#2826

Posted 11 May 2011 - 08:11 PM

Even now John, each and every rewind you share on the forum, intrigues, fascinates and excites me - just like the first time!!! Also the motors that Vic and Robert (pardon me please if I've left anyone out that has posted their rewind) get me inspired and excited!!

Thank you gents for sharing!

Ernie

#2827

Posted 12 May 2011 - 05:17 AM

-john

#2828

Posted 12 May 2011 - 11:58 AM

Requiescat in Pace

#2829

Posted 14 May 2011 - 09:17 AM

-john

- MarcusPHagen likes this

#2830

Posted 14 May 2011 - 10:03 AM

Great work on that 36D i didn't think they could handle that kind power but it sounds like it runs pretty cool so the end bell should hold up, now i wonder what gear will fit on that shaft

#2831

Posted 14 May 2011 - 10:49 AM

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#2832

Posted 14 May 2011 - 12:51 PM

Hi John

Great work on that 36D i didn't think they could handle that kind power but it sounds like it runs pretty cool so the end bell should hold up, now i wonder what gear will fit on that shaft

Thanks Robert, I "overwound" the arm figuring on more torque and it does feel and sound great while staying cool. On the gear, that's easy...guys have been polishing down drill blank shafts for a looooong time to fit bearings. On this one, it's even easier as the arm doesn't have to be removed from the setup. A piece of #600 wet/dry paper on the spinning arm will take down those couple of extra ten-thousandths in no time.

Great work John but it's endbell drive so maybe a "cross" or a "T" strap for the bearing support with holes so you can mount it to a motor bracket????

Hi Barney,

The motor can go either endbell drive or can drive and either inline or sidewinder as is with a bit of creativity. For sure, cab drive (with the "circlip") and inline would be the easiest though. For mounting endbell drive, the bottom screw can be removed for mounting in a "half-bracket" and then reinstalled, or even both (carefully)...the bearing strap screws are long enough.

-john

PS...hey, "Arm Winding" is past 100,000 views! I guess my work here is done!

#2833

Posted 15 May 2011 - 08:45 AM

Not even close John

So hard a judge they hope never to meet as themselves.

#2834

Posted 15 May 2011 - 10:47 AM

-john

#2835

Posted 15 May 2011 - 11:34 AM

Don Weaver

Don Weaver

A slot car racer who never grew up!

The supply of government exceeds demand.

L.H. Lapham

If the brain-eating amoeba invades Washington

it will starve to death...

#2836

Posted 15 May 2011 - 12:33 PM

When this first started I wondered why anyone would want to wind arms anymore

...oh I got that a lot back then

-john

#2837

Posted 15 May 2011 - 01:02 PM

So hard a judge they hope never to meet as themselves.

#2838

Posted 16 May 2011 - 12:53 PM

Other than the occasional humbling experience, I'm not so much into building cars as just motors. I look forward to doing some drag motors though, maybe even some HO stuff at some point.

-john

#2839

Posted 17 May 2011 - 06:28 AM

-john

#2840

Posted 18 May 2011 - 10:15 AM

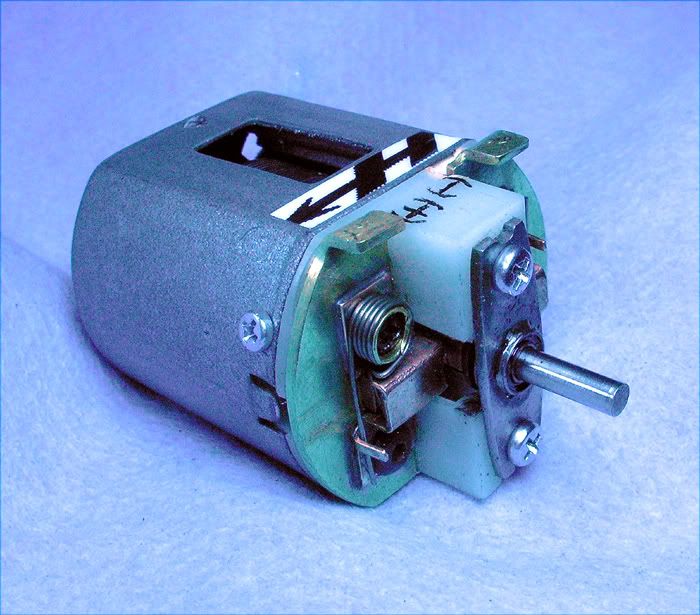

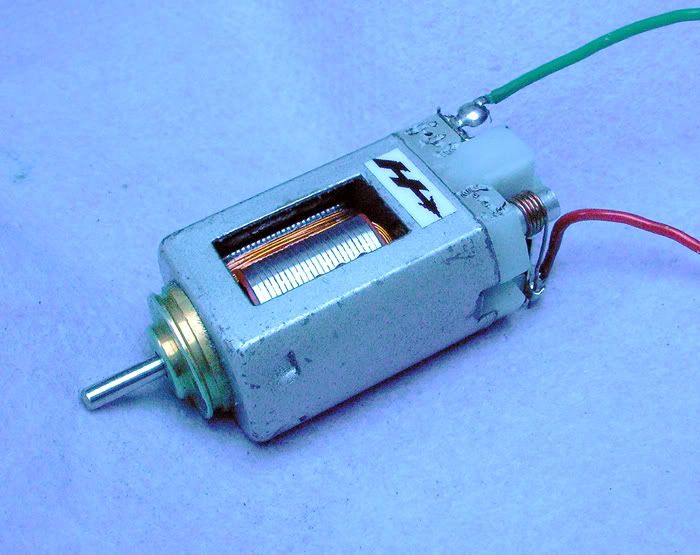

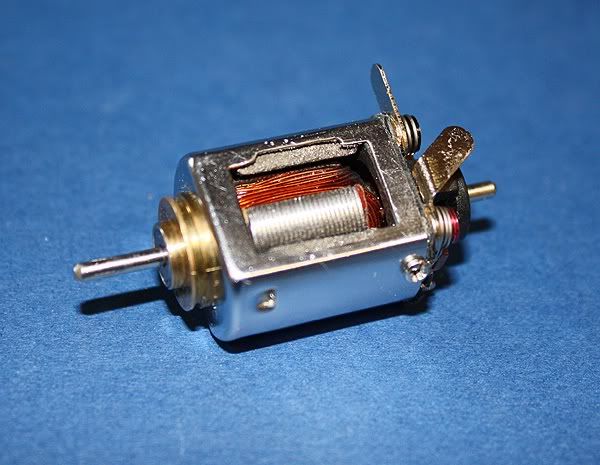

-65T/#30 awg

-New ceramic magnets

-Post protectors/sleeves (aluminum)

-Tradeship Commutator on the original stack

First up here was to ditch the original "magnets". I have some small and thin ceramics here that measure around 900 on my meter, which is honkin' strong for these things. They required a bunch of whittling to get them in there, and I epoxied them in with some JB Weld. Next was the arm, and I replaced the stock com with a Tradeship which, because of it's height was a good fit, allowing the com tabs to ride safely below the inside of the endbell. I did what would normally be a pretty mild wind (65T/#30) and then took the extra precaution of sleeving the spring posts with some aluminum tubing which was a really nice snug fit. With Camen "light" springs, the motor really spun up with authority, but was drawing around 1.4 amps and getting a little warm. I then straightened a set of D motor springs and they were much better. Now the motor only draws around .6-.7 ohm, stays nice and cool and has more revs as you would expect from the lighter tension. What a great little motor this is now, and small enough to fit about anywhere in anything while retaining the period (rewind) appearance.

-john

- MarcusPHagen likes this

#2841

Posted 18 May 2011 - 12:21 PM

We would have killed back in 65/66 to have magnets like that!

Grin.

Before the good magnets, however, the C can came out and a lot of us were turning down the Ccan endbell to use. Frankenmotors.

Fate

3/6/48-1/1/12

Requiescat in Pace

#2842

Posted 18 May 2011 - 12:44 PM

Nice work on that 13d they are great little motors and a perfect fit for a vintage F1 car, amazing the difference the springs make on amp draw i would not thought it would be that big.

#2843

Posted 18 May 2011 - 12:55 PM

- MarcusPHagen likes this

#2844

Posted 18 May 2011 - 01:47 PM

Your arms look better and better all the time...you're a quick study!

Nice work on that 13d they are great little motors and a perfect fit for a vintage F1 car, amazing the difference the springs make on amp draw i would not thought it would be that big.

Oh heck yeah. The current draw dropped almost 50% on this motor and with the new magnets still sounds like it has plenty of torque and "natural" braking...plus more revs. It's always a tradeoff though (revs and lower current draw vs grunt and higher current draw) and I keep all kinds of springs lying around here and several different gauges of wire for winding springs, because it's such an important part of how the motor will ultimately perform. 10-4 on the F1 thing too. Now that the little homeset motor is safely up in FT16D rewind territory, a really skinny and vintage inline F1 car would be just the ticket. With the right rubber and chassis, it would probably be a handful to drive...and loads of fun.

-john

#2845

Posted 18 May 2011 - 01:54 PM

Hi

We would have killed back in 65/66 to have magnets like that!

Grin.

Before the good magnets, however, the C can came out and a lot of us were turning down the Ccan endbell to use. Frankenmotors.

Fate

Yeah...tell me about it Rocky, and these are "only" ceramics! Stock, these motors are so anemic it's really astounding in retrospect because they didn't seem so bad when I was a kid. I guess that's because nothing was blindingly fast like the later motors. The endbell hardware on these things is awfully simple, but the two-piece formed metal brush channels are fine...actually sort of similar to the later Mura setup with the hoods and bottom plates, although the brush fit is a bit sloppier. Frustrating, but cool little motors.

-john

#2846

Posted 18 May 2011 - 02:54 PM

I agree with John, your work gets better and better each time you post here. Now im really jealous lol

Vic

#2847

Posted 18 May 2011 - 10:28 PM

#2848

Posted 19 May 2011 - 05:38 AM

Doubles are still a viable option and it's definitely a good thing to get a few under your belt to see what that's all about. If you really want to dig in a little deeper, you can do layered or "serial" doubles or parallel doubles where you wind both conductors at the same time. If you do layered doubles, try one pole to get an idea of how much shorter the top layer should be by removing the wire afterwards and measuring each layer. You can then subtract say (just as an example) two turns from the top layer so both layers are about the same length. They don't have to be super exact for the double to work. Keep up the great work!

-john

#2849

Posted 19 May 2011 - 06:53 AM

Your package arrived yesterday, so I spent last night in my workshop checking everything out. The 36D arm looks sweet - I can't wait to get it in a decent setup to give it a try. I zapped the magnet in the Atlas motor and that arm spun right up on 3 volts. It screams at 12 volts and is very smooth. Thanks for reviving this old motor for me!! Now to build a car for it. .

JB

Requiescat in Pace

#2850

Posted 19 May 2011 - 07:24 AM

Thanks for the update...I was pretty sure the magnet was dead and it's good to know the motor works well now! The arm was one of those that was so short that I had to wind it without the com on and the wires hanging loose and install the insulator ring and com afterwards. The 36D arm is a nice conservative wind that should live well even in a pretty stock setup...although Arcos would definitely be a plus. Enjoy Jeff

-john

This topic is locked

This topic is locked