETRO Progression - well worth reading; he explains the rearward mass distribution better than anybody, but I can't find just where he did! Dennis, Haaalp?

Duf

Posted 03 June 2013 - 03:11 PM

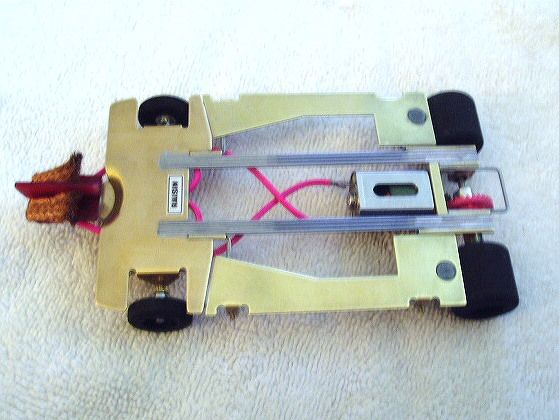

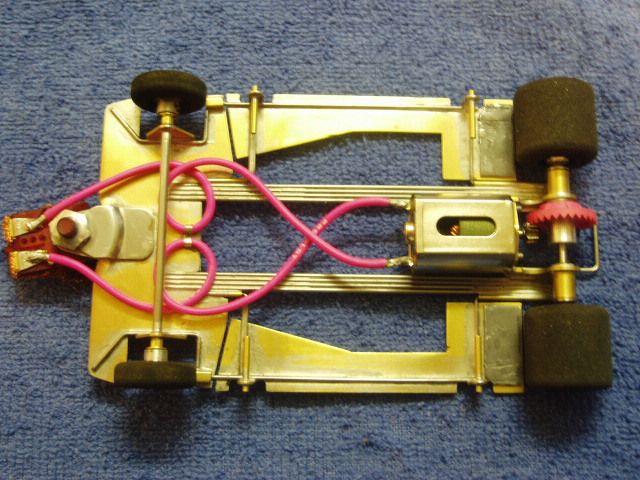

My second build.....................8 rails of .047, JK nosepiece, RGEO pans, and an angled rear bracket from Mike Swiss. This one came in at 107 grams complete with the body and 4 grams of lead on the rear of the pans.

First test was very promising as it ran .08 seconds better than my fastest car to date on our local track.

Thanks for looking,

Raisin

Posted 03 June 2013 - 04:26 PM

Being new to this I am noticing a trend to move the weight more toward the rear of the chassis. Do you find that you need a less bitey tire with this design?

Nice work

Raisin

Raisin,

Been meaning to answer this one.

When Retro started up, it surprised me a bit, too, when I started seeing weight in the back of the chassis

in some of the early designs coming out of So-Cal.

Not entirely, as by that time, I was already a track owner and getting familiar with scale cars that sometimes had lead added

to the back of the pans, which was totally counter-intuitive to me, as a long time wing racer, where you always tried to reduce the

weight in the back.

When we did our weekly Retro racing almost entirely on the flat track, I did witness guys, mostly ex-wing racers, ruin chassis they bought from me,

by cutting out the back area of the pans. (or certainly hurt the flat track performance).

While it seems that weight in the back is usually a good thing , there does seem to be designs that run fine, without it, like the recent

tri-pod chassis that you got from me, that Ray Duran has had much recent success with, and others, also have had, with that same

basic design. So go figure.

So when we talk, now you know why I'm a little wishy-washy on giving out definitive advice.

So for all my slot car experience, about all I can say, with 100% conviction, is:

"You gotta try it and see". ![]()

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 03 June 2013 - 04:51 PM

Posted 03 June 2013 - 04:53 PM

Raisin,

Been meaning to answer this one.

When Retro started up, it surprised me a bit, too, when I started seeing weight in the back of the chassis

in some of the early designs coming out of So-Cal.

Not entirely, as by that time, I was already a track owner and getting familiar with scale cars that sometimes had lead added

to the back of the pans, which was totally counter-intuitive to me, as a long time wing racer, where you always tried to reduce the

weight in the back.

When we did our weekly Retro racing almost entirely on the flat track, I did witness guys, mostly ex-wing racers, ruin chassis they bought from me,

by cutting out the back area of the pans. (or certainly hurt the flat track performance).

While it seems that weight in the back is usually a good thing , there does seem to be designs that run fine, without it, like the recent

tri-pod chassis that you got from me, that Ray Duran has had much recent success with, and others, also have had, with that same

basic design. So go figure.

So when we talk, now you know why I'm a little wishy-washy on giving out definitive advice.

So for all my slot car experience, about all I can say, with 100% conviction, is:

"You gotta try it and see".

Mike, would the position of the motor on an angle winder increase the weight on the rear axle versus having an inline set up where the mass of the motor is shifted forward?

Eric Balicki

Posted 03 June 2013 - 04:57 PM

My second build.....................8 rails of .047, JK nosepiece, RGEO pans, and an angled rear bracket from Mike Swiss. This one came in at 107 grams complete with the body and 4 grams of lead on the rear of the pans.

First test was very promising as it ran .008 seconds better than my fastest car to date on our local track.

Thanks for looking,

Raisin

I almost forgot.

Looks great, but those axle tubes hanging out in mid-air is an accident waiting to happen.

You really need to rig up something like on the first chassis I sent you, which had these;

http://slotblog.net/...xle-tube-brace/

Doesn't need to be those.

Just anything, anywhere, on those tubes, will help.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 03 June 2013 - 05:49 PM

I almost forgot.

Looks great, but those axle tubes hanging out in mid-air is an accident waiting to happen.

You really need to rig up something like on the first chassis I sent you, which had these;

http://slotblog.net/...xle-tube-brace/

Doesn't need to be those.

Just anything, anywhere, on those tubes, will help.

Although it doesnt show in the pics each tube is braced from underneath. That being said I am second guessing myself about running such a wide tube. Now I'm starting to think I like a narrower tube with axle collars so you dont have to reset the gear mesh each time you change tires.

Raisin

Posted 03 June 2013 - 05:57 PM

When Retro started up, it surprised me a bit, too, when I started seeing weight in the back of the chassis in some of the early designs coming out of So-Cal.

This past hour, I've been raking all over for the two perfect paragraphs that Dennis Samson did on rear weight bias; and I can't do it anymore.

Here's how tonyp hipped me to the concept a couple years ago, just as I was beginning my OXCART experiments, starting out with a locked-down bombproof chassis and adding one motion at a time (while watching whatever broke along the way and removing it!)...

The deal is, in a turn, the outside rear tyre is gonna load down, and "squat" a little. They all will, hard tyre or soft, you'll end up on a cant back there. And when that outer rear squats, the outer front becomes the fulcrum for lifting the front up, and the guide starts to pull out just as you're pushing it in toward the inner side of the slot, & there you go nose-first. (Body mounting gets into this too, but that's making it too hard right now. Think about it later.)

So what you do, you "PRE-Squat" the car. Add lead to the rear, lighten the front.

This isn't actually pre-squatting so much as loading the rear tyres so that the mass distribution toward the outside in a turn isn't as great a ratio as it would be with less mass in the rear, but you can visualize as you like.

George Blaha came up with a proportion a while back that we played with, trying to balance the car at a position 71.5% of the distance rearward from guide post to rear axle. The closer we got to that number, the more predictable the car would get, swinging out nicely in turns and not popping out in front, & then we could mess with tyres until we got as good as.

That make sense?

Now, in this way, wing car technology doesn't translate: in Retro you got front tyres, way less downforce, and you got no glue. The dynamic in a wing car is entirely different, and when you're running in a track that would make an Oregon slug blush, of course you can forget about the rear tyres ever coming off and go load the front up! Not the same in Retro.

Duf

Posted 03 June 2013 - 06:11 PM

Duffy looking good, that motor bracket looks bulletproof

That's another thing I was covering in the thread I sent Raisin looking for - a while back I started to try to analyze all the spots that broke on my cars, & why: bad solder techniques, needless stress risers, extra bits - and to try to address how I could do each better. I'm coming up with solutions that seem to work for meee, maybe not universal ones but good for what I do. F'rinstance I got a weird wire arrangement carrying the front axle that tries to distribute any impacts throughout the surrounding structure. So far I haven't had a failure from it, in some pretty brutal racing. (That just means it hasn't been long enough!)

The bracket's another of those places. My thought there is, adding lots of pieces to strengthen a bracket means lots of places for something to break, and maybe break in a place you won't see - so you break your heart looking for what's gone wrong with your car. My thought is to start out with a hunk of metal I'm confident in, and let it support itself; and then if I wanna remove some mass from the top, I can shave down as I dare.

The other thing I believe in & not all do, I run my bearings right into the bracket and use axle collars outboard of that. I think a drill-blank axle will flex enough over that length to soften an impact back there, and that fixing bearings too close to the wheels creates a stress riser at the bearing or transfers the stress into the tubes & supporting structure.

There was a thread about just this thing a few months back, and good people weighed in on both sides of the argument. Y' choose which way seems right, I guess, then watch how it works for you.

Duf

Posted 03 June 2013 - 06:26 PM

Posted 03 June 2013 - 06:45 PM

Mike, would the position of the motor on an angle winder increase the weight on the rear axle versus having an inline set up where the mass of the motor is shifted forward?

Yes.

It should give you more bite.

I saw a new/future non-Retro oriented item, that did a good job of convincing me.

That's why they took the slot racing world by storm in 1968 (??)

Whether or not in this day and age, with great tracks and tires, if it's that important, who knows ?

Especially in a 1/24th car with .800" wide tires.

I would guess in a 1/32, it would be.

IIRC, I thought someone from out Tom Thumb way, claimed with comparable motors and bodies,

an anglewinder didn't lap any faster on the TT King, than an inline.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 03 June 2013 - 06:55 PM

Posted 03 June 2013 - 06:56 PM

Although it doesnt show in the pics each tube is braced from underneath. That being said I am second guessing myself about running such a wide tube. Now I'm starting to think I like a narrower tube with axle collars so you don't have to reset the gear mesh each time you change tires.

Raisin

I think I now spot the gusseting.

As far as "a narrower tube with axle collars", I agree.

That's why I came out with collars, along with getting a bunch of my pre-cut axle tubes, shortened to a collar friendly length.

And Versa-brackets that don't need tubes.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

Posted 03 June 2013 - 08:50 PM

Raisin, that is why my axle collars are made for direct bearing fitting, just a shim on the bearing and the correct width using a 1" bracket. The correct wheel collars for 3/4" wide brackets has been in the works for months and will be out soon. Stay tuned....

Rick Bennardo

"Professional Tinkerer"

scrgeo@comcast.net

R-Geo Products

LIKE my Facebook page for updates, new releases, and sales: Rgeo Slots...

Lead! The easy equalizer...

Posted 05 June 2013 - 09:58 PM

Craig,

Nice job.

Looks fast with the .750 guide lead.

Is one that short, common at BP ?

Did you have to shorten my collars at all to make legal width?

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559