#2926

Posted 04 June 2011 - 06:53 PM

#2927

Posted 05 June 2011 - 07:42 AM

When I saw that I had overlooked such an obvious detail, I felt like a complete dumb-***. I had no choice at that point other than to run (not walk) down to the man-cave and correct things. I have to say that the whole spirit of this series, starting with Jairus and including the track owners as exemplified by Mike Swiss' great first leg, has been contagious. Except for a little griping here and there about points and rules, everyone seems to be stoked and helpful.

-john

#2928

Posted 05 June 2011 - 09:13 AM

#2929

Posted 05 June 2011 - 10:12 AM

-john

#2930

Posted 07 June 2011 - 03:26 PM

-john

#2931

Posted 07 June 2011 - 04:06 PM

Thank you John, it looks cool!

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#2932

Posted 07 June 2011 - 06:46 PM

So hard a judge they hope never to meet as themselves.

#2933

Posted 08 June 2011 - 05:44 PM

#2934

Posted 09 June 2011 - 05:24 AM

-john

#2935

Posted 10 June 2011 - 10:52 PM

So hard a judge they hope never to meet as themselves.

#2936

Posted 11 June 2011 - 08:53 AM

-john

#2937

Posted 11 June 2011 - 10:04 AM

So hard a judge they hope never to meet as themselves.

#2938

Posted 11 June 2011 - 10:50 AM

I've got a better rundown somewhere back in this thread but here's the basic deal for a "homebrew brazing setup":

1) You need a source for high current at relatively low voltage. You need the high current (amperage) for generating a lot of heat fast, but you want low voltage because the higher the voltage the more likely you can inadvertantly strike an arc and any arc even for a split second can vaporize the com tab and the magnet wire attached to it. I use a "car-starter/battery chanrger" that can do 55 amps at 6V DC. Even lower voltages around 2-3V would probably be better but, short of a very expensive lab-type power supply (most less expensive lab power supplies do low amperage), it's the best I could find.

2) You need a conductor material that also high-resistance. This will be the "heater element" that, when fed the high amperage, will glow red-to-yellow hot quickly since even the "low-temp-melting" silver brazing metal needs over 1000 degrees F to flow. You can use carbon brazing rod (clad with copper) or the carbon electrode from wither a "C" or "D" sized oldstyle zinc/carbon battery. When sharpened to a point, these will heat up PRONTO when touched to the com tab, fast enough to not damage a modern com but still cause the brazing metal to flow.

3) You need a way to turn the current on and off quickly without using your hands since they'll be busy holding both the heater element and the silver brazing wire...not to mention possibly stabilizing the arm while brazing (I adjust the tension on my arm crank to help hold the arm still and in position). To turn the current on and off, I mounted a momentary single pole switch in a plastic project box that is rated for this amount of current...turns out a that a boat ignition switch I found online is perfect. I trip this switch with my foot to turn the current on and off.

4) You need a way to connect the negative lead from the power source to the com. I soldered a piece of brass tubing that I split in half to a clamp that has the negative lead attached to it. After cleaning the com with Scotchbrite to assure a good electrical connection, I can simply clamp the negative lead on the com without marring it.

5) You need a clamp to hold the carbon rod...the positive lead from the car-starter will go to the boat switch and then another lead coming from the boat switch will have the clamp and carbon rod on the end of it.

6) Of course, you need brazing metal. "Brazing" is like very very high temperature soldering since you're using another metal to fuse the components, rather than welding them directly together. You CAN do resistive "spot welding", but that's even more involved than brazing and from what I gather, brazing is better. Anyway, I use a powdered silver/brazing flux in a syringe...but now only as a flux that will also put a small amount of silver on the joint since it doesn't have enough solids in it to confidently make the connection every time. I also feed silver brazing wire on the joint as I heat it. I run this wire through a "draw plate" with succesively smaller holes in it until it's pretty fine...maybe the equivalent of #27 awg. I also usually hit each joint several times (cleaning off the tab between each "hit" with a small wire brush) to be sure any insulation I may have missed has been burned off and that (hopefully) the silver has flowed into all the minute "nooks and crannies" and fused the magnet wire well to the com tab. Besides being VERY careful to not strike an arc, you need to heat the tabs enough to fuse the silver and not melt the tab...or at least not melt it enough to damage it or the com proper.

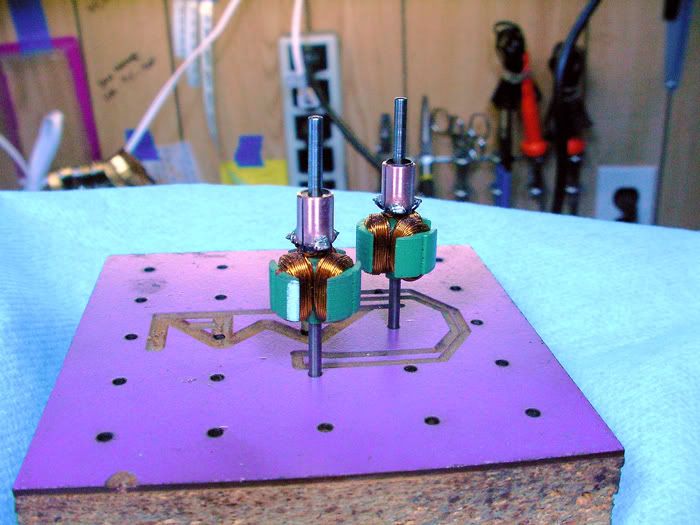

Here's a couple of #30 awg double winds (parrallel using two wires being fed as a pair...not "layered" doubles) for eurosports I just did for Bill Bugenis on very short (.250") stacks that have just been brazed. Tough as heck to keep things neat with such short arms and my "vintage" eyeballs, but I'm pretty happy with them. Anyway, they test OK on my meter, but for such a critical end use as these arms are destined for, being off slightly resistance-wise from pole-to-pole because of the brazed connection can mean the difference between being good or trash. Doing a big wire Mura is like going on vacation compared to these things! They're ready to go out to Bill for finishing...tie/epoxy/stack grind/coms capped and cut/stack grinding and balancing.

-john

#2939

Posted 13 June 2011 - 07:28 AM

How about the Kevlar thread? Source?

So hard a judge they hope never to meet as themselves.

#2940

Posted 14 June 2011 - 05:42 AM

That made my head hurt just reading it

I'll have to see what I can scare up.

How about the Kevlar thread? Source?

...well, you did ask!

I've gotten kevlar thread from Amazon a couple of times. If you go there and search or just do a Google search, you should find it easily. It's often used for tieing flies for fishing so it might be sourced through a fishing supply website. Lightweight kevlar leader or "string" might be even better as long as it's not too thick.

-john

#2942

Posted 14 June 2011 - 06:11 AM

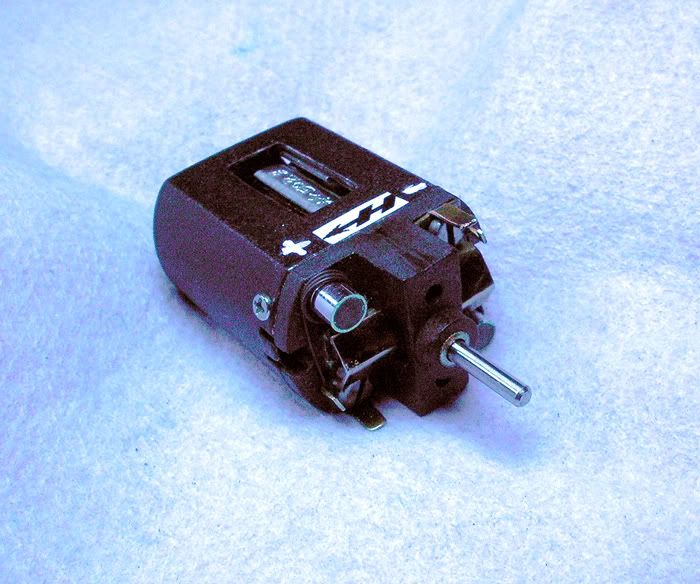

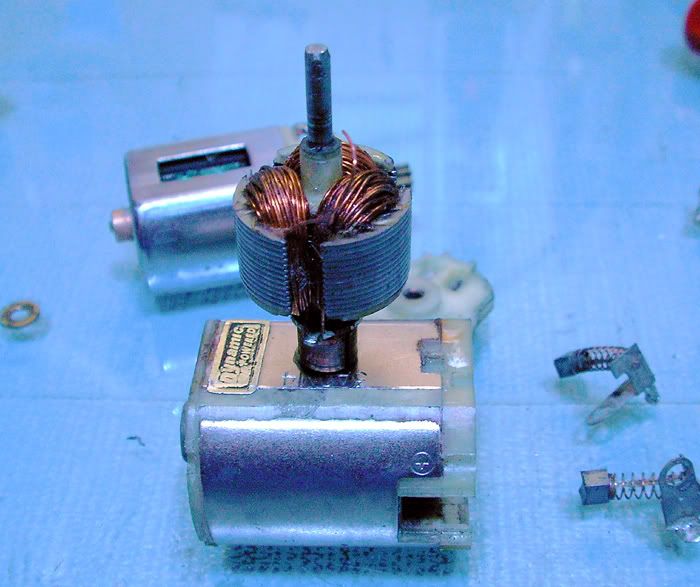

This was the first time I have ever worked on one of these and they're pretty neat motors, fairly compact considering there's a slightly oversized 36D sized short stack arm in there. It's a very well engineered motor made in the USA out of seemingly excellent materials, with the exception of the arm bushings...although installing/modifying a set of better bushings/bearings seems do-able. The brushes are more of the typical industrial type and in this case heavily worn, and I have no idea where a new set might be sourced. The magnets are paper thin but surprisingly read up in Arco territory on my meter.

I stripped the arm and tossed what was left of the stack insulators, installing a set of 36D fiber insulators. They're short at the tips for the GE's wider pole pieces, but fit well in all the critical places and rewound the arm. I couldn't get it completely balanced, but it's better than stock in any case. The com is a nice beefy piece that just got a cleaning with some Scotchbrite:

I cleaned the motor inside and out and, after reassembly I was able to maintain the fairly neutral timing of the stock motor and it spins about the same in either direction. The motor draws about 1 amp at 6V, runs strong and seemingly has very good natural braking. Those brushes are about gone and will certainly need to be replaced, but it's a cool motor that's ready to go into a period car otherwise.

-john

#2943

Posted 14 June 2011 - 09:38 AM

Didn't even know that it was sent to you... which was not a problem. I just figured it was impossible to find replacement parts.

I will see about aquiring a new set of brushes.

Thank you John!

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#2944

Posted 14 June 2011 - 10:44 AM

#2945

Posted 14 June 2011 - 11:36 AM

Nope...this is another GE is from Peter Horvath. Racing 50 year old motors, things are bound to go wrong

Lionel ho engines in the late 60's early 70's have the ge motor in them!!!! Search on e-bay for a used one and you have a new motor [or parts motor].

Thanks for the info John, but these cannot be the same as any motors GE produced for HO. The motor alone is larger than an HO scale car

-john

#2946

Posted 14 June 2011 - 11:47 AM

Thanks for the clarification on the GE.

J

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#2947

Posted 14 June 2011 - 12:04 PM

Actually, what's surprising is how well a lot of these 40-50 motors still run - just found an old slot car on ebay with a Globe motor and that thing powered up right away and screamed like a banshee!

Dynamic did their own rewound version of the GE motor, with 26 wire I think - kind of a rare beast, and undoubtedly a light-dimmer, but that would give you something to shoot for John...

Don

#2948

Posted 14 June 2011 - 12:28 PM

Locally, a couple of my friends have GEs in Dynamic frames that were Christmas presents their parents gave them when new. And they have been racing them for fun against each other since! One of them has recently slowed down, and I have promised to get around to going through it for my friend.

Like the pittmans, sort of over designed for the application back then.

Fate

3/6/48-1/1/12

Requiescat in Pace

#2949

Posted 14 June 2011 - 01:29 PM

And there was an industrial version of the GE motor, which may be a bit easier to find, and could be cannibalized for spare parts - of course, a batch popped up a couple years ago, but may be harder to find these days...

Actually, what's surprising is how well a lot of these 40-50 motors still run - just found an old slot car on ebay with a Globe motor and that thing powered up right away and screamed like a banshee!

Dynamic did their own rewound version of the GE motor, with 26 wire I think - kind of a rare beast, and undoubtedly a light-dimmer, but that would give you something to shoot for John...

Don

Hi Don...after opening this one up, I was really surprised to find what measured (aside from the possible difference in thickness of the insulation) to be #28 wire!

Thanks for the clarification on the train motor thing Jairus!

-john

#2950

Posted 14 June 2011 - 01:45 PM

And one day we'll find the electric toothbrush that it supposedly powered...

Don

This topic is locked

This topic is locked