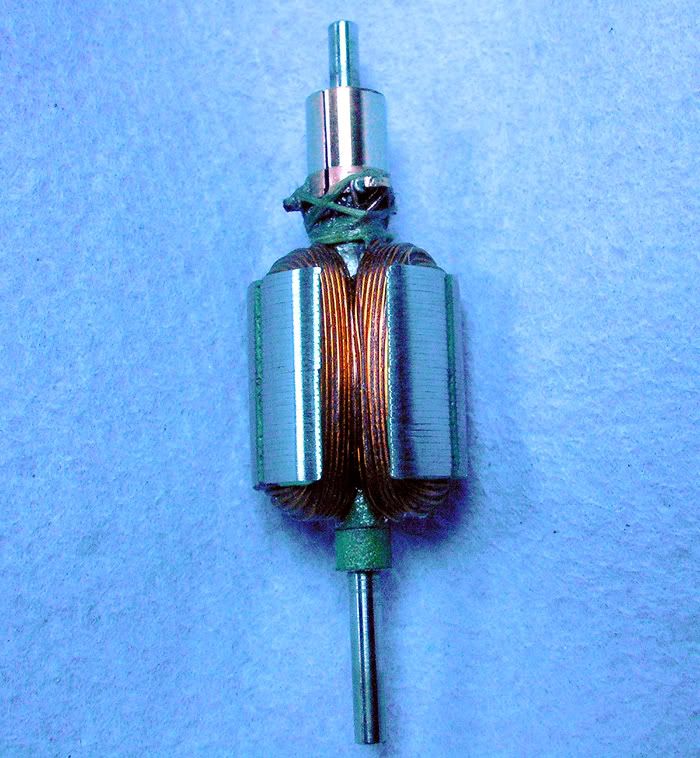

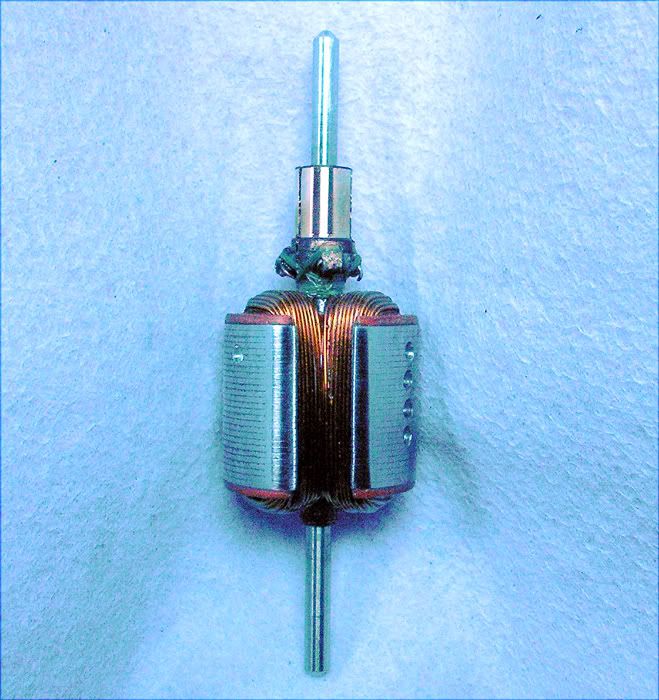

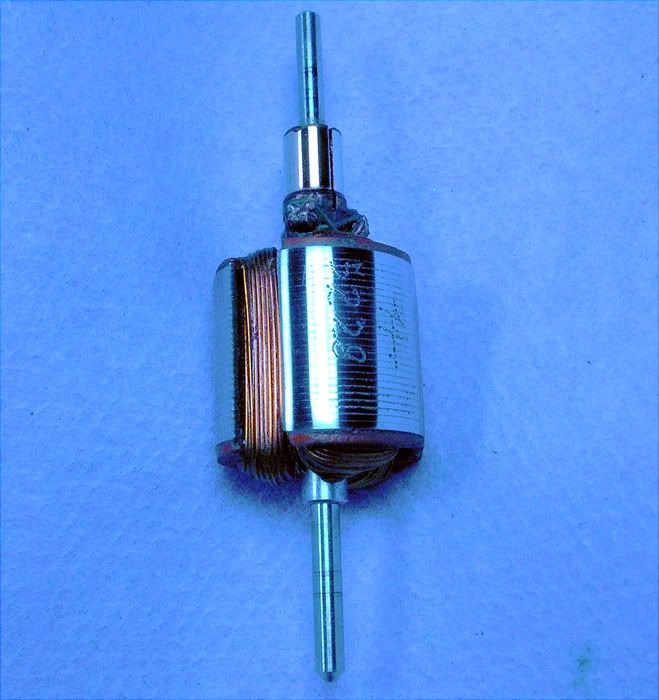

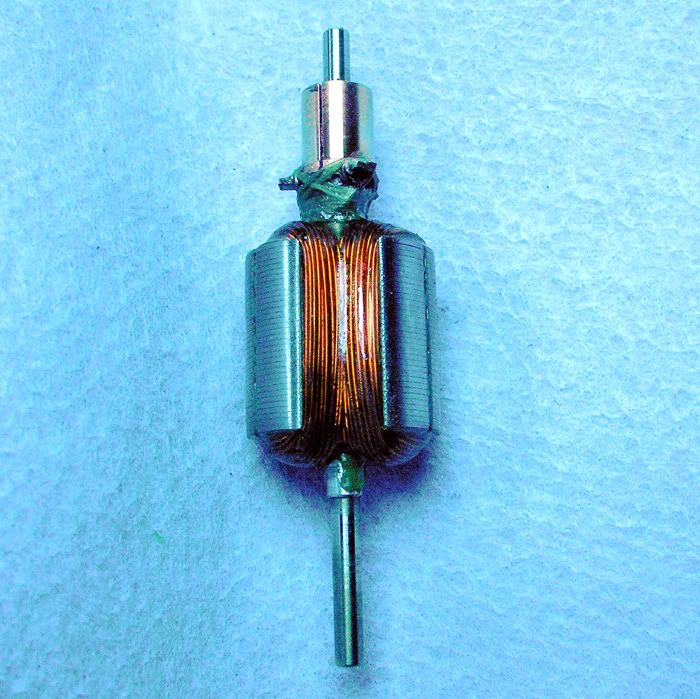

I got inspired to do up a 36D after learning a little about these races at BPR. I wound two #28 arms:

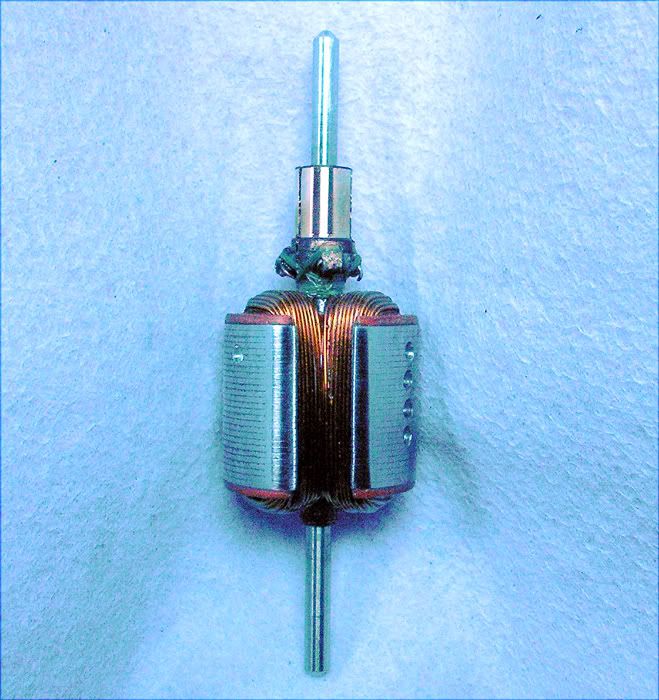

First one seemed a little timid, but runs strong and pretty danged cool:

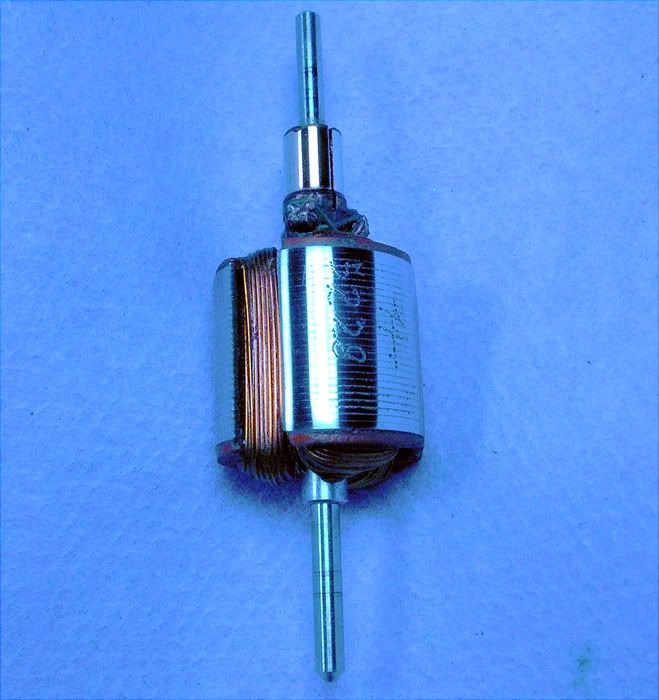

Second one seems about right as a balance between "heat" and longevity...more bettererestest:

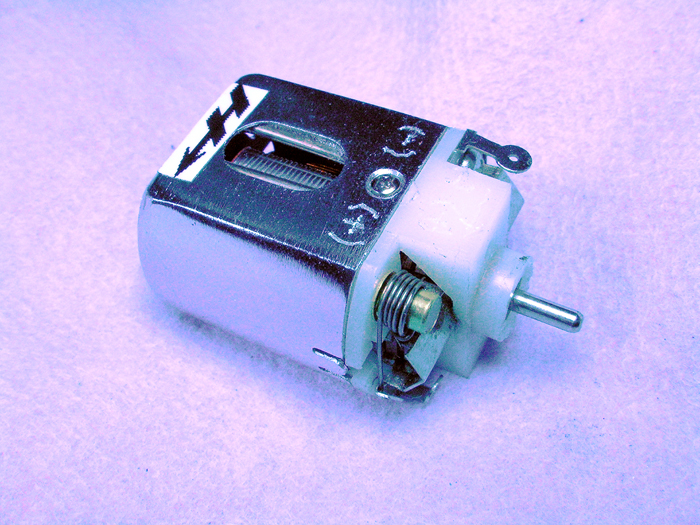

Both were done on Tradeship (French) blanks with Mura coms reamed out and welded. Of course, they had to be installed in something to see how they run so a "Big Block" was in order. I guess in keeping with my "mixed nuts" series of motors, this one would be a Brazil Nut or maybe even a "Coconut"

As seems to be the custom, I fabricated a set of brush plates with leadwire tabs and installed some Parma hoods over those. I was going to make a set of "elephant ears" for extra cooling, but I don't think it needs them so I stuck a fork in it and called it "done". I might do another as a double wind, but I think a single is appropriate for these.

-john

This topic is locked

This topic is locked