#2276

Posted 08 December 2010 - 12:40 PM

I intend to live forever! So far, so good.

#2277

Posted 08 December 2010 - 03:57 PM

If the Russkit endbell bushings are brass, so must have been the blind can bushings

Sure thing Bill. I have to look at them again sometime (the above "22" is" already packaged up to send out), but I'm fairly sure both are regular brass (the color is wrong to be bronze which is a better bushing material...but maybe???). Truthfully, I think good bushings are just as good or maybe even better in many cases than even good bearings. Bronze (whatever particular alloy is used for bushings) has excellent natural lubricity and wear resistance...it's not prone to galling.

You used to see these blind bushings soldered to the cans so they didn't come loose.

But you are correct, we didn't get hotter than a 110/32 to live.

Amazing looking back now Rocky that a #32 wind was considered...er...risky

-john

#2278

Posted 08 December 2010 - 04:37 PM

Thats because we have serious magnets now. This is one of the reasons the mini ProSlot motrs get hot with X12's, they have magnets that are marginal for that wind.

Mike Boemker

#2279

Posted 08 December 2010 - 04:52 PM

-john

#2280

Posted 08 December 2010 - 06:58 PM

I weighed a couple of motors for comparison, no pinions or solder on them.

I took a stock JK Hawk motor and weighed it. It tips the scale at 21.3 grams. I then took the Hawk motor that Sir John rewound for me and it tipped the scale at 21.4 grams. Not much of an increase at all.

Then, I weighed a stock Mura Challenger II, weighed in at 28.4 grams. Sir John did a hot rewind on a Challenger II I sent him and it weighed less!!! It weighed 28.3 grams.

I presumed there would be much more of a weight difference, but from my little comparison there isn't.

Just thought I'd share my findings. Thank you.

Ernie

#2281

Posted 08 December 2010 - 07:43 PM

I intend to live forever! So far, so good.

#2282

Posted 08 December 2010 - 10:15 PM

Thank you for offering these important "tidbits" of info - really great tech stuff!! At least to me it is - LOL!!

Thank you Bill!

Ernie

#2283

Posted 09 December 2010 - 06:20 AM

Bill did a great job of figuring out why there are any weight differences...and there's one more possibility, what actual arm I used. I don't always use the same arm that came from the motor and there is a noticeable difference between the weight of different blanks. Even though they're all steel, some are different alloys, but the weight difference is really because of the shape of the arm lams not the alloy steel that's used. I don't recall what I used for your motors, but I may not have used the original arms after stripping them.

-john

#2284

Posted 09 December 2010 - 08:29 AM

I intend to live forever! So far, so good.

#2285

Posted 09 December 2010 - 10:10 AM

-john

#2286

Posted 09 December 2010 - 12:21 PM

"heavier wire" isn't heavier in weight by volume, but "heavier guage" which is a weakness in communication.

When 110/32 was "risky" for 16ds, we were all using 36ds! THAT is why we were using those monsters. Back in 64, regularly people would point out that things like the Revell Lotus 24(25?myth?) were the only way to do a "modern F1", but on commerical tracks, Formula One was dominated by Vanwals and Lancias and other 50s F1s that had ROOM for a proper 36d! Before Arcos even!

When the 26d came out, the 16ds still didn't have the parts to live with hot winds, and the 26d with a 65/30 wind STOCK was a wonder. But within a few months, we had hemi magnets and better endbells putting down the 36ds and 26ds.

Fate

3/6/48-1/1/12

Requiescat in Pace

#2287

Posted 09 December 2010 - 01:23 PM

I don't always use the same arm that came from the motor

Hi John,

I presumed you used the original arms and stack - but you probably mentioned that you replaced the arm and I didn't catch that part - LOL!!

Thank you.

Ernie

#2288

Posted 09 December 2010 - 02:24 PM

Rocky's right too about "heavier wire", the term meaning thicker in section or gauge. You could actually produce a heavier (*by weight) arm by using "lighter gauge wire since there would be less airspace in the coil...allowing more total copper, and copper is a relatively dense/heavy metal.

-john

#2289

Posted 10 December 2010 - 07:09 PM

What dictates the voltage (minimum/maximum) that the motor is capable of running on, especially after a rewind please?

The reason I ask is that my nephew showed me a few of his motors from his RC cars called Xmod and Mini Z. The motors look similar to Falcon/TSR/Hawk motors in size but he tells me that they run on battery packs that are less than 12 volts; something like 8 volts maximum on a battery pack. He mentioned that any more voltage would cause the motor to fail.

Is there any reason why these motors would not work on a slot car and vice versa.

I'd like to hear perspectives on this please.

Thank you.

Ernie

#2290

Posted 10 December 2010 - 08:38 PM

It's very simple actually...the more voltage the shorter the life. You can run motors that were made to "live" a fairly good life at 12V on 36V for short bursts and they may hold up fine. Say you have a motor that would normally live for 4 hours of track time at 12V, if you run that motor on 13+V it may only last for 2 1/2 hours. Your nephew's "8V" motors could probably do fine at 12V for a short period of time, they just wouldn't last very long. A rewind is no more apt to fail because of voltage than any other motor...it's just that not many people will rewind a motor to run slower than it did stock

This leads to another sort of related subject, that being that tracks often run at higher voltages...I guess to make the motors run faster and to add a little more excitement. However, this will shorten the life of the motors and in any case, as long as everyone runs at the same voltage, the racing will still be fair at lower voltages (12V nominal). If the motors being run aren't fast enough at 12V, you could just run motors that ARE fast enough at 12V. So I don't quite get why this is done...but I don't race so I'm probably missing something here.

-john

#2291

Posted 11 December 2010 - 01:03 AM

I think it is more than that. I believe the 8v motors in the Atomic/RC cars are wound with less turns of smaller wire. This makes the motor faster with less amp draw due to the small diameter of the arm wire. But once you put more amps and voltage on the motor it blows up because the small diameter wire can't handle the amperage (been there, done that). The RC guys have to worry about current draw much more than we do. They play the game of how hot they can wind the car and still have battery power at the end of their race. We don't have to worry about amp draw on our motors as we simply take everything we can get. So our hot arms are wound with hotter winds with larger wire in general. I'm sure TonyP can correct me if I'm wrong!

#2292

Posted 11 December 2010 - 08:08 AM

-john

#2293

Posted 11 December 2010 - 10:19 AM

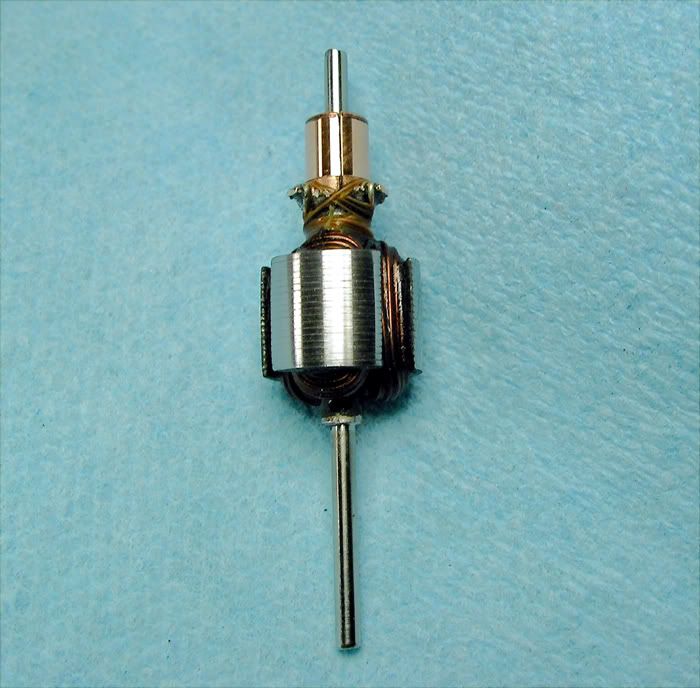

This is sort of like the eurosport arms, except for the arm diameter and the wire gauge. It even might work in a eurosport setup if the OD was ground down appropriately...although I don't know that the wind is at all appropriate. I'm hoping that the neos will be up to this thing, but if not...it should make a dandy itty bitty drag arm.

-john

#2294

Posted 11 December 2010 - 12:03 PM

It's exciting to see the different - if I may say "experimental" rewinds! Are your "strapnuts" that much more powerful than the "walnuts" please?

Thank you.

Ernie

#2295

Posted 11 December 2010 - 12:08 PM

Are your "strapnuts" that much more powerful than the "walnuts" please?

...depends on the wind, but generally as... or more powerful at an even lighter weight. The arm above should be an "upper limit" (or beyond) motor when done. The only problem is that the danged neos suck up little bits of steel from all over my zipcode. I keep cleaning off my workbench surface (glass) and ten minutes later there's all kinds of stuff clinging to the motors. I never had that problem with Mabuchis

-john

#2296

Posted 11 December 2010 - 01:22 PM

Hi Ernie,

...depends on the wind, but generally as... or more powerful at an even lighter weight. The arm above should be an "upper limit" (or beyond) motor when done. The only problem is that the danged neos suck up little bits of steel from all over my zipcode. I keep cleaning off my workbench surface (glass) and ten minutes later there's all kinds of stuff clinging to the motors. I never had that problem with Mabuchis

-john

LOL John,

I have that problem even with reg ceramic motors, and I keep my bench pretty clean. All this time I thought it was just me

#2297

Posted 11 December 2010 - 03:11 PM

It's not just you guys i am working on a high performance 13d rebuild i used TSR magnets and i made the mistake of glueing them in with epoxy before i cut the can down i had to use duct tape to remove most of the metal dust from the can that was 3 days ago and i am still finding little bits of metal stuck to the can.

#2298

Posted 11 December 2010 - 03:22 PM

-john

#2299

Posted 11 December 2010 - 04:02 PM

FWW- I have an air compressor that puts out 120 psi. I use a needle air blower at full boar, and it cleans every bit of that crap out of the can and magnets.

Just make darn sure your magnets are glued in real good !!

I also do this just prior to installing the arm.

Vic

#2300

Posted 11 December 2010 - 05:00 PM

This topic is locked

This topic is locked