#2251

Posted 01 December 2010 - 05:18 PM

John is the "motor pusher" and he pushes some real nice "stuff; and it seems I need more and more - LOL!! I really enjoy this thread with all the education and shared info.

Thank you John and everyone!

Ernie

#2252

Posted 01 December 2010 - 08:32 PM

If you come to this thread a few or more times daily - then I would label yourself a "motorholic"! My name is Ernie and I'm a motorholic LOL!!!

John is the "motor pusher" and he pushes some real nice "stuff; and it seems I need more and more - LOL!! I really enjoy this thread with all the education and shared info.

Thank you John and everyone!

Ernie

Tha'ts right Ernie, Its all John's damn fault !!!!!!!

I'm seeking help for my problem

#2253

Posted 02 December 2010 - 05:46 PM

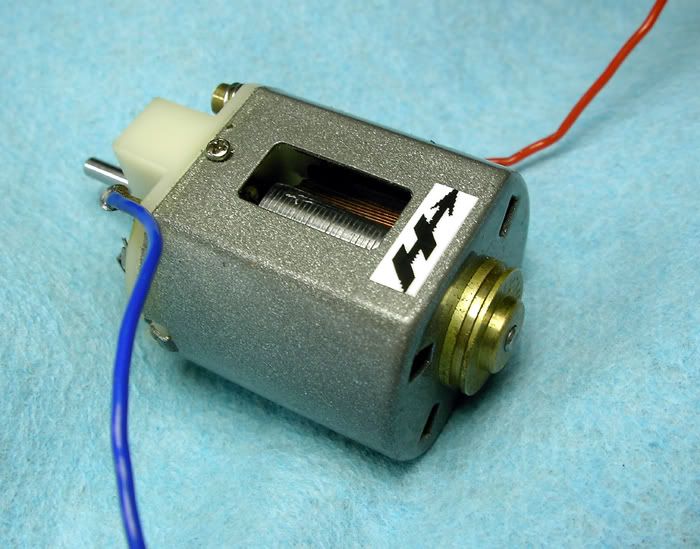

Started work on some FT36d Mabuchis for "MantaRay". He wanted an arm installed in a nice Champion 36D can ...but the arm he sent just wouldn't go in there. So next up was to rewind an arm to fit, not too hot...just solid and smooth, so I did him a #29 wind with a Kirkwood com (carefully drilled-out to fit the larger shaft and trued afterwards).

Then on to the setup to get it all together:

Runs super smooth and is a step up performance-wise too. Best of all, it barely gets warm!

-john

#2254

Posted 02 December 2010 - 10:23 PM

Nice work on the 36D 29 gauge seems to work well on these big motors, did you replace the gimbal bearing those things are worthless for any kind of performance build.

#2255

Posted 03 December 2010 - 06:39 AM

did you replace the gimbal bearing those things are worthless for any kind of performance build

I have in the past replaced them with either fixed bushings or bearings...but only when necessary. People have had me replace them (usually with bearings) on motors that are fine also just to have a rebuiilt motor start off with fresh hardware. When they are a tight fit to the shaft and are solidly held in place by the can fixture, I think they're fine. I think it's a bigger problem when people let them run dry, but because they're solid brass instead of oilite they last a long time with just a small drop of oil. I think the concept is a good one, as the bushing not only can account for misalignment...but provides a sort of "shock absorber" at the can end. Definitely not for real high rev motors, but the 36D rarely gets into that territory...for long

-john

#2256

Posted 04 December 2010 - 12:52 AM

I hawe a problem.. when i shorten the can of my mura engine the arm will be too long.... plan too by a G12 or cobalt 12 arm

its nott the arm it self only the distance of the arm sitting of the opposit side of the conduktor ....the distance is lokking like a brass pipe om the enginn axel

Can i gently cut it off so i vill hawe closer betveen the bearing surfecis of the arm....

hope you understand my problem...

Bdw nice work om thes enginse ...they looks super

Joakim Forsman

#2257

Posted 04 December 2010 - 07:12 AM

The part you're speaking about at the end of the armature shaft is called the "tail spacer" and it can easily be shortened with a Magnehone Armature Tool. These are usually used to just remove a little material from the end of the tail spacer and commutator to get them "true, flat and perpendicular or square to the shaft by spinning them with your fingers while holding the armature. They have a diamond abrasive coating on them to remove a little material. If you chuck the armature in a Dremel tool or similar and then spin the armature for a few seconds while holding the magnehone against the tail spacer, clean the tool and then do it again until it's as short as you want it...it will eventually remove enough material. You can also make something like the magnehone with the little Dremel sanding discs attached to a block that has been drilled out for the 2mm armature shaft. The whole idea here is to do the work without damaging the armature shaft. Some armature shafts are "soft steel" and some are true hardened drill blanks...but either can be damaged and then the armature won't run well in the bushing/bearings and any roughness on the armature shaft might even damage the bushings or bearings by causing them to prematurely wear out.

-john

#2258

Posted 04 December 2010 - 10:55 AM

I haven't wound anything with it yet but thought I would pass the information along.

http://www.techfixx.com/

Kelly

#2259

Posted 04 December 2010 - 02:38 PM

I got motivated today to tear into FT36D #2 for Manta Ray so I went for the gusto. I again drilled out a vintage Kirkwood commutator because I wanted to go a little hotter on this one...not "flame thrower" hotter, but what I consider to be near the max for even casual running. Removing the fiber end insulators and insulating the stack directly bought me some room (without sacrificing any actual laminations) and I gave this one a little bit more timing advance. So after prepping the arm, I rolled out some #30 awg onto a second spool as I decided to do a double wind (not one layer on the other, but two wires at the same time) because they just seem to work really well on these old motors. It was relatively easy to get the number of double turns on there that I was after and the wind came out really neat with the coils being pretty compact. The arm meters at somewhere around .3 ohm or slightly more which is about where I expected it to land. I did more epoxy on this arm than normal for a little bit of that "vintage look"...as if people really look at armatures anymore

The setup is an old FT36D K&B (my favorite when I was a kid!) which may be why I went the extra mile on the arm.

This bad boy sounds just great...even with the stock total garbage magnets. Super smooth and winds like nobody's business...now THIS is what a FT36D should run like!

-john

#2260

Posted 04 December 2010 - 02:55 PM

#2261

Posted 04 December 2010 - 03:36 PM

Nice work John, a double rewind i did a 29-30 once, they do seam to run a little cooler than a single but i still haven't figured out why.

John i am still thinking about a new power supply the one you suggested looks good but is a little large, would 6 amps be enough to power these motors because a 6 amp Mastech is a lot smaller and about $20.00 cheaper and i am shore a little cheaper to ship.

#2262

Posted 04 December 2010 - 03:56 PM

I have wound many arms that will draw more than 6A for a short while, so I would be going for something that could do at least 10A. I think it's always better to have lots of "headroom" (the side of me that does recording engineering sometimes interferes with the side that does slot car motors) on any device. Then again, the side of me that works as a carpenter just HATES the idea of buying anything that I might have to replace because I should have gotten something better...buy a good tool once or a lesser tool several times. I am NOT an electrical engineer or any kind of expert on power supplies and would simply ask around right here on SlotBlog for other people's experiences and then after seeing some sort of consensus make a purchase decision. More than once, I've been steered right by the advice of SlotBloggers.

-john

#2263

Posted 04 December 2010 - 04:45 PM

Thanks that's info i needed if you have built motors that draw 6 amps than i will need the 10 amp supply, as the saying goes better to have it and not need it than to need it and not have it.

#2264

Posted 04 December 2010 - 06:09 PM

Thanks again

11/4/49-1/23/15

Requiescat in Pace

#2265

Posted 04 December 2010 - 06:38 PM

.They don't call me MantaRay for nothin'...........I'll find a place for it..........

-john

#2266

Posted 07 December 2010 - 08:01 PM

The motor got the complete tear-down treatment...stripped, drilled for endbell retaining screws, new can bushing, better magnets (I think Muras), Tradeship endbell, post protectors and a nice new shiny coat of gold metallic paint. It runs strong, smooth and sweet...not getting at all "hot". I believe this would be a good wind for a period type car that would be raced. It sure feels like it!

-john

#2267

Posted 07 December 2010 - 09:10 PM

Mike Katz

Scratchbuilts forever!!

#2268

Posted 07 December 2010 - 09:35 PM

-john

#2269

Posted 08 December 2010 - 02:14 AM

Ernie

#2270

Posted 08 December 2010 - 06:20 AM

-john

#2271

Posted 08 December 2010 - 06:40 AM

For it's time the 22 wasn't really all that anemic, and did very well in its intended cars. I still use these motors in a number of 1/32 cars and they perform very well on the comparatively short tracks here in Europe. And I've also seen some of the Russkit Black Widows, with the twin 22s, run pretty well on shorter tracks.

Have you tried rewinding one of these stock 22s? I wonder what kind of wind it would handle... (probably about an 80 x 32 at the most, I would guess).

Don

PS/ remind me, what bushings are you using in the can?

#2272

Posted 08 December 2010 - 06:49 AM

Of course you're absolutamente correctamundo (as we say in NY)

The can bushing is just the endbell bushing from this very motor's original endbell. Drilling out the can's original blind bushing leaves a perfect hole for the endbell bushing and then the arm can easily be shimmed to center it in the field and it's also much easier to oil the thing.

-john

#2273

Posted 08 December 2010 - 07:05 AM

The can bushing is just the endbell bushing from this very motor's original endbell. Drilling out the can's original blind bushing leaves a perfect hole for the endbell bushing and then the arm can easily be shimmed to center it in the field and it's also much easier to oil the thing.

-john

Very clever Mr. Havlicek! Now, why didn't I think of that??? I generally keep the original endbell, but probably have dozens of these bushings floating around, so to speak...

Just acquired a lot of motor parts, so will look through there to see what mysteries they hold...

Don

#2274

Posted 08 December 2010 - 07:12 AM

-john

#2275

Posted 08 December 2010 - 12:40 PM

I think there was an article about it.

Initially with the SP500/Russkit22 motors which came with either a 36 or 34 wind, we shaved down the front of the endbell and sleeved the brush carrier. I think that one of the midwest guys told me about that one in the day. But you are correct, we didn't get hotter than a 110/32 to live.

Fate

3/6/48-1/1/12

Requiescat in Pace

This topic is locked

This topic is locked