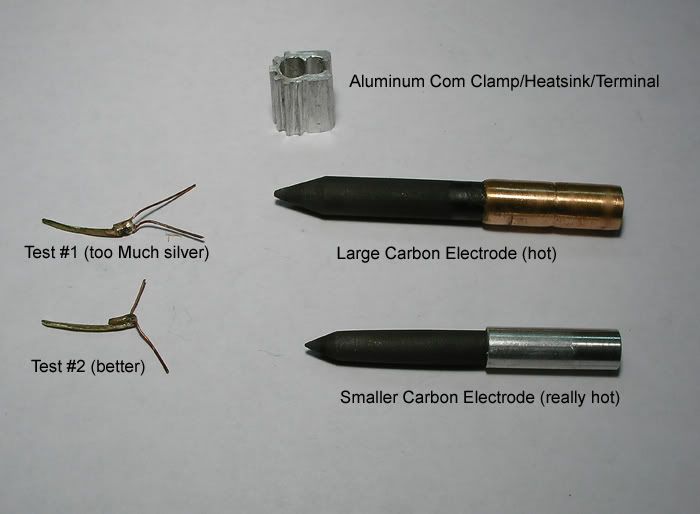

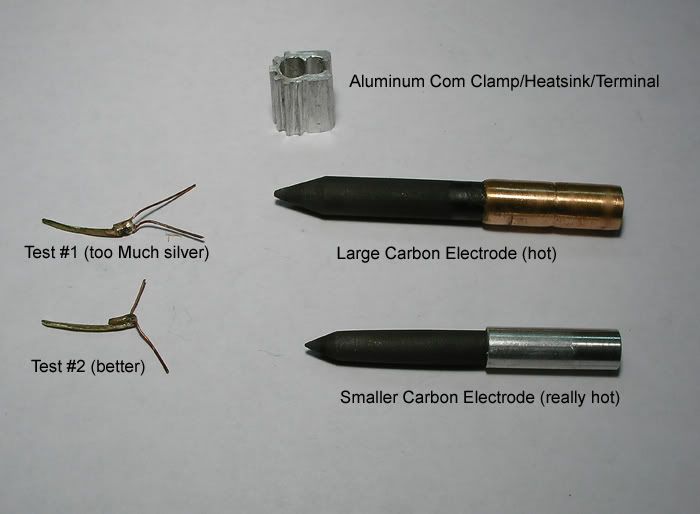

I finished some quick and dirty tests using some brass cut into thin/small strips and bent to simulate a com tab with a piece of magnet wire layed in.

Test #1 clearly shows the silver and I think it's a bit heavy (although this stuff is almost pure silver and should be a great conductor.

Test #2 is a neater job with the silver barely showing. This stuff melts/flows at around 1200°F so I doubt there will be much trouble from these connections.

I made two carbon electrodes using "D" cell carbon/zinc batteries and shaped one down to test how their different sizes would affect the process. The larger carbon electrode is easier to control than the smaller one since it takes maybe 2 seconds to complete the "weld". The smaller one will almost melt the brass in that time and without some sort of timing relay to precisely control weld time, is too risky. Maybe if I get the timing setup sometime, I may try that one again for like 1/2 second or so.

I'm also showing the heatsink/negative electrode com connection thingie. When clamped with the negative lead, it tightens snugly around the com and should prevent any heat damage by siphoning-off heat. The whole process goes so fast that I don't know that the com would get that hot anyway, but it seems like a prudent measure to take.

I also did some tests with "SolderIt", which is a low temperature powdered solder/flux. It flows at only 450°F, but will only remelt at over 600°F. It works fine with an ordinary soldering iron and is probably good for really mild winds or even chassis work requiring extra strength (soldering-in a motor etc.), but I probably won't be using it for the com connections since brazing/welding with silver doesn't seem to be much of a problem.

***Note: The above is for informational purposes only. If someone tries this stuff and blows themselves up, tough luck

This topic is locked

This topic is locked