Scratchbuilt chassis gallery

#1651

Posted 09 June 2013 - 10:33 PM

You could add two outer rail soldered to the front piece, but floating inside tubing soldered to the rear end.. This would make the Frame more rigid without taking away from the flex of the floating fork. Just my thoights

Team R-Geo

#1652

Posted 09 June 2013 - 10:44 PM

Craig, what program did you draw that up in?

"Racing makes heroin addiction look like a vague wish for something salty" - Peter Egan

#1653

Posted 09 June 2013 - 10:57 PM

Yeah--that chassis will be too weak in it's current state--but I"m sure it's just in the "idea" stage with Craig. He'll get some more strength added in there some where. I'd go with .055 side rails-- it won't affect the side flex much if their only attached front and rear--but should add some torsional strength. Looks good--keep drawing!! ![]()

#1654

Posted 09 June 2013 - 11:39 PM

To answer John's question, I've been a draftsman for over 30 years. In 1994 I went to a vocational School to learn AutoCAD and been pounding the keys ever since. So, to answer your question.....I use AutoCAD/Architecture 2013 to produce all of my drawings.

At Mike, thanks for the link. I did read that Jim turned his car into a pretzel at the Cave.

To everyone else, thank you for the suggestions but remember, these drawings are purely conceptual at present. This is my way of working things out virtually without having to do an actual build.

Below you will see one of the ideas I have for keeping the two pieces together. I do like the suggestion of running additional rails but I need to draw it first to see how that design will come together. Stand by!

11/27/57-8/12/22

Requiescat in Pace

#1656

Posted 12 June 2013 - 03:13 PM

Craig:

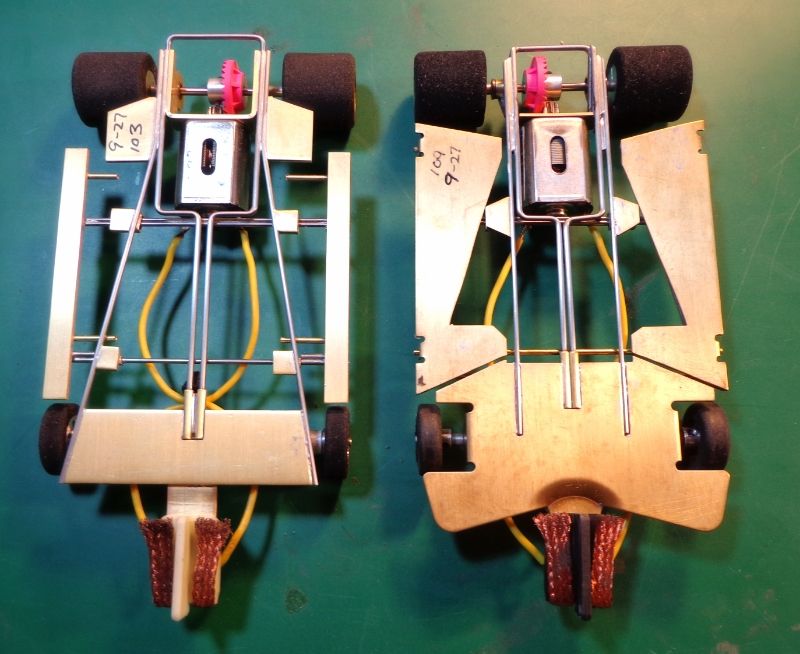

Here are two versions that I have so far.

On the right, is a car I had with me @ the Cave. It was faster there than the car I used to win the race. At the time however, the outside rail was .039 and having just crumpled my "forker" F-1, I was reluctant to use it. Since then, the .039 outer rail has been changed over to 1 X .047 and it still works well on higher speed tracks. Since the changeover, I have not tried it on a technical road course.

In fairness to that first car (F-1), the wall shot that it took would have probably knocked a conventional car out as well. However, that first F-1 was just folded up whereas a more conventional car might only have taken a little bend or a broken solder joint.

On the left is new car that I just finished last night. This one uses an outer rail of .055. This car is noticeably stiffer than the first one but still softer than a conventional 2-rail. I think that I want a little more twist flex than what this one has but.........no laps on it yet so I can't say fersure.

- DCR likes this

#1657

Posted 12 June 2013 - 03:58 PM

Both look great Jim,

I messed around with the nose piece I'll be using for my build and it appears it's going to be somewhat like the one on the right in your picture but with a .925" bracket. The outer rails are going to be .055" on mine as well, I'm not so sure having a little stiffer car for the King is a bad thing. I'll give it a whirl, the worst thing that could happen is it doesn't work. In that case, change it on the next build right?

Thanks for you input!

11/27/57-8/12/22

Requiescat in Pace

#1658

Posted 12 June 2013 - 06:43 PM

Nice Craig & Jim! ![]()

Home of the Gorski Double-Micro Controller

#1659

Posted 12 June 2013 - 08:13 PM

Good stuff guys!

"Racing makes heroin addiction look like a vague wish for something salty" - Peter Egan

#1660

Posted 12 June 2013 - 10:59 PM

This same style F1 uses .040 brass side pans instead of piano wire to help keep the whole thing straight and together. In fact the little tubes at the rear are the ONLY thing keeping it from separating into 2 halves! I have tried it with a little slop at the rear hinge and it works A LOT better with zero play and very tight. At 95 grams it works great on the Buena Park King track and at 115 grams it works great also on the Flat track.

- DCR and Tim Wilkins like this

#1662

Posted 15 June 2013 - 06:13 AM

Nice Don!!!

Jeff Strause

Owner, Strause's Performance Racing (SPR)

USSCA 2016 4" NASCAR Champion & 4 1/2" NASCAR Champion & Retro Can-Am Champion

USSCA 2017 All Around Champion

USSCA 2019 All Around Champion

#1663

Posted 15 June 2013 - 08:07 AM

#1664

Posted 15 June 2013 - 08:07 AM

It looks so good my cell internet decided to post it twice!! Ooops

#1665

Posted 15 June 2013 - 12:41 PM

#10 not only lives but looks really sweet! Excellent looking chassis

It looks so good my cell internet decided to post it twice!! Ooops

Thank you SlotStox for the kind words.This is not my best workmanship,,as I had to build it in a hurry,{and it Shows},and with a huge lack of sleep the last few weeks.These hinged cars a a pain to build,and the hinges are going to wear-out very quickly making the chassis very loose{Loose Hinges},,and not handle well at all.But when there fresh and new they seem nice,so Iv been testing them lately.I am building a more conventional chassis{TonyP/Kamo style} right now for next weeks race..........I just wish I had more time to build,,as these chassis take me 20-30hrs to build with all the hand cutting & fitting,also everyone of my chassis is different then the last,so there is a lot of time in "Designing it on the fly"........Take care,DC

"DCR Slot Cars" on FaceBook

#1666

Posted 15 June 2013 - 12:59 PM

Don:

Really nice work. I built something almost identical in concept about a year ago and it was good but not great. However, I think you nailed something that I missed and I'll bet this works much better than mine did. This inspires me to dig out my old one and "fix it".

Great job and extremely well thought out.

#1667

Posted 15 June 2013 - 01:12 PM

Don:

Really nice work. I built something almost identical in concept about a year ago and it was good but not great. However, I think you nailed something that I missed and I'll bet this works much better than mine did. This inspires me to dig out my old one and "fix it".

Great job and extremely well thought out.

Thank you Jim,,we built cars like this back in 1977-1979,and they had moments of "Greatness" on those old rough tracks,,but when the smoke cleared and the laps where totaled and they just didn't live up to our hopes.It's tough to beat a well built/setup standard chassis in the long run.In my testing of these hinged cars on the BPR king,the hinges need to be retightened in about 2hrs of track time{or less},and maybe replaced in 4-5hrs,and there a HUGE PAIN to replace and most people just couldn't do it......but I guess it's fun to try something old or is it new again?.....Thanks DC

"DCR Slot Cars" on FaceBook

#1668

Posted 15 June 2013 - 01:25 PM

,the hinges need to be retightened in about 2hrs of track time{or less},and maybe replaced in 4-5hrs,and there a HUGE PAIN to replace and most people just couldn't do it......but I guess it's fun to try something old or is it new again?.....Thanks DC

I think there may be an answer for this.....maybe.

IMO, the main advantage is soft torsion that you can't get with conventional rails. The "slop" in the hinges seems unavoidable especially, the more of them you have. However, I think if you tie the front half and back half together with "minor rails" of .032 or the like, you can take out the inherent slop in the hinges yet preserve the flex. I just did this on an F-1 with 4 hinges and it snugged right up. How long will it last????.........dunno.

#1669

Posted 15 June 2013 - 02:01 PM

I think there may be an answer for this.....maybe.

IMO, the main advantage is soft torsion that you can't get with conventional rails. The "slop" in the hinges seems unavoidable especially, the more of them you have. However, I think if you tie the front half and back half together with "minor rails" of .032 or the like, you can take out the inherent slop in the hinges yet preserve the flex. I just did this on an F-1 with 4 hinges and it snugged right up. How long will it last????.........dunno.

As you can see Iv tied both ends together on #10,,,I think it will help???,but I will let you know if it really does.I feel that 4-hinges are just to many in the long run,but who knows???...Im just shooting in the dark,LOL......Thanks DC

"DCR Slot Cars" on FaceBook

#1671

Posted 16 June 2013 - 01:27 PM

GEEZ you'se guys are soldering fools!!! ![]()

![]() Nice builds ALL of them!! And I LOVE the new direction of chassis development--we haven't seen this much done in the last couple of years!! Keep it up---I'll just COPY what works the best!!!

Nice builds ALL of them!! And I LOVE the new direction of chassis development--we haven't seen this much done in the last couple of years!! Keep it up---I'll just COPY what works the best!!! ![]()

![]()

![]()

Damn---I gotta start cutting my own nose pieces now?? Gotta break out the dremels and cut-off discs!! ![]()

#1672

Posted 16 June 2013 - 09:26 PM

#1674

Posted 17 June 2013 - 08:58 AM

#1675

Posted 17 June 2013 - 01:46 PM

Looking good Craig , here's to it being a good performer . Which motor bracket did you use, did you scratch build it?

I had one .925" Warmack bracket left.

I too hope it performs well, I've had my share of cars that were simply so so since I've been back in the hobby. As of late though, everything I've built has been above average and this makes me very happy.

11/27/57-8/12/22

Requiescat in Pace