Hi Vic...yes, I meant the Hawk endbell. If I remember correctly, it was a fit for the mini motors???

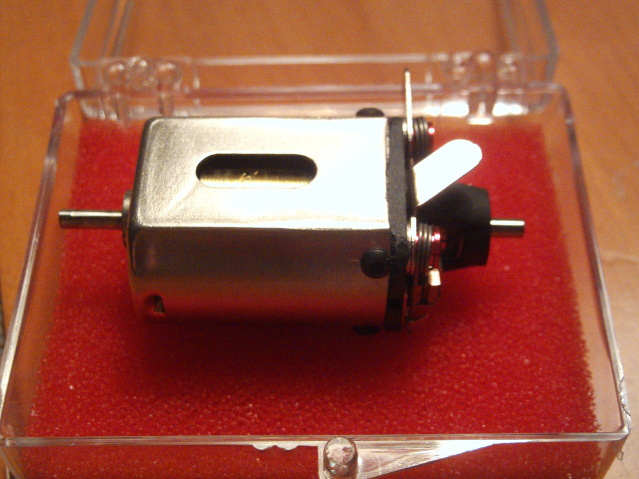

Anyway, further developement on my "mixed-nut series" of shortened, mixed parts motors. I've been working-up winds for the "Strapnuts"...reused minimotors, cut down with C-can endbells. I've settled on a slightly shorter arm after some tests....330" or so seems to work really well in these things (can is shortened a bunch to around .750" long on the outside which is enough to keep the stock magnets and still insert a C-can endbell). Here's a #27 wind which spins up like the dickens and, thanks to the neos, seems to have excellent brakes and torque...even in an open can. Com is a Mura-recycled piece, arm lams were assembled from unknown original burned-up arms and pressed onto a recycled shaft:

I opened up the can "all the way", save for leaving some "radius" on the end nearest the can bushing. This helped greatly to maintain some rigidity in the can and, after screwing the endbell onj there, the whole thing is nice and rigid. Of course, I polished up the can after cutting because of the

"shiny stuff goes faster" rule

Surprisingly, the neos don't seem to lose much, if any, field strength in such a minimalist can. Endbell is all Mura of mixed-vintage...older hardware on a newer endbell. I had the endbell lying around and it's nice and compact, keeping the overall length of the setup short. Brush hoods/hardware are of course from an older Mura which I also had lying around...1+1=3

Anyway, the motor really whistles and I think it will be a strong runner. A couple more of these and I should have some good winds to work with these ...er...

"Strapnuts".

-john

I'm not sure when I'll be coming over yet, since I just got home from Thanksgiving. But my winder does have a 36D holder.

This topic is locked

This topic is locked