-john

#201

Posted 28 February 2009 - 06:01 PM

-john

#202

Posted 28 February 2009 - 06:46 PM

My life fades, the vison dims. All that remains are memories... from The Road Warrior

#203

Posted 28 February 2009 - 07:30 PM

The way I look at it... the larger the com diameter, the longer the brushes are in contact with the segments that are "firing". If I think about how these motors work...well...it seems as though they shouldn't work at all and I get a headache

-john

#204

Posted 01 March 2009 - 08:35 PM

-john

#205

Posted 03 March 2009 - 08:23 PM

-john

#206

Posted 03 March 2009 - 09:17 PM

What wind is on that armature?

#207

Posted 03 March 2009 - 09:40 PM

Super cool!

What wind is on that armature?

Hi Dennis,

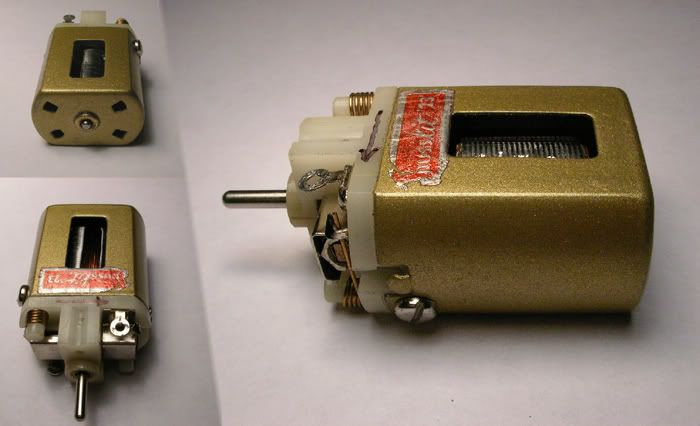

It's a #29 awg and the owner had used this very wind back when it was "current", so he wanted it just the same. It's fairly mild, but sings really nicely, spins-up with authority and seems totally appropriate for the motor. Draws VERY little current and reads about 4+ ohms. I can see this thing doing really well in a period chassis, and I'm sold on these little Russkits! Wish I knew then what I know now

One more thing, the com said "tradeship" but is completely different from the other Tradeships I have here and was almost spot-on...REALLY nice!

-john

#208

Posted 03 March 2009 - 10:11 PM

#209

Posted 04 March 2009 - 06:20 AM

-john

#210

Posted 04 March 2009 - 10:11 AM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#211

Posted 04 March 2009 - 11:39 AM

John,

An advantage of doing this may be a cooler running motor, because the larger comm has more mass. A disadvantage may be slower RPMs. for the same reason.

Tom

#212

Posted 04 March 2009 - 12:40 PM

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

#213

Posted 04 March 2009 - 01:18 PM

Narrowing up the brushes reduces the timing and if too narrow you have an instance in the rotation when only 2 comm segments are touching and this makes for poor power. The reason the bigger dia. comms do not run as well with out a change to a wider or laydown style brush.

For less friction it is always better to keep the brush wider and reduce the height...

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#214

Posted 04 March 2009 - 01:39 PM

I think I understand better now.

"As the comm rotates there should never be a point where the brushes touch all 3 poles at once."

Would it be possible to cut a comm diameter so small that a wide brush would touch all three poles at once?

And do dual points on a car relate in any way to this?

Tom

#215

Posted 04 March 2009 - 01:57 PM

Tony, are you trying to say that one comm segment should not be able to touch both brushes at the same time? This happens when the brushes are very wide in relation to the comm size and you get too much overlap. This short circuit is what kills performance and eats comms.

#217

Posted 04 March 2009 - 03:45 PM

John is that mine?

Yes it is Tony.

"If you take the stock com off a 16D and put the much larger Kirkwood on there (and bigger brushes to boot), they work just fine and I think it's because you still have three segments each representing 120° or one pole. Maybe one of the motor gurus can chime in with the physics"

John,

An advantage of doing this may be a cooler running motor, because the larger comm has more mass. A disadvantage may be slower RPMs. for the same reason.

Tom

Hi Tom,

Yes, I've heard it said many times that the larger coms may run cooler...beats me. Since Tony knows a LOT more about this stuff, I'll leave it to him to 'splain

-john

#218

Posted 04 March 2009 - 04:12 PM

All three segments need to touch at the same time of course. The secret is to reduce the time it takes for the brush to cross over to the next segment. Ideally just as the positive brush (for example) leaves a segment the negative brush will come in contact with it. The more you reduce the "dead time" when the segment is not in contact with a brush the better the motor.

When we were designing a new R/C motor a few years ago a commutation engineer from Carbone came in to visit with our rep. He became very interested in the motors, the fact they were 3 pole and produced the power they did. Within 5 minutes he figured out the brushes were too narrow for the comm size. He got us some samples and that was how our bigger P-94 style brushes were born.

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#219

Posted 04 March 2009 - 04:15 PM

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#220

Posted 04 March 2009 - 04:31 PM

#221

Posted 04 March 2009 - 04:34 PM

Would it also make sense that bigger comm diameter would make for better heat dissipation because of the larger area?

Tom

#222

Posted 04 March 2009 - 05:20 PM

My fastest arms always were the best on the last cut. Sometimes when I would see plastic on a good arm I would try to find another setup were the brushes rode further down the comm just to get another trip on it before it got retired.

Barney Poynor

12/26/51-1/31/22

Requiescat in Pace

#223

Posted 04 March 2009 - 08:15 PM

-john

#224

Posted 04 March 2009 - 08:57 PM

#225

Posted 04 March 2009 - 10:45 PM

(did you solder the brush hoods to the brush tubes?)

Jairus H Watson - Artist

Need something painted, soldered, carved, or killed? - jairuswtsn@aol.com

www.slotcarsmag.com

www.jairuswatson.net

http://www.ratholecustoms.com

Check out some of the cool stuff on my Fotki!

This topic is locked

This topic is locked