BTW- I finally got some different size wire, so now I can try another wind using the right size wire lol.

Vic

Posted 26 May 2011 - 03:57 PM

Posted 26 May 2011 - 05:45 PM

Posted 26 May 2011 - 06:47 PM

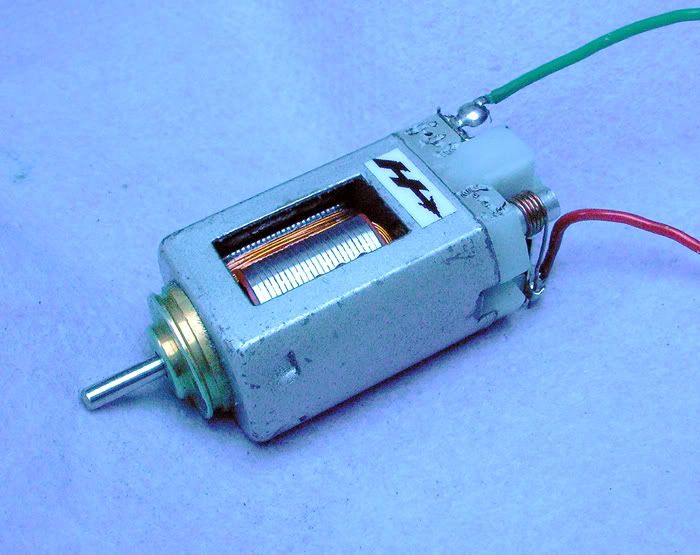

Yep i am with everyone else john keep posting your wonderful motor builds it's also the first section i check when i log on and i am really a slot body painter that's what i really do well, Vic that little motor looks very fast let us know how it works out, also glad to here we may be seeing more rewinds from you i can't wait to see what you come up with.

Posted 26 May 2011 - 11:00 PM

Posted 28 May 2011 - 08:24 AM

Posted 28 May 2011 - 08:37 AM

Posted 28 May 2011 - 09:18 AM

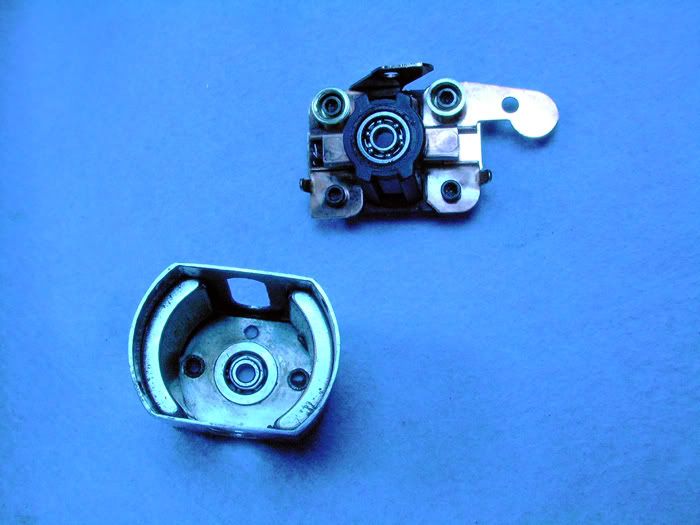

Is that a 13D in the upper left corner? If so can you show more about that one

Posted 28 May 2011 - 09:58 AM

Thanks guys

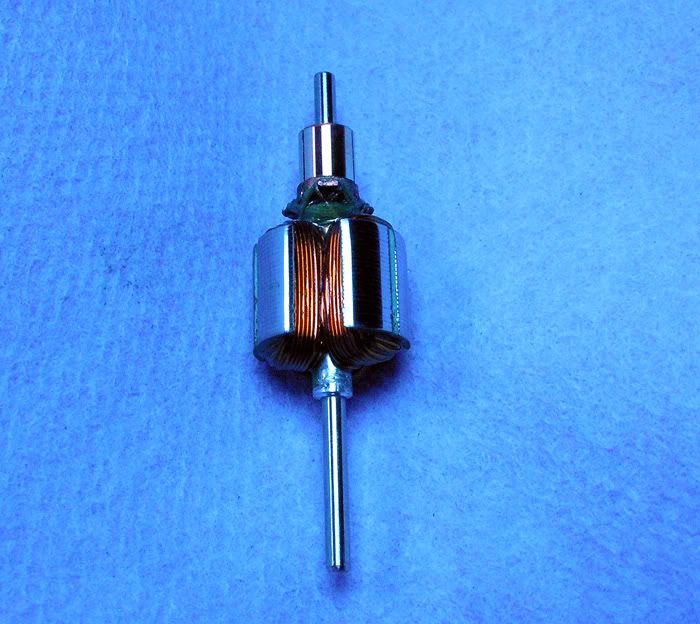

Here's a pair of arms I did for Marty N. He specified a 65T/#30awg wind on Bill Bugenis stacks and coms, and to a length to fit a Hawk setup. This was a cool job for me because 65T/#30awg (as well as 50-55T/#29awg) is my favorite "manageable wind" for Mabuchi FT16D motors. In the Mabuchi, it's a very strong wind with lots of torque and much better top end than stock...yet it can live with some minor tweaks to the Mabuchi setup...post protectors, better springs and magnets. Here, the wind is on a shorter stack with a much MUCH better com (welded) and will reside in a thoroughly modern setup. They should run really well! Marty will send them out for dynamic balancing, but I kept the epoxy to a minimum, polished the stacks and cut the coms.

-john

Posted 28 May 2011 - 10:09 AM

Posted 28 May 2011 - 10:48 AM

I do like to share the builds, but never want to wear out my welcome here at SlotBlog!

Posted 28 May 2011 - 11:39 AM

Posted 28 May 2011 - 11:43 AM

All of them are Very, very nice!

John, what material do you use to tie up with?

Posted 28 May 2011 - 12:46 PM

Posted 28 May 2011 - 12:58 PM

Posted 28 May 2011 - 01:48 PM

Posted 28 May 2011 - 02:50 PM

Posted 28 May 2011 - 03:58 PM

Posted 28 May 2011 - 05:12 PM

Posted 28 May 2011 - 06:09 PM

Posted 28 May 2011 - 06:13 PM

anal-retentive,

-john

Posted 28 May 2011 - 06:14 PM

Posted 28 May 2011 - 07:37 PM

Wow @ 102,075 Views this is a hot topic. More then some lady GaGa youtubes

BTW doesn't timing effect direction?

If the south magnet is at the rear, what happens when these are shipped down under?

Posted 29 May 2011 - 05:31 AM

Wow @ 102,075 Views this is a hot topic. More then some lady GaGa youtubes

BTW doesn't timing effect direction?

If the south magnet is at the rear, what happens when these are shipped down under?

Posted 29 May 2011 - 08:37 AM

Posted 29 May 2011 - 10:08 AM

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!