I found it. Thanks for pointing me in the correct direction. ![]()

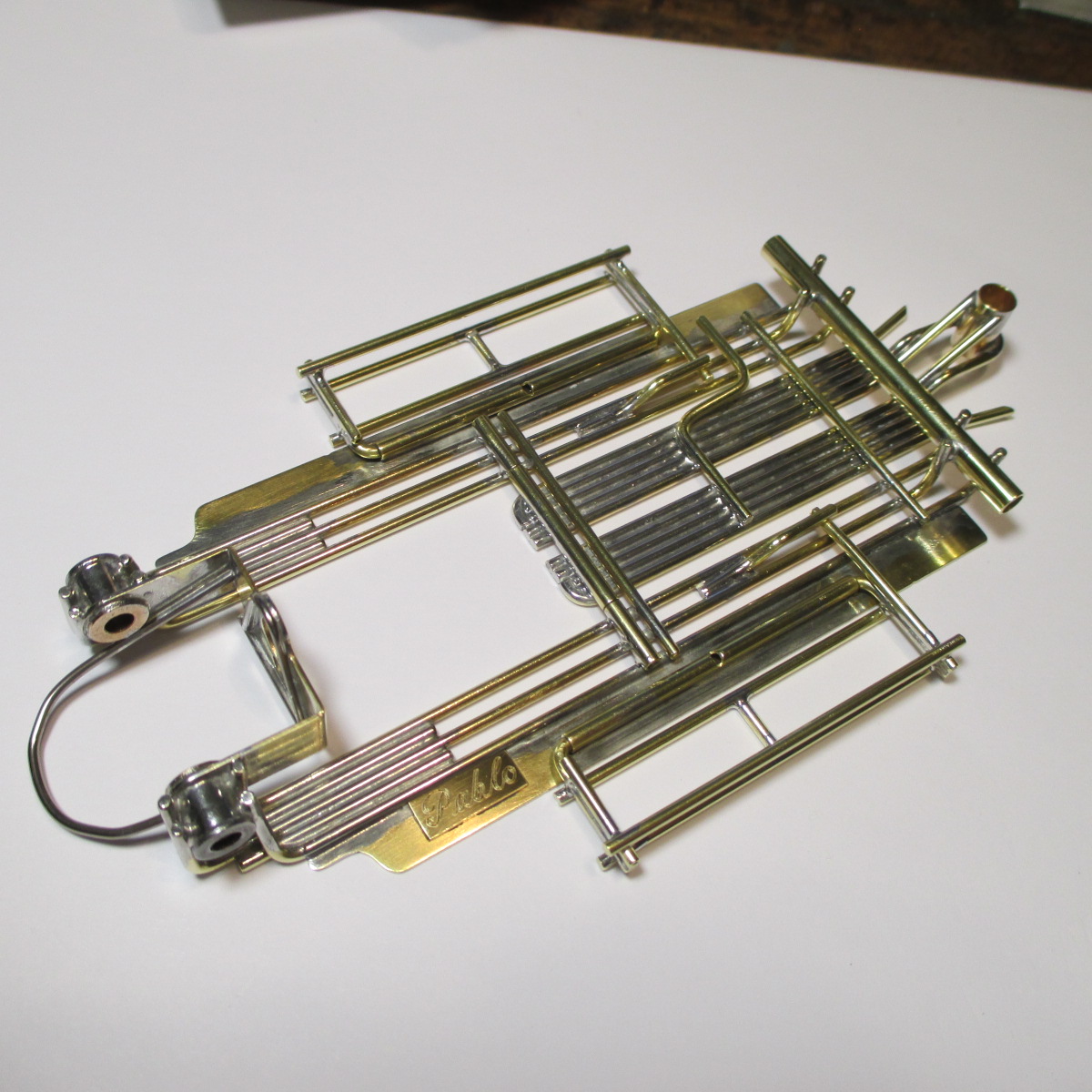

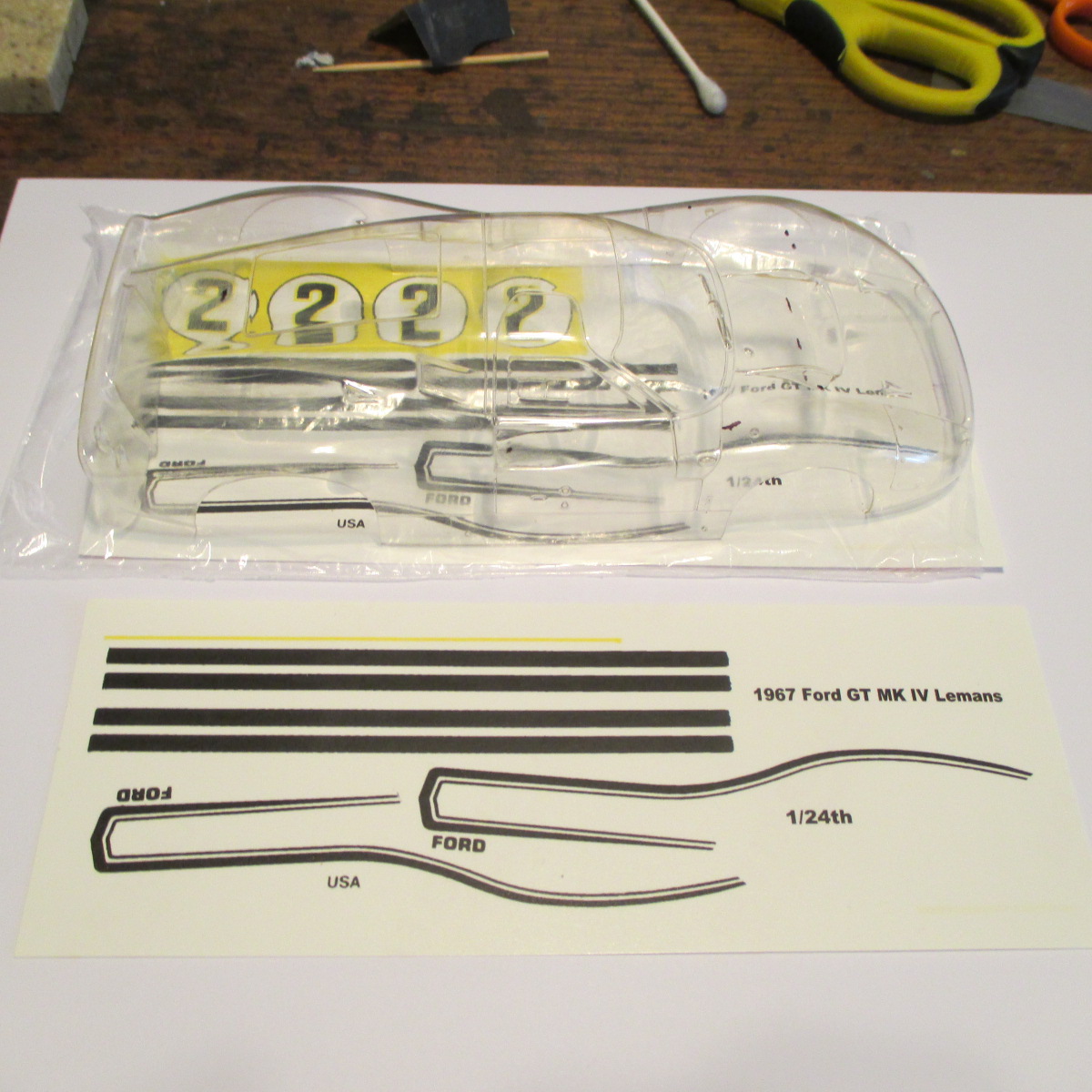

Ford Mk IV GT40 built by Pablo

#101

Posted 15 March 2021 - 01:03 AM

#103

Posted 15 March 2021 - 08:47 PM

![]()

![]()

- Pablo likes this

#104

Posted 16 March 2021 - 12:20 AM

Shiny!

Remember the Steube bar! (ask Raisin)

SUPPORT YOUR LOCAL RACEWAY!!

"The denial of denial is the first sign of denial." Hank, from Corner Gas

"Death before disco!" Wanda from Corner Gas

Nelson Swanberg 5618

Peace be with all of us and good racing for the rest of us.

Have controller. Will travel. Slot Car Heaven

#105

Posted 16 March 2021 - 03:59 AM

great attention to detail, pablo! nicely done!

- Pablo likes this

#106

Posted 17 March 2021 - 06:30 PM

Thank you, gentlemen ![]()

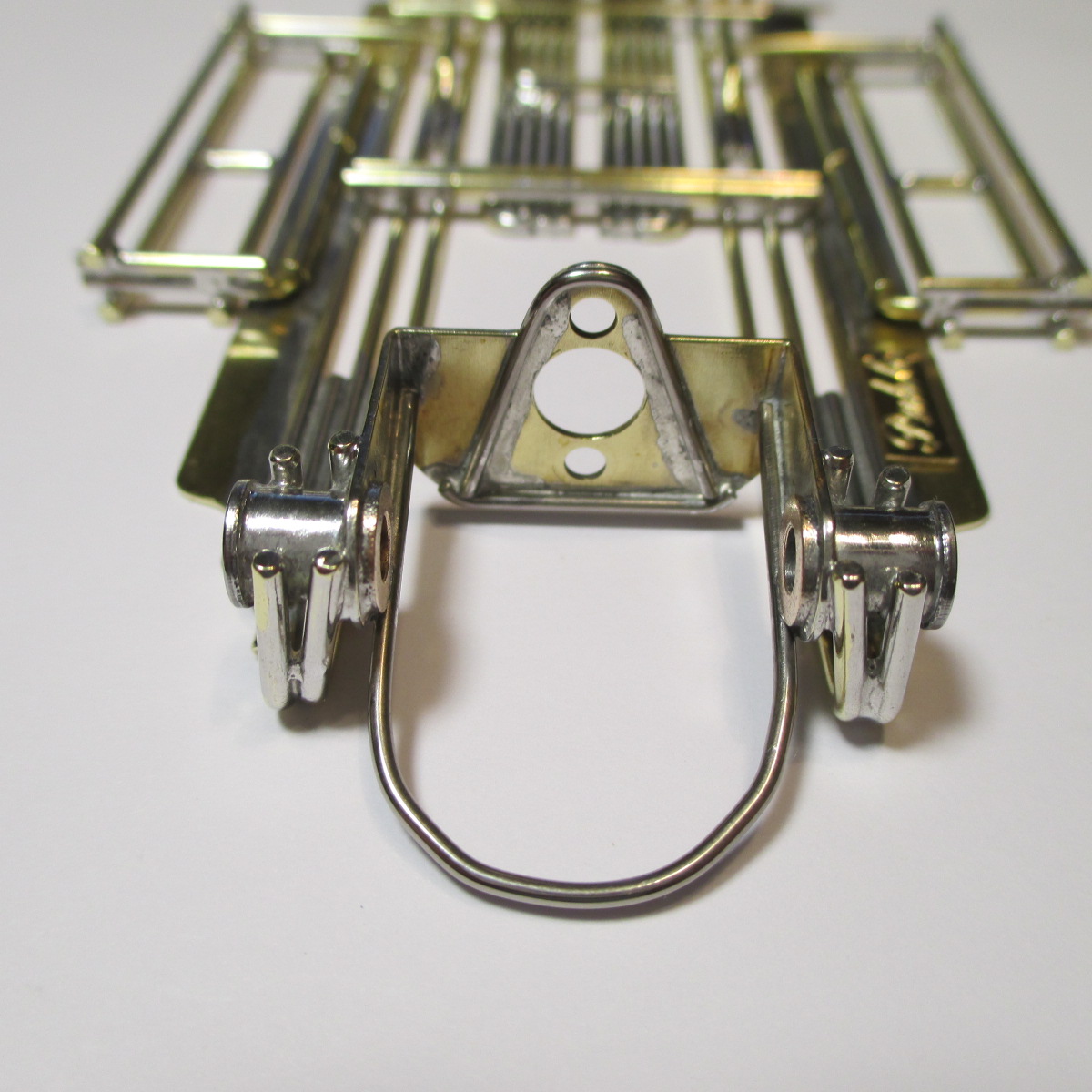

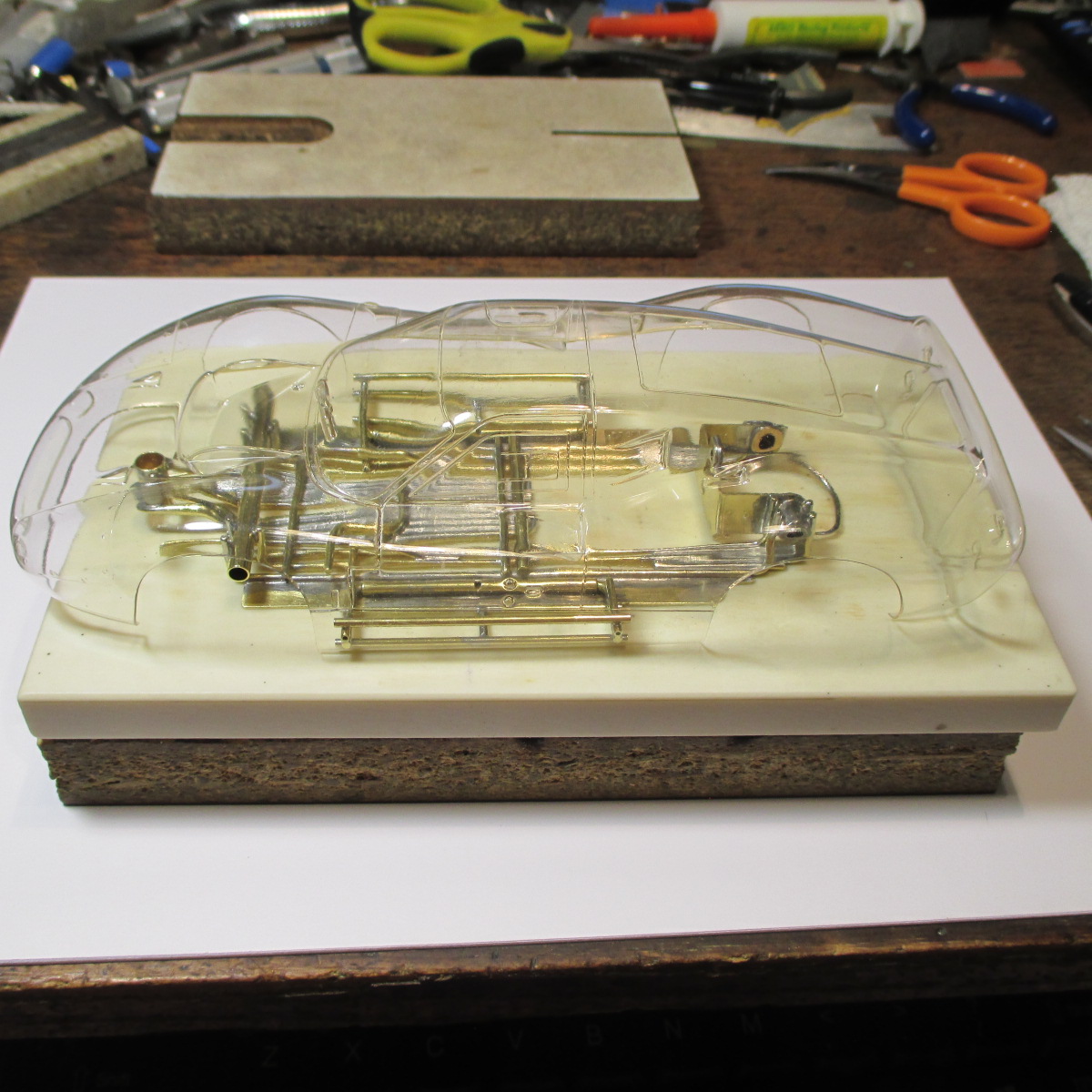

Standard post-tumble procedure - chassis sprayed with WD-40 and all hinge points oiled, especially the rear axle bushings. Just like cleaning a military weapon - you clean it, bring it to the Gunner's Mate, he puts his pinkie finger up in there and shows you dirt. Back to the cleaning bench ![]()

In this case, pipe cleaners and Q-Tips need to come back pure until they pass muster. Even the pin tubes are clean and lubed. Body is done soaking up UV rays, and placed over the chassis for a fit check. Looks very nice. Obviously, the body bottoms can be trimmed up a little and the pin mounts may need some horizontal trimming to allow the tilt mounts to sit at ground zero without being forced.

That's it for today

- Alchemist and Peter Horvath like this

Paul Wolcott

#107

Posted 18 March 2021 - 02:44 PM

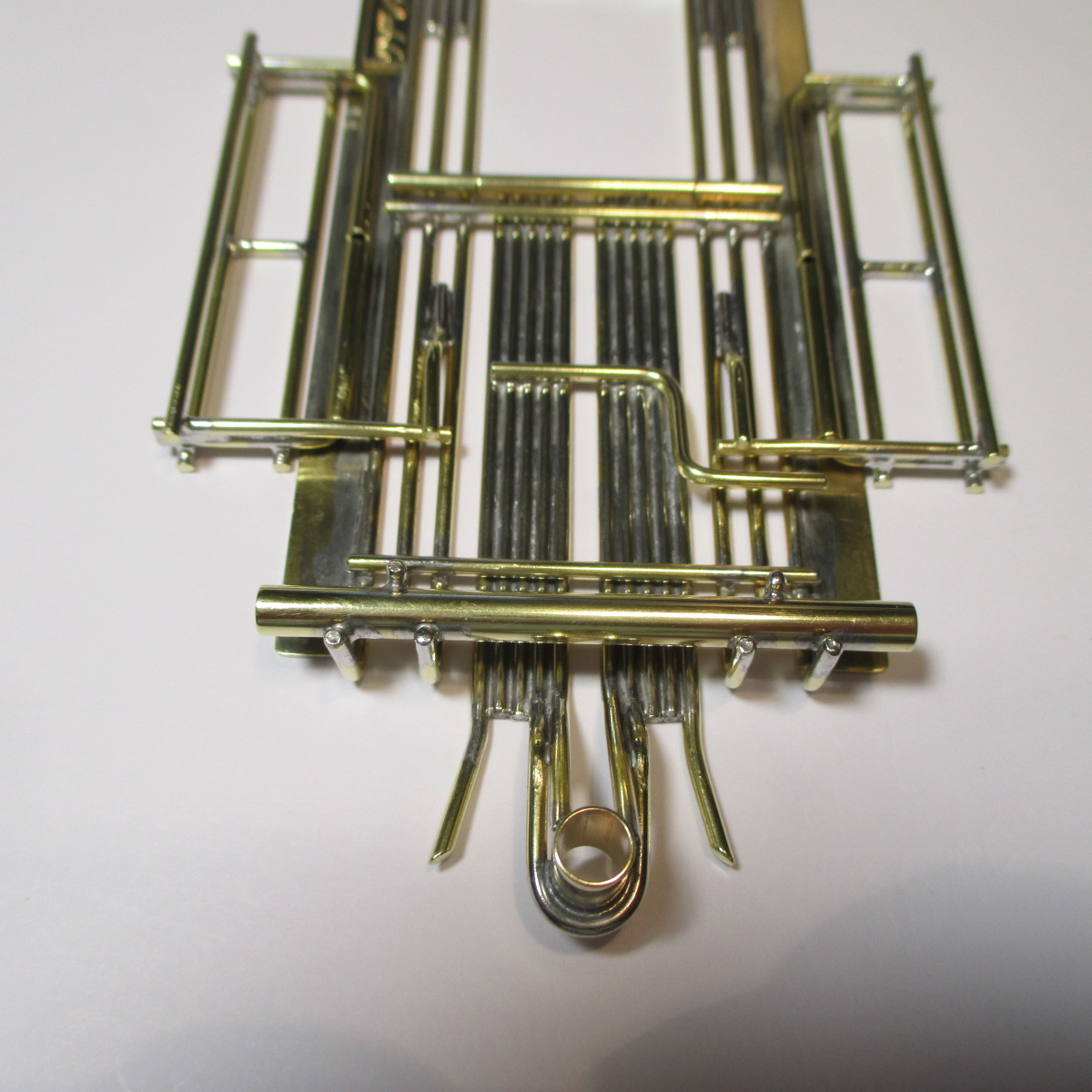

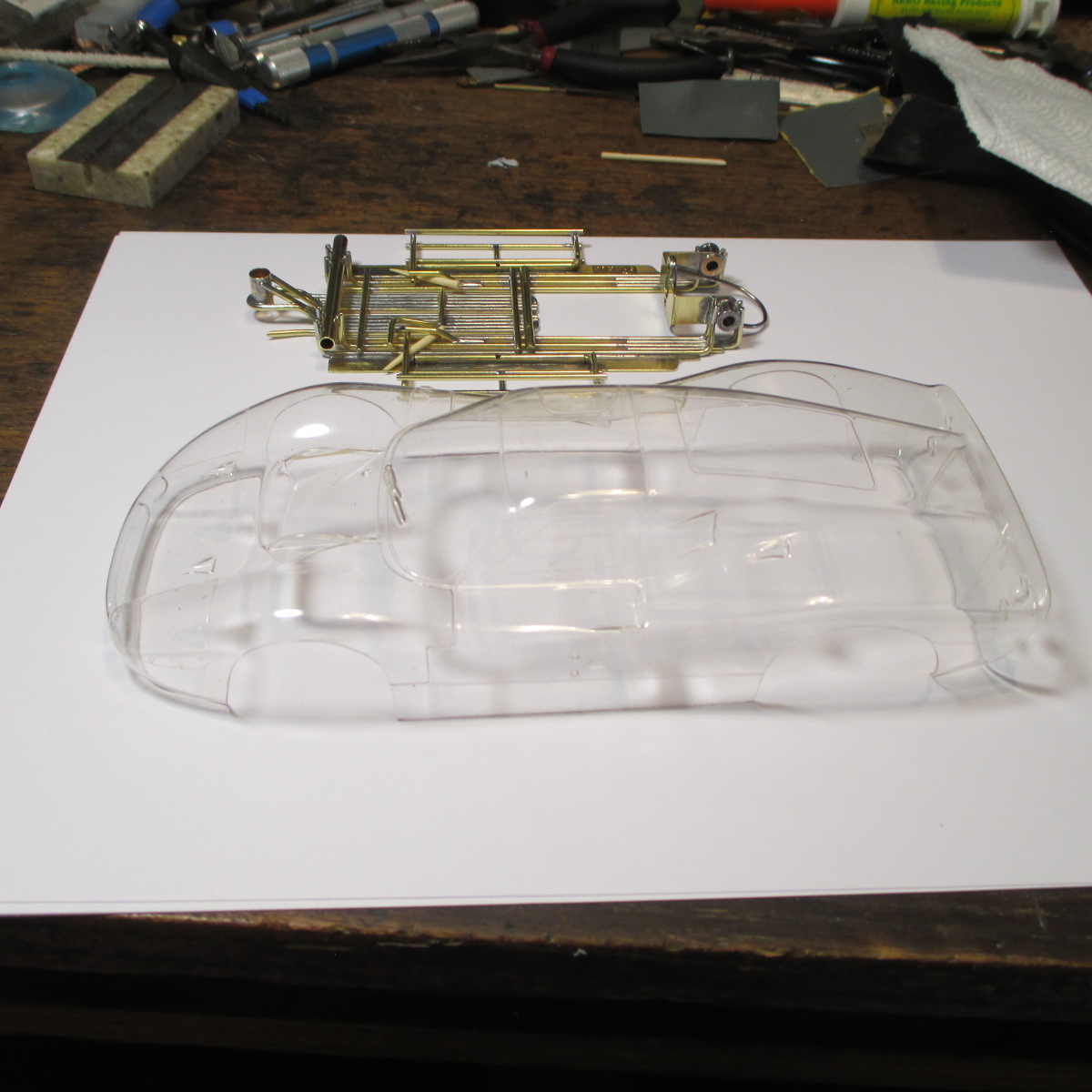

Body trimming and pinning - slow and careful is the only way to go. I locked the tilting pans up, using toothpicks. The 53-ish year old rare vintage body is in amazingly great condition. It's thick butyrate; mikes about 25 thou all round.

Whoever did the rough trimming did a super job; all I need to do is finish it. I snipped, sliced, measured, sanded, and twisted (yes it had a slight curl to it) the body until it started to behave. The horizontal line that runs wheelwell to wheelwell on the skirts is exactly true to the real car correct stance ![]()

Starting to look a little lower now. and the body takes a rest. I need a sandwich and a nap ![]()

- Tex, Peter Horvath, Rotorranch and 1 other like this

Paul Wolcott

#108

Posted 18 March 2021 - 07:29 PM

It looks like a Lancer body to me and they were always trimmed at the factory. It came from a time when they cared to make a great product.

Great body for your great chassis. ![]()

- Pablo likes this

#109

Posted 18 March 2021 - 08:18 PM

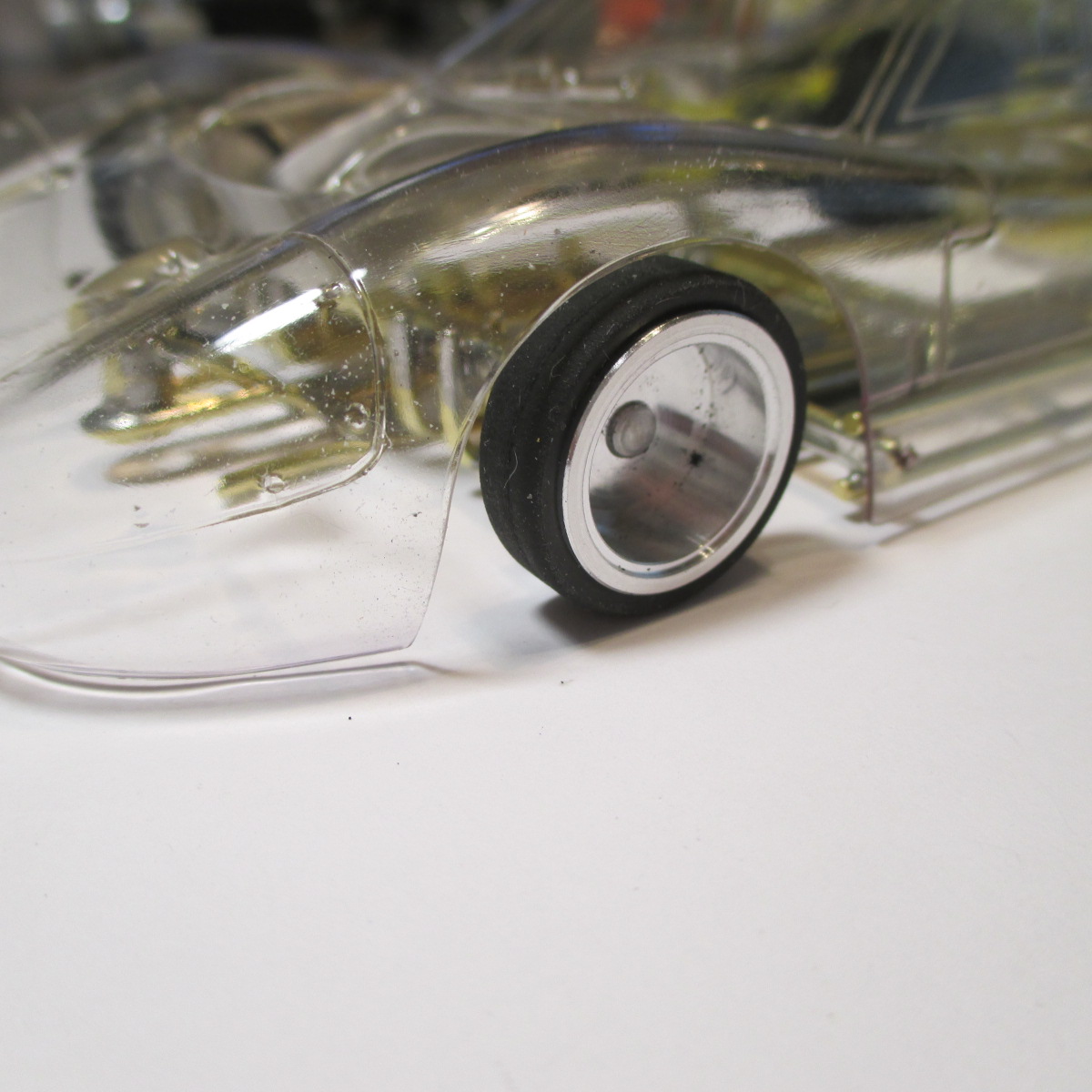

Thanks Martin. ![]() Trimmed at the factory? Aha, that explains the clean cut lines. Also explains why they carved it for a big car with lots of clearance and huge wheels. I lowered it about 1/16". Any more than that and the details would start "getting lost"

Trimmed at the factory? Aha, that explains the clean cut lines. Also explains why they carved it for a big car with lots of clearance and huge wheels. I lowered it about 1/16". Any more than that and the details would start "getting lost" ![]()

I agree, the Ursaner chassis with it's pan tilt style works well with curved body skirts ![]()

Paul Wolcott

#110

Posted 18 March 2021 - 11:17 PM

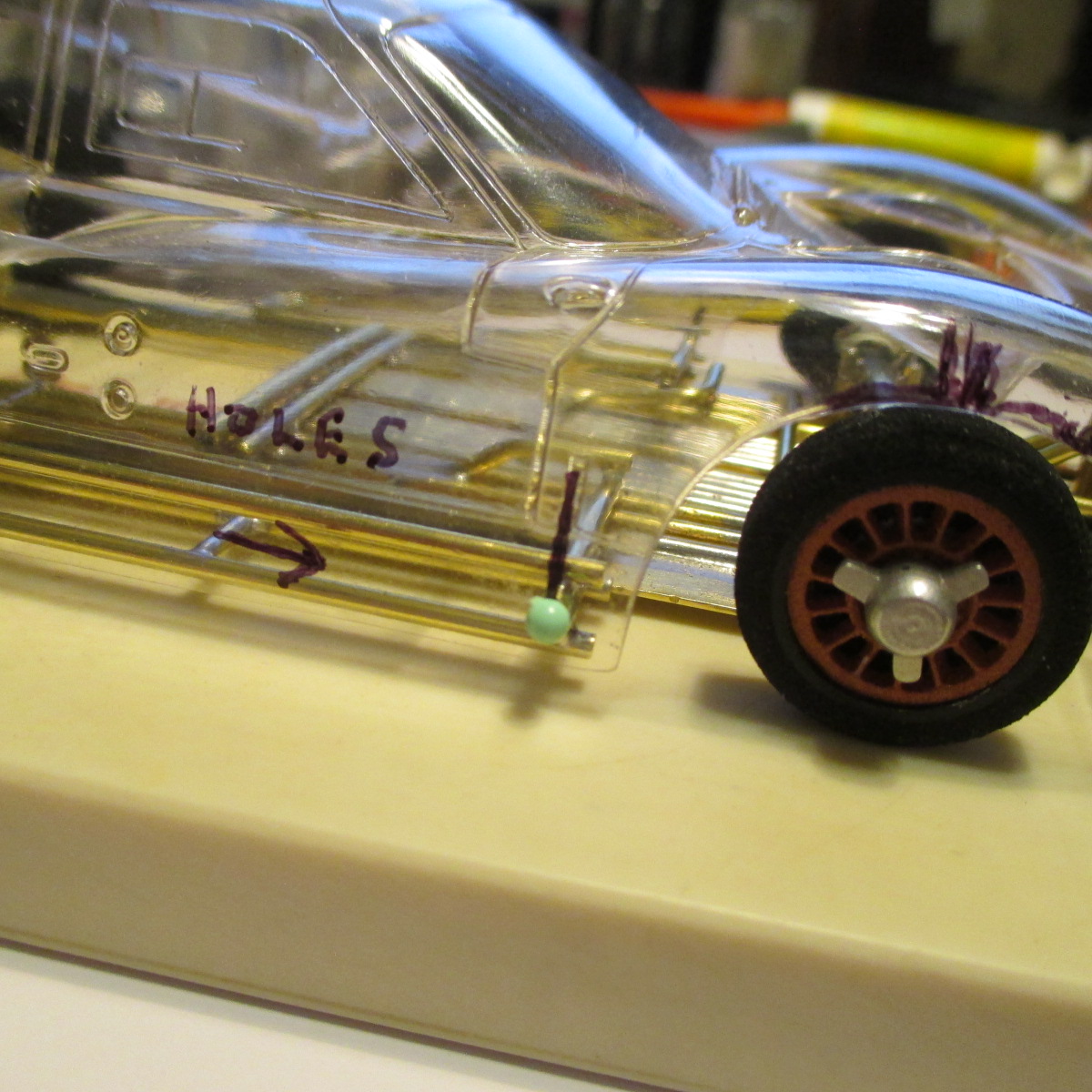

I used my trick of using thin dress-making pins to make preliminary holes. Both starboard side holes need to be encouraged to move forward just a hair. I got lucky on the up/down - it's perfect.

When I harpoon the holes, the port sides will get punched with a rear bias, and the fronts with a forward bias. Also the top of the right front wheelwell needs a slight trim with the Dremel sanding arbor ![]()

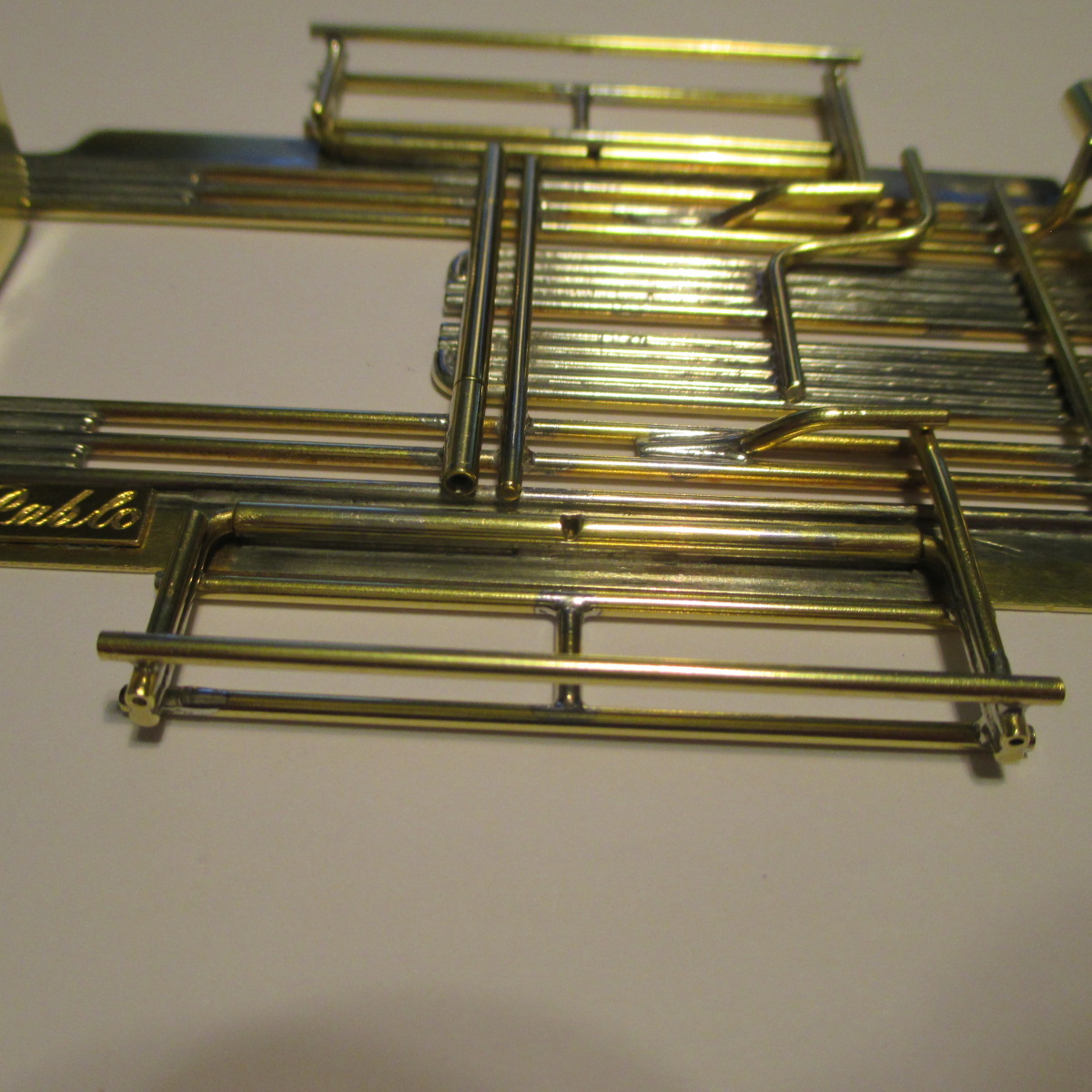

I need to narrow the pin tubes where they meet the curved body skirts just a hair. As it is, the body is grabbing and pinching the chassis. A simple matter of narrowing them about .032

- Alchemist and Peter Horvath like this

Paul Wolcott

#111

Posted 19 March 2021 - 01:32 AM

Would be best to narrow the front track a bit and save that factory arch? ![]()

#112

Posted 19 March 2021 - 10:21 AM

The front wheels haven't even been set yet. I put them wide just temporarily to better see where to punch the pins.

Don't misinterpret lots of Sharpie marks for an intention to remove a lot of material. It just needs a hair in one little spot.

Thanks for checking, though ![]()

Paul Wolcott

#113

Posted 19 March 2021 - 11:27 AM

Got it, and then I thought about intentional wheel slop, side to side. How much do you give the front axle and does it make a difference?

#114

Posted 19 March 2021 - 12:09 PM

Good question. Depends on which ruleset, which chassis, which body, etc. It makes an improvement on cars with hard fronts, especially on vintage GP cars. Some rules allowed 1/8 per side, 1/4" total slop ![]() But most only allowed it on GP cars.

But most only allowed it on GP cars.

This car has hard foam fronts and I don't think I want them moving too much. We shall see. The tubes are cut at 2" so the owner can tune it with spacers if he wants

Paul Wolcott

#116

Posted 20 March 2021 - 08:04 PM

Through all this I've been working with a nagging "body pinch" situation where the tilting mounts won't drop to the stops without force. This is normally caused by the chassis being a little too wide for the body, and usually is a simple fix.

Not so here. It's more complicated than that - the old body is thick and it has a mind of it's own. Through a combination of pin tube narrowing, skirt tweaking, pin manipulation, and enlarging the body holes to .039" using my mini-twist drill set, she finally drops down properly when lifted. I do not want to be fighting it once the decals and yellow paint are on LOL ![]()

Now I can proceed onward ![]()

- Tex, Slot Car Rod, Peter Horvath and 1 other like this

Paul Wolcott

#117

Posted 21 March 2021 - 07:47 PM

As long as I keep getting the occasional PM saying "thanks for your detailed explanations" I will continue my "style". As long as the experienced guys don't think I'm being condescending, we are cool, eh?

Body separated from chassis. Continuing my "I don't want to be fighting the body once the decals and paint are on" theory, I harpooned and drilled out .063" holes for the Warmack mirror shafts. Made slight trim cuts to the Noose interior, and some Sharpie marks outside to make alignment easy

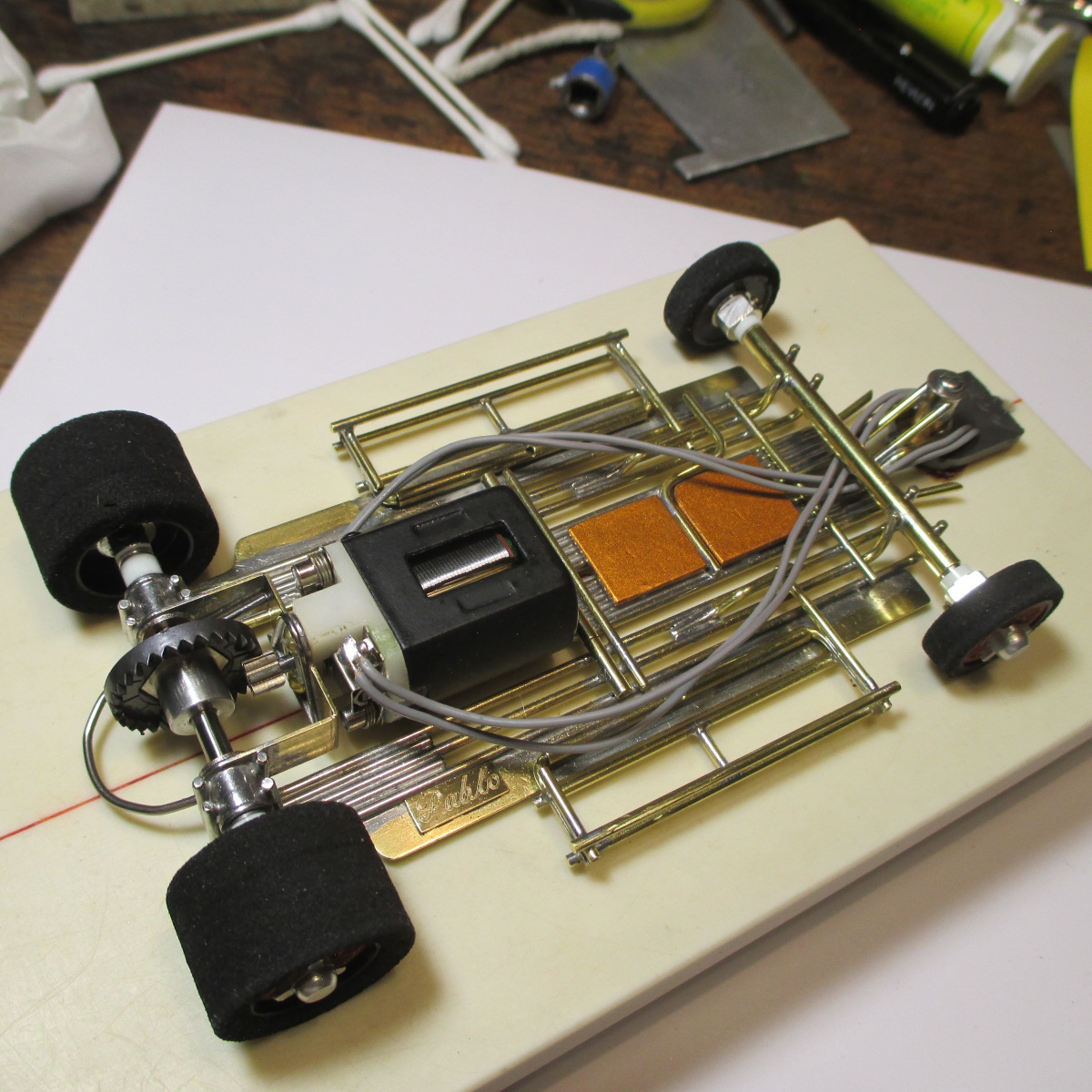

I did not use lead chunks on my first Ursaner replica - I left it as an option to be added after track testing, if needed. The Lotus 40 body I used was only .010. This body is bigger and heavier at .020 +. So I feel it needs lead chunks like Howie used on his original race car.

I cut 2 rectangles of .063 lead to size, primed, painted with VHT copper, cooked at 200 for 1 hour. I didn't need hi-temp - but the chemical resistance property is only activated by baking. Attached to drop arm with JB Weld. Like my Urologist told me decades ago - "Paul, this is irreversible" LOL

- Tex, Peter Horvath and MattD like this

Paul Wolcott

#118

Posted 22 March 2021 - 11:51 AM

Decals - I keep thinking they are so long and swoopy, my usual inside installation would turn into a goat rodeo. So I did the smart thing and decided decals will be outside. I ordered Micro Sol and Micro Set

Can anybody please verify they are safe for butyrate? Pretty sure they are, but just checking .......

- Peter Horvath and Greg Erskine like this

Paul Wolcott

#119

Posted 22 March 2021 - 11:59 AM

Hi Pablo,

I use some Micro Set on an old T-shirt to clean the outside of the body where the decal goes. I also use a bit on the decal before I slide it off the backing and onto the body. The stuff will etch the plastic over time if you leave it puddled on the body so wipe off the excess after you are done placing the decal.

You also might want to check how those decals behave by experimenting with the "1967 Ford....." lettering. If they are so thin you have trouble with them you could try a light coat of Testors lacquer.

- Pablo likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#120

Posted 23 March 2021 - 07:56 PM

Thanks Rick, I will do that test ![]()

Assembly was pretty smooth, but some improvements are needed:

-Flag needs more spacers - easy fix

-I'm starting to not like these white axle spacers. They are way too tight ID. Some of them work, some don't. Trying to ream them doesn't work. I'm going to stop using them. Matter of fact I'm going to discard all of them.

-Weldun crown fails the drivetrain test, it's out of round and noisy. After 50 years I probably got the worst one of the bunch. I'll switch to Cox and test until I find a good one.

Good news:

-Cox Superflex wires worked fine

-Cox flag installation easy day

-Motor installed easy day

- Alchemist, Slot Car Rod, Peter Horvath and 1 other like this

Paul Wolcott

#121

Posted 23 March 2021 - 08:01 PM

What size is you Weldun? I might have one that will work for you. Some pinions also don't work well with the Weldun. Why didn't you twist the leads together? Is there a reason, or just how you decided to do it?

#122

Posted 24 March 2021 - 08:48 AM

It's a 31T. Thanks for the offer, I'll be working on this today, will let you know if I need it. You may be right, the Welduns may not "like" some steel pinions. I fear if you send me another the result would be the same.

Another factor to consider as a builder/assembler, old parts have been subject to lots of cherry-picking and we end up with the ones nobody wanted. If I don't have an absolute perfect Cox crown to replace it I'll probably dye a Parma and fogettaboutit.

Good question about twisting doubled wires, or not. The purpose of doubling wires, for the pros, was in case one broke you still had power. The truth on this car is, on the tiny Mabuchi connection tabs, they are twisted individually but not together. Where they enter the flag holes, they are twisted together, just for simplicity sake.

Paul Wolcott

#123

Posted 24 March 2021 - 09:50 AM

No 31's. I know Rick uses Sonic pinions on his Weldun equipped cars and that they work well.

The leads make sense, with them twisted at the guide.

- Pablo likes this

#124

Posted 24 March 2021 - 10:23 AM

That's what I usually use on my vintage builds, is Sonic. Reasonably priced, readily available, perfect quality. Swiss taught me to always use steel pinions unless it's an exact replica that must be brass. Brass wears quickly on high powered motors, subsequently chewing the crown or spur, further wearing the pinion, until mutually assured failure ![]()

I found a Cox 31T that appears fairly new and true, easy fix. The answer to my spacer woes is a "Spacer Party". All 1/8 spacers dumped on the desk, with a new axle that mikes at .1235". The steel ones go back in automatically. I discovered quickly there are "plastic" spacers here that are way too tight. I found three so far and they will be re-purposed. The good ones go back in the container.

Hope you enjoyed this slight "burp" in my build process. Here at The Wolcott Ranch, if we discover a hiccup in the assembly line, building stops and the problem gets corrected. Plus, it gives me time to eat a sandwich ![]()

- Peter Horvath likes this

Paul Wolcott

#125

Posted 24 March 2021 - 11:36 AM

Left side, good. Right side, discards. Some as so bad they actually need to be forced to go on the axle. Almost all of the 1/16 wides are wobbly enough to be verified with the naked eye

Ain't complainin'. Just sayin'. Slot Car 101, ensure your mass-produced parts are as perfect as you want them to be ![]()

- Peter Horvath likes this

Paul Wolcott