#2751

Posted 08 April 2011 - 03:16 PM

-john

#2752

Posted 10 April 2011 - 08:19 AM

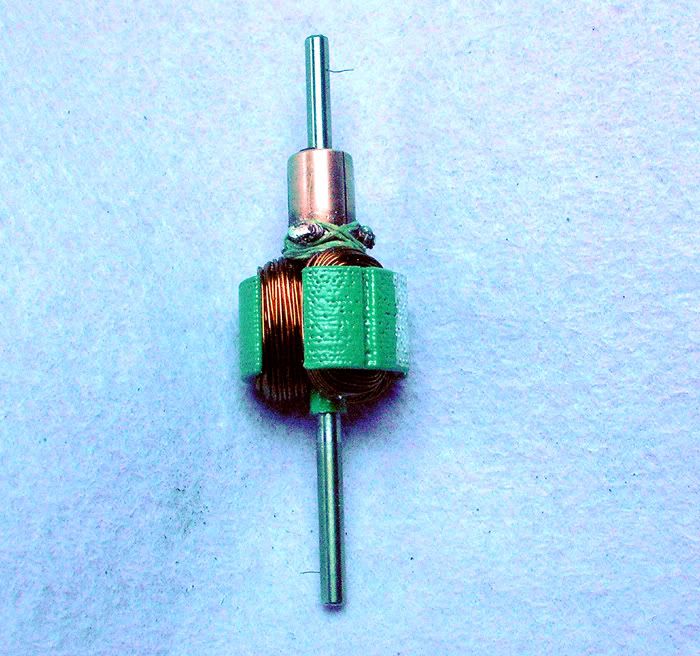

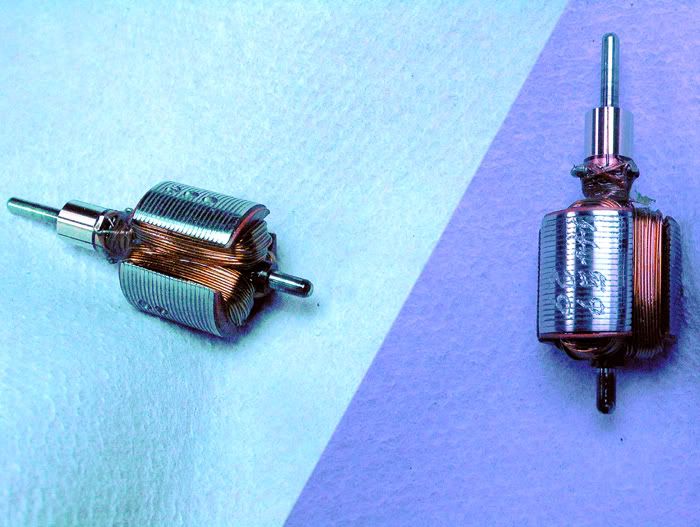

I wound a #28 dbl. on one of Bill Bugenis' eurosport blanks to send him to play with. On such a short arm, it was a tight fit up top near and under the com...but it wasn't that bad. More importantly, I was able to weld the com without any trouble. Even on straight com tabs, a #27 double seems like it would be doable without having too much trouble welding, but I'm not sure how the wind would work under the com height-wise. In any case, a #28 double on such a short stack is a very low resistance arm and should be plenty hot enough. Here's the arm wound, welded and tied. Bill would (as always with the eurosports) do the epoxying, stack grinding, balancing and shaft grinding (if applicable) down to 1.5mm:

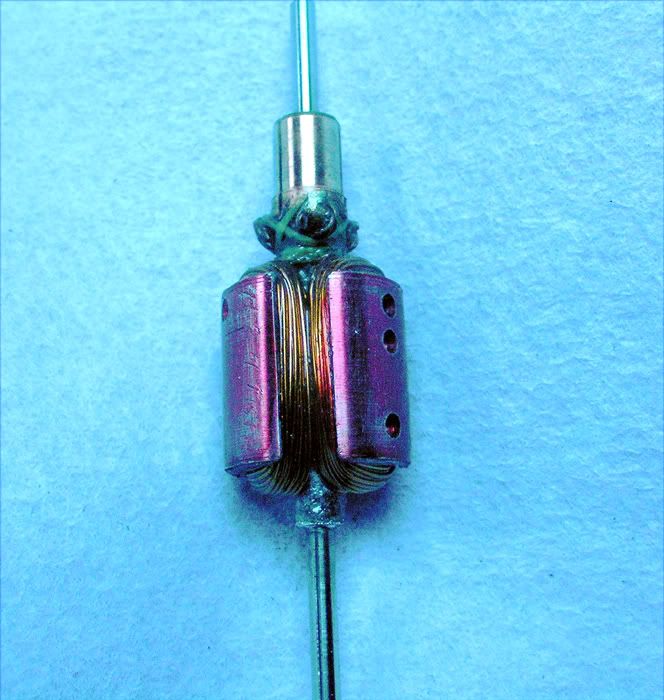

For reference, here's a #30 triple wind (I think...it may even be a #29 triple...I forget, but most likely a #30) I did a year or two ago on a long Mura .007" lam stack with a Mura com. ** Correction, I just noticed that the stack engraving seems to say it's a #29 triple

Neither of these are "layered" or "series" doubles. Both were wound with multiple conductors being fed simultaneously. I don't know that either is "better", but I suspect this way "might" be better.

-john

#2753

Posted 10 April 2011 - 10:29 AM

I always had better results with two or three parallel wires on a simultaneous wind rather than layered.

The limit is always that of the set up, however. No Scaley S can is going to take a 30 double!

Fate

3/6/48-1/1/12

Requiescat in Pace

#2754

Posted 10 April 2011 - 10:35 AM

I always had better results with two or three parallel wires on a simultaneous wind rather than layered.

Makes sense to me Rocky, although I don't have anything more than an educated guess to go on.

The limit is always that of the set up, however. No Scaley S can is going to take a 30 double!

Sure...but setups have come a long way. Yes on the S can also...but they can be cut down, have a real end bell fitted, magnets replaced and so on. There are always lots of neat and interesting projects to attack.

-john

#2755

Posted 10 April 2011 - 05:43 PM

#2756

Posted 10 April 2011 - 07:20 PM

-john

#2757

Posted 10 April 2011 - 07:42 PM

Don Weaver

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#2758

Posted 11 April 2011 - 05:38 PM

Is their a rule of thumb to go by on triple and quad winds? I know a double is equivalent to 3 wire sizes smaller. So is a triple equivalent to 4.5 sizes smaller and a quad 6 sizes smaller? Would a 30 turn quad wind 32 gauge be like a 30 turn 26 gauge?

A 60/28 wound as a 30/28/2 would be the equivalent of a 30/25, wound as a 20/28/3 would be the equivalent of a 20/22, and wound as a 15/28/4 would be the equivalent of a 15/20. 3 gauges for a double, 6 gauges for a triple and 8 gauges as a quad. In practice it isn't quite this neat due the extra lengths of wire going to and from the tabs but this is pretty close.

So hard a judge they hope never to meet as themselves.

#2759

Posted 11 April 2011 - 10:38 PM

I don't know how the math works out, but this motors not that extreme. 8 sizes smaller would be a 23t22g single.

#2760

Posted 12 April 2011 - 05:40 AM

I tried a 30g quad today on a old 36d arm. 3 feet of wire, 4 strands on each pole got me 23 turns and .6 ohms.

I don't know how the math works out, but this motors not that extreme. 8 sizes smaller would be a 23t22g single.

Very cool!...let us know how it worked.

-john

#2761

Posted 12 April 2011 - 07:46 AM

So hard a judge they hope never to meet as themselves.

#2762

Posted 12 April 2011 - 09:53 AM

In the early 90's I raced R/C cars and some of the best motors were quad and quint winds. They had more rpm ,drew less amps and had less torque so they were easier to drive.

#2763

Posted 12 April 2011 - 11:51 AM

This is an old and possibly unreliable memory, but what I remember from when I was doing these was "3-6-9-12", 2x30s are a 27, 3 are a 24 and so on.

Fate

3/6/48-1/1/12

Requiescat in Pace

#2764

Posted 12 April 2011 - 12:44 PM

No rule says that multiple conductors all have to be the same gauge either.

Sure thing and mixing conductors is probably as old as rewinding in slots. 28/29 was a popular one, and those arms are still out there as NOS or just "old"

-john

#2765

Posted 16 April 2011 - 09:48 PM

- MarcusPHagen likes this

#2766

Posted 17 April 2011 - 08:58 PM

So hard a judge they hope never to meet as themselves.

#2767

Posted 17 April 2011 - 10:07 PM

What Martin said! Sounds like you do have some potential there though because, an exploding com is one sign of horsepower!

-john

#2768

Posted 17 April 2011 - 10:41 PM

#2769

Posted 18 April 2011 - 05:43 AM

Yes, the coms are pretty weak, although for mild rewinds (single #29) they seem OK. 36D endbells have enough room for modern coms, although sometimes the inside of the hardware and plastic needs to be clearanced a little to make room for the com tabs. If you come across any, there was a Champion 36D commutator that was much better and should work for short blasts (I think) on a 36D drag car. I just wound three 36D doubles for a Blogger and he had me use Mura coms, and those have to be reamed-out for the larger shaft size of the 36D. I really don't like doing that as the com cuts vary in depth and on some coms, the larger hole seems to come too close for comfort...but he tells me they've been doing this apparently without many problems!? The big fat modern Mura "Diamond-Cut" coms have more material and seem a better choice for this, but if you ever decide to try this, don't drill out the shaft hole. A twist drill will torque it's way slightly off center going through the tough phenolic. A small burr or (if you can find one) a tiny reamer is better. I may try a 36D quad sometime thanks to your inspiration

-john

#2770

Posted 18 April 2011 - 07:29 PM

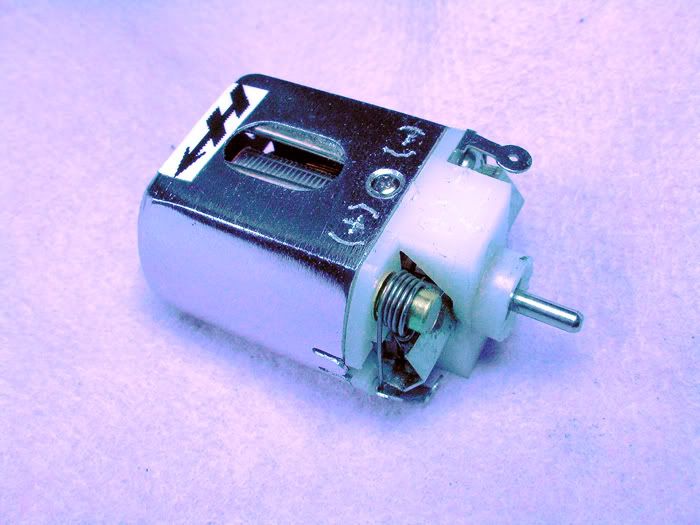

The endbell got 36D hoods and heatsinks (brush tubes) that were clearanced on the inside for the larger com, aligned and soldered...as well as a set of post protectors. I widened the can countersinks for the retaining screws and that was about it. With a set of Camen springs, the motor sings a sweet song, drawing only about an amp or even a bit under but pulling strong all the way to 12V where it really sounds like a rewind

-john

- MarcusPHagen likes this

#2771

Posted 18 April 2011 - 09:54 PM

Thank you very much John! U DA MAN!

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#2772

Posted 19 April 2011 - 05:38 AM

As is often the case with the 26D's, the coil is pretty close to the rear of the can so it you use a rear bracket, make sure the screws aren't too long.

-john

#2773

Posted 19 April 2011 - 11:58 AM

It's a good thing I'm right handed.... self abuse is hard... offhanded!

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#2774

Posted 19 April 2011 - 01:11 PM

This topic is locked

This topic is locked