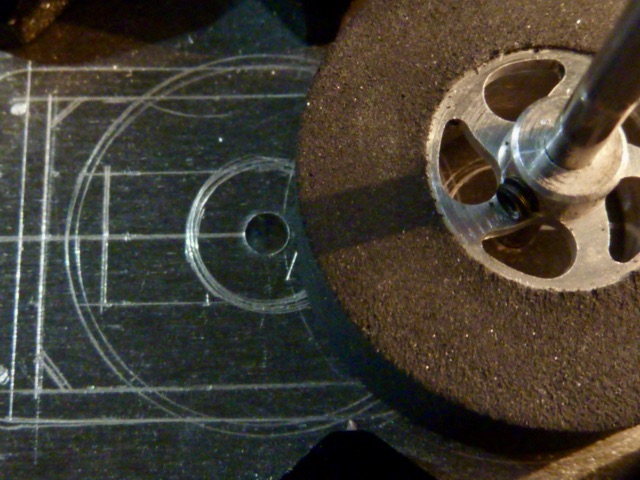

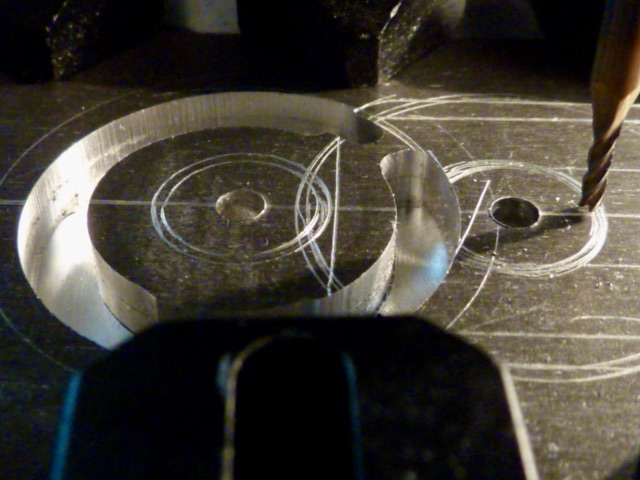

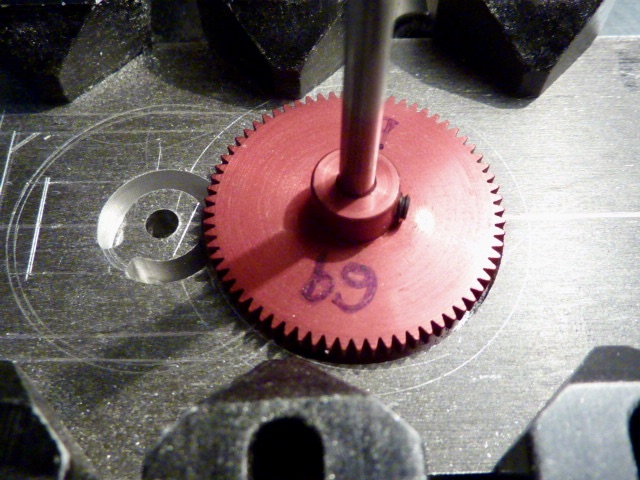

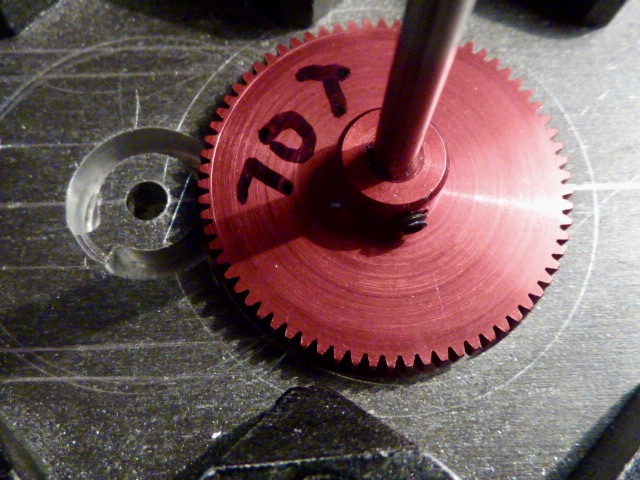

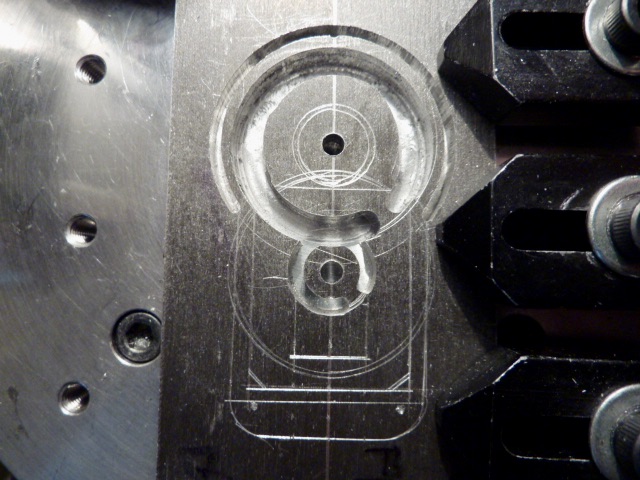

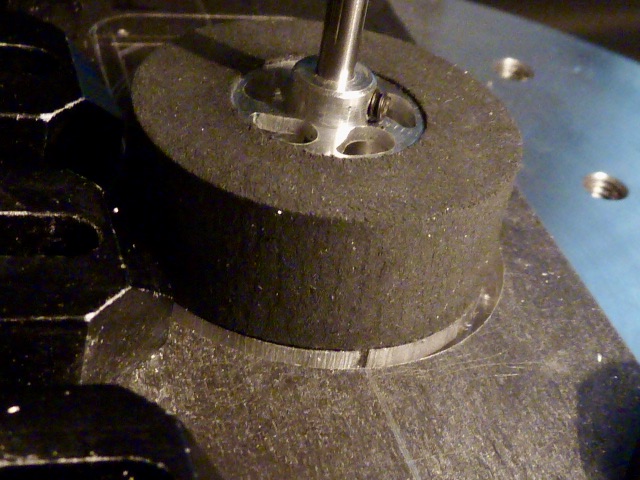

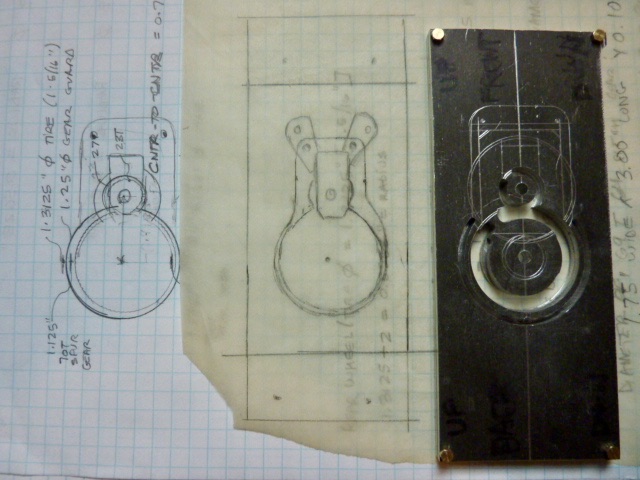

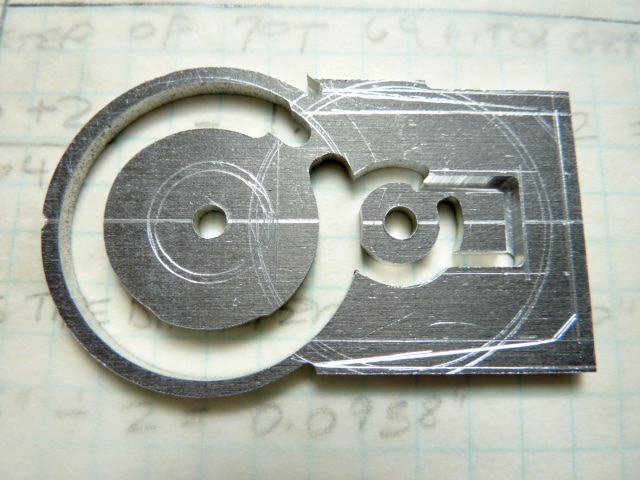

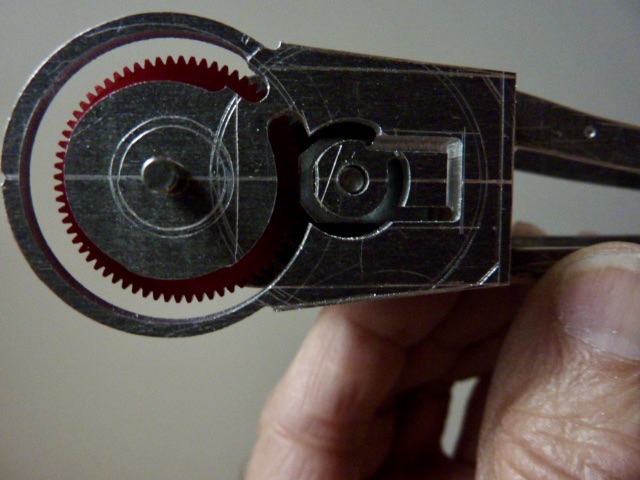

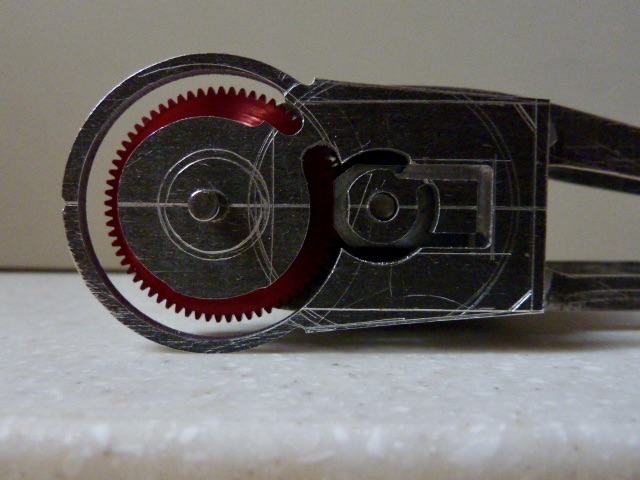

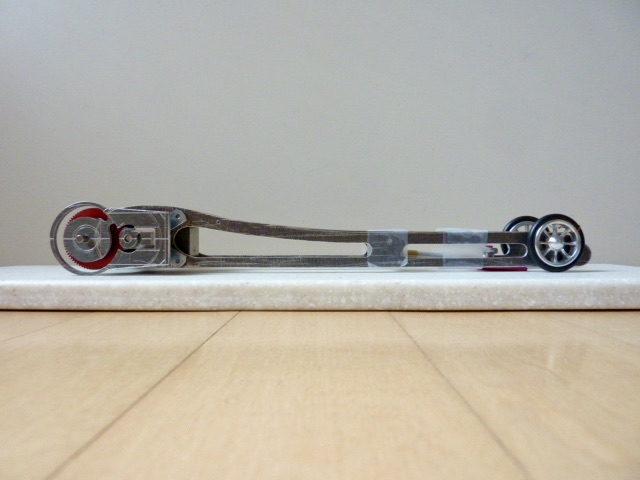

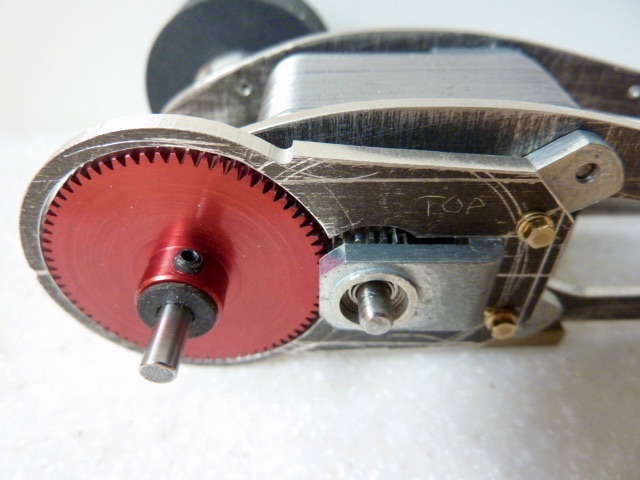

The outside scribed circle on the spur gear or rear axle hole represents a 1-5/16" diameter wheel/ tire.

Per 1966 dragster class rules, the maximum allowed tire diameter is 1-3/8", so a 1-5/16" diameter tire is a reasonable size to base the Husting and Maldonado gear guard size on.

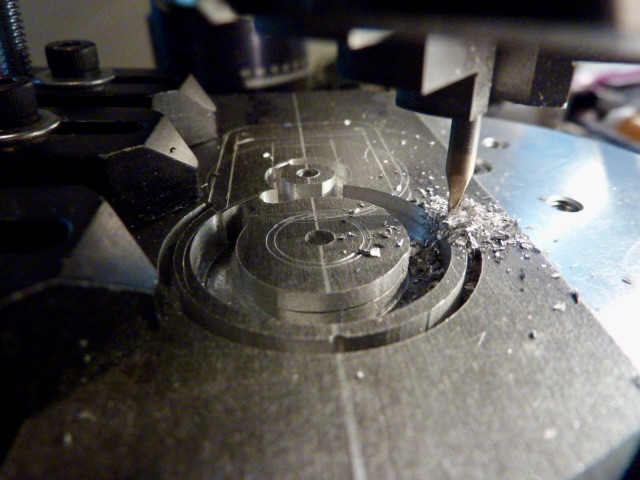

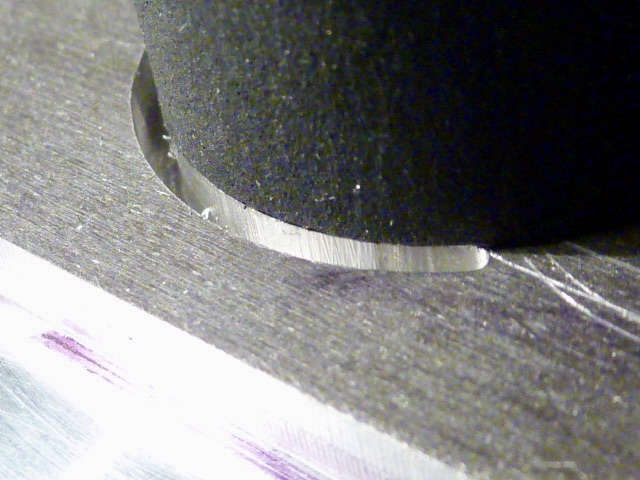

The gear guards' outer spur gear circumference/ diameter must be less than 1-5/16" or the rear end of the car will bottom out on the track's surface.

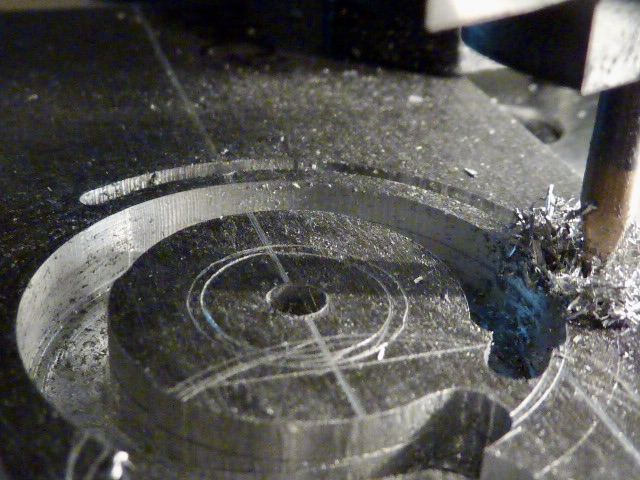

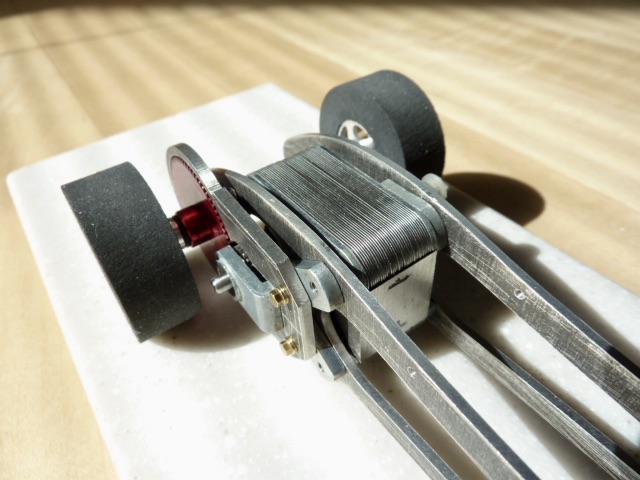

The gear guards' "ring" of 0.10" thick magnesium material around the 69T gear is extremely slender.