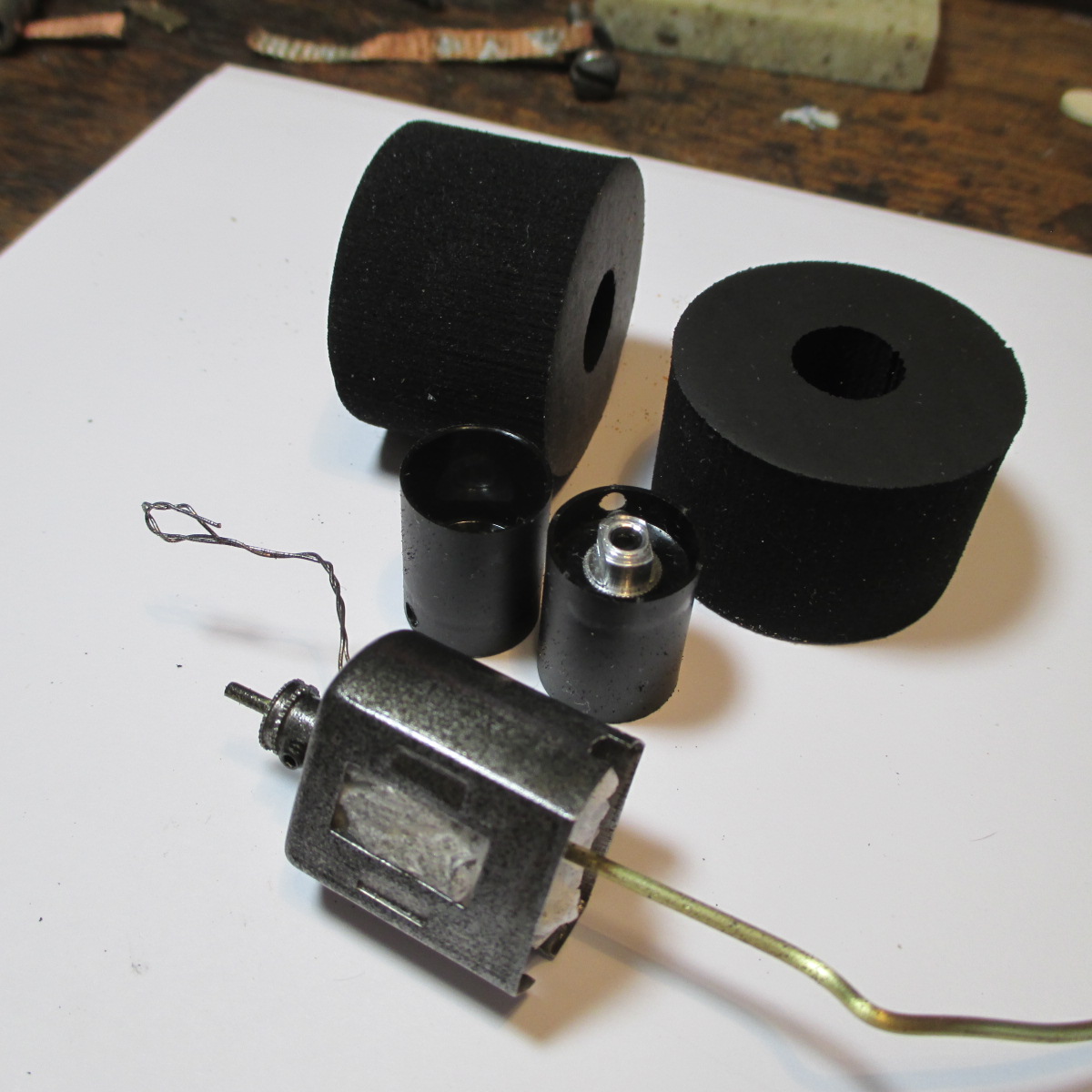

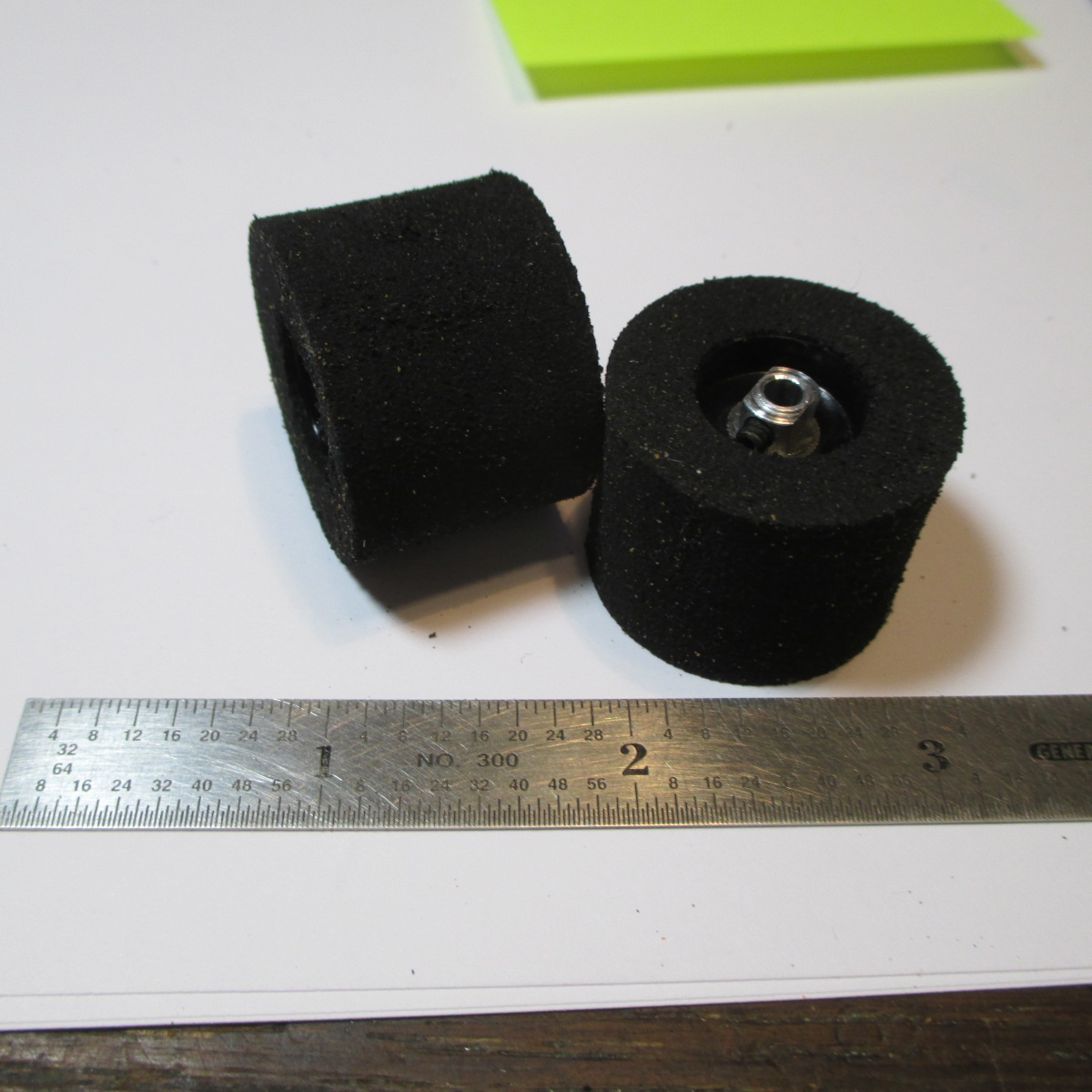

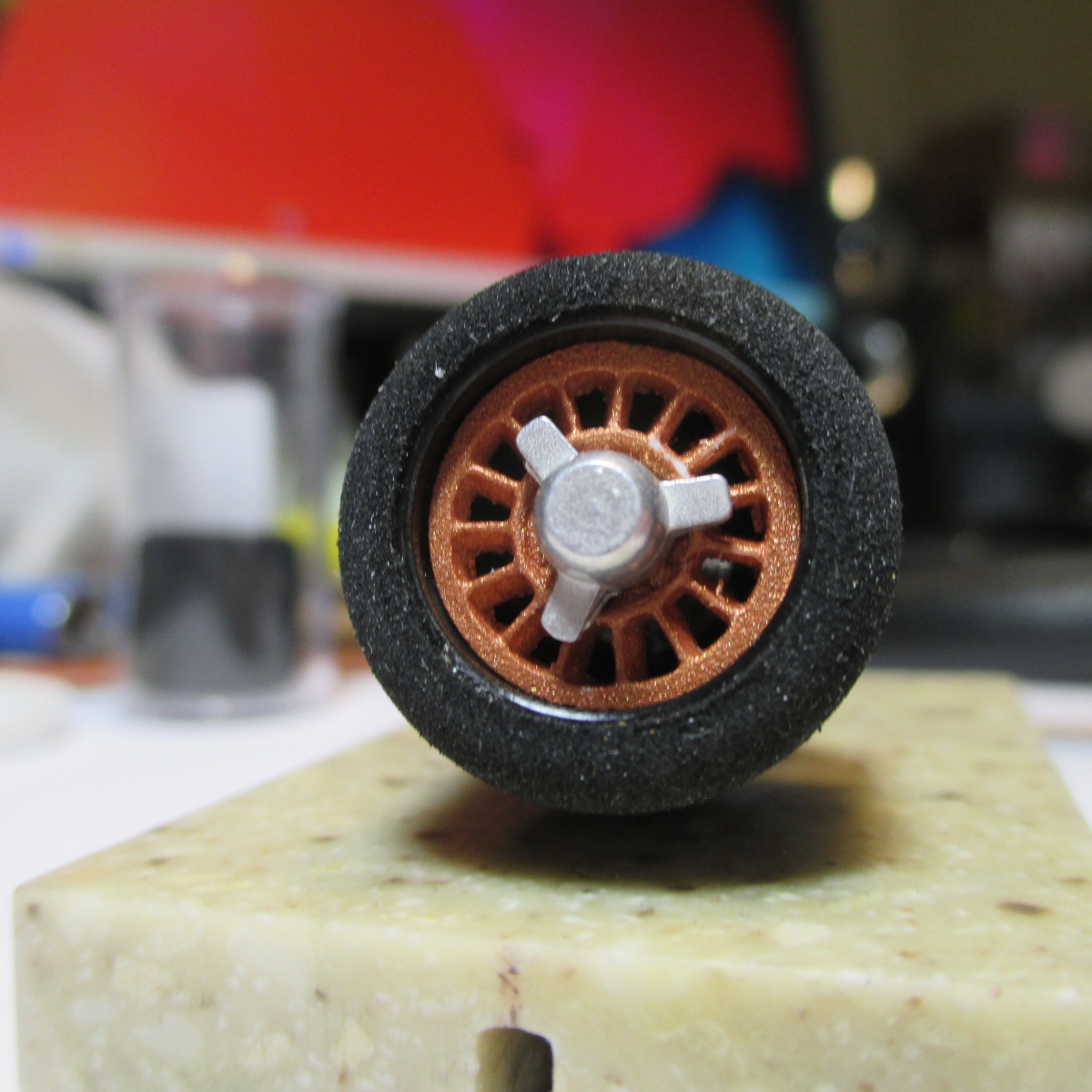

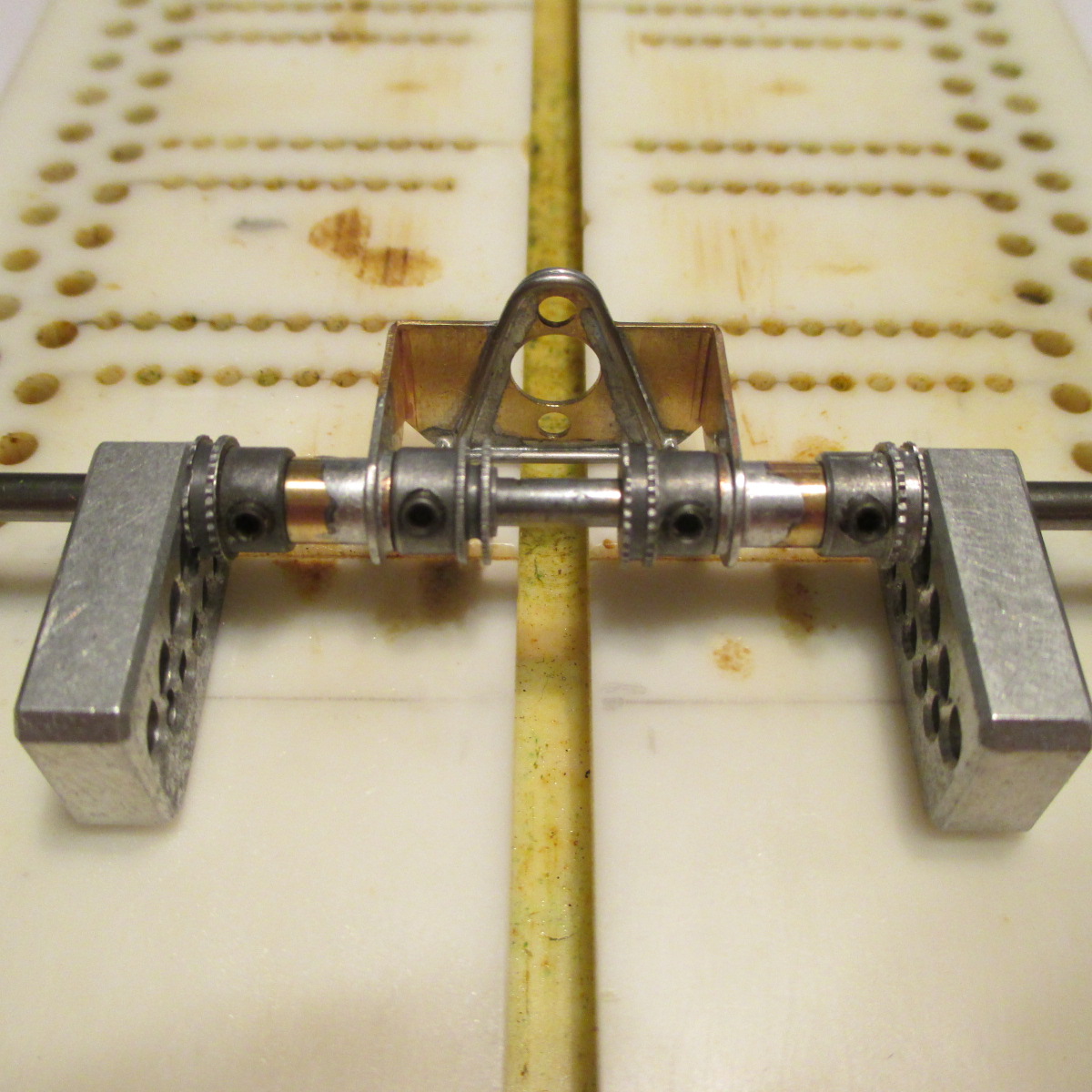

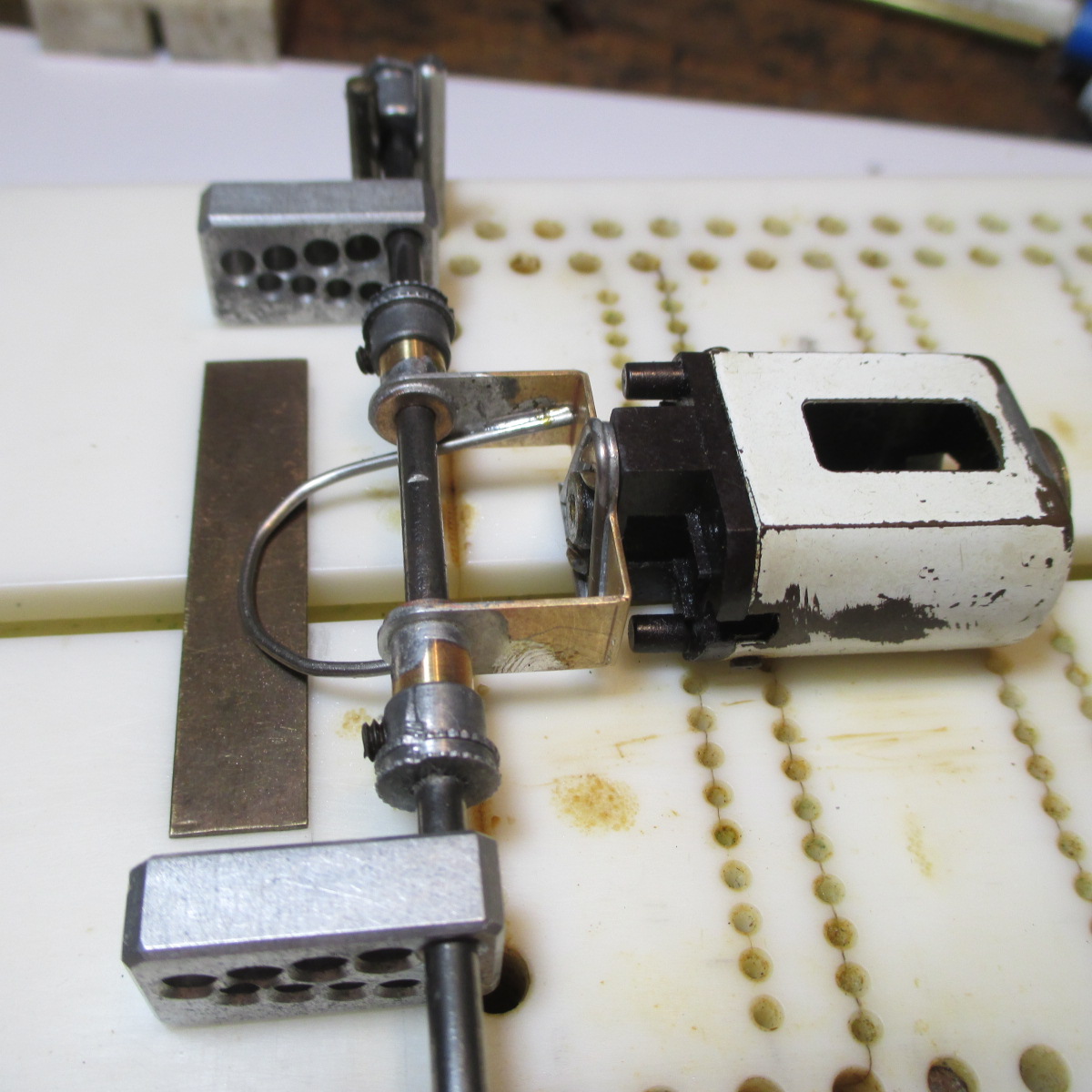

Assembly for testing and quality control. Snug down the screws little by little to ensure the arm remains free. Perfect

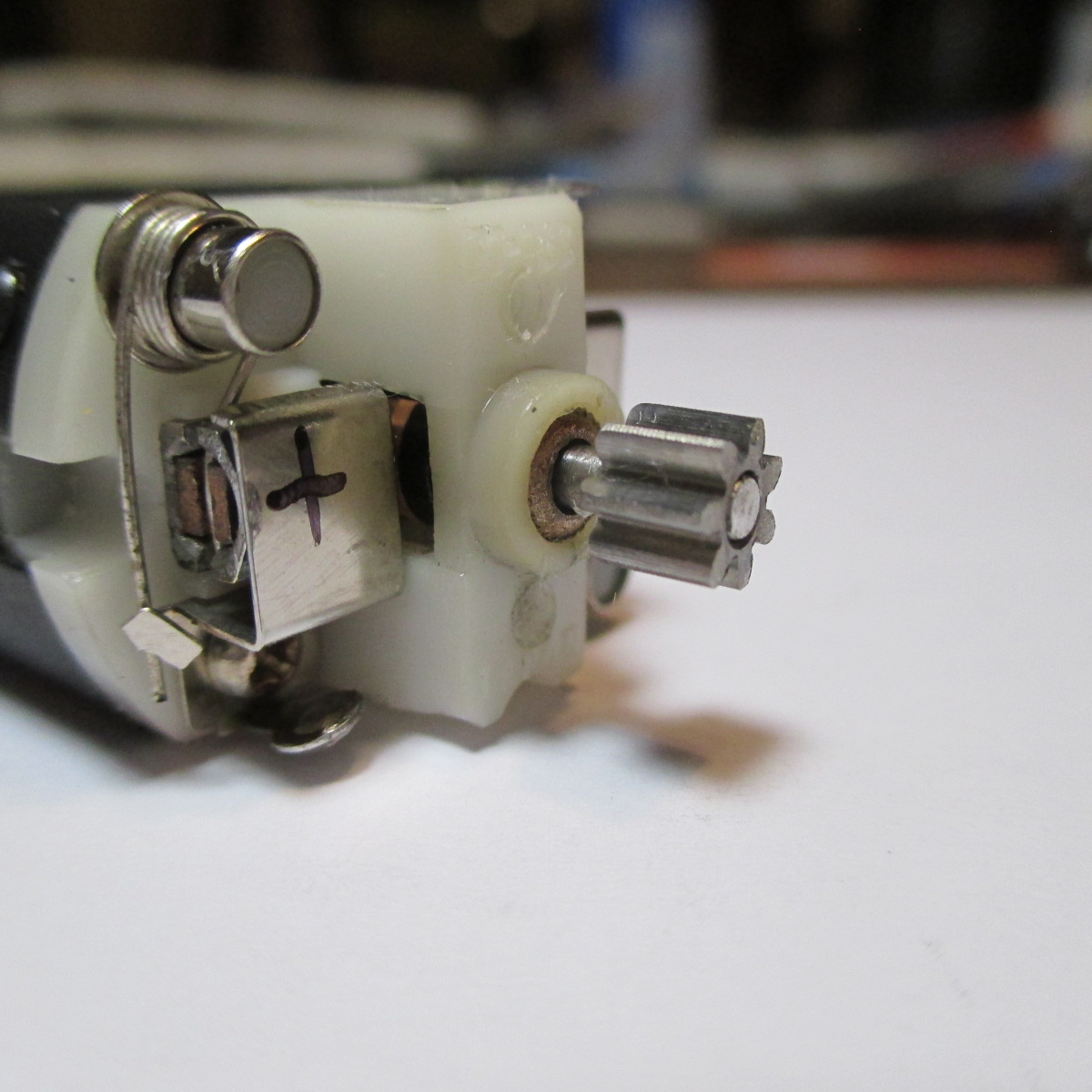

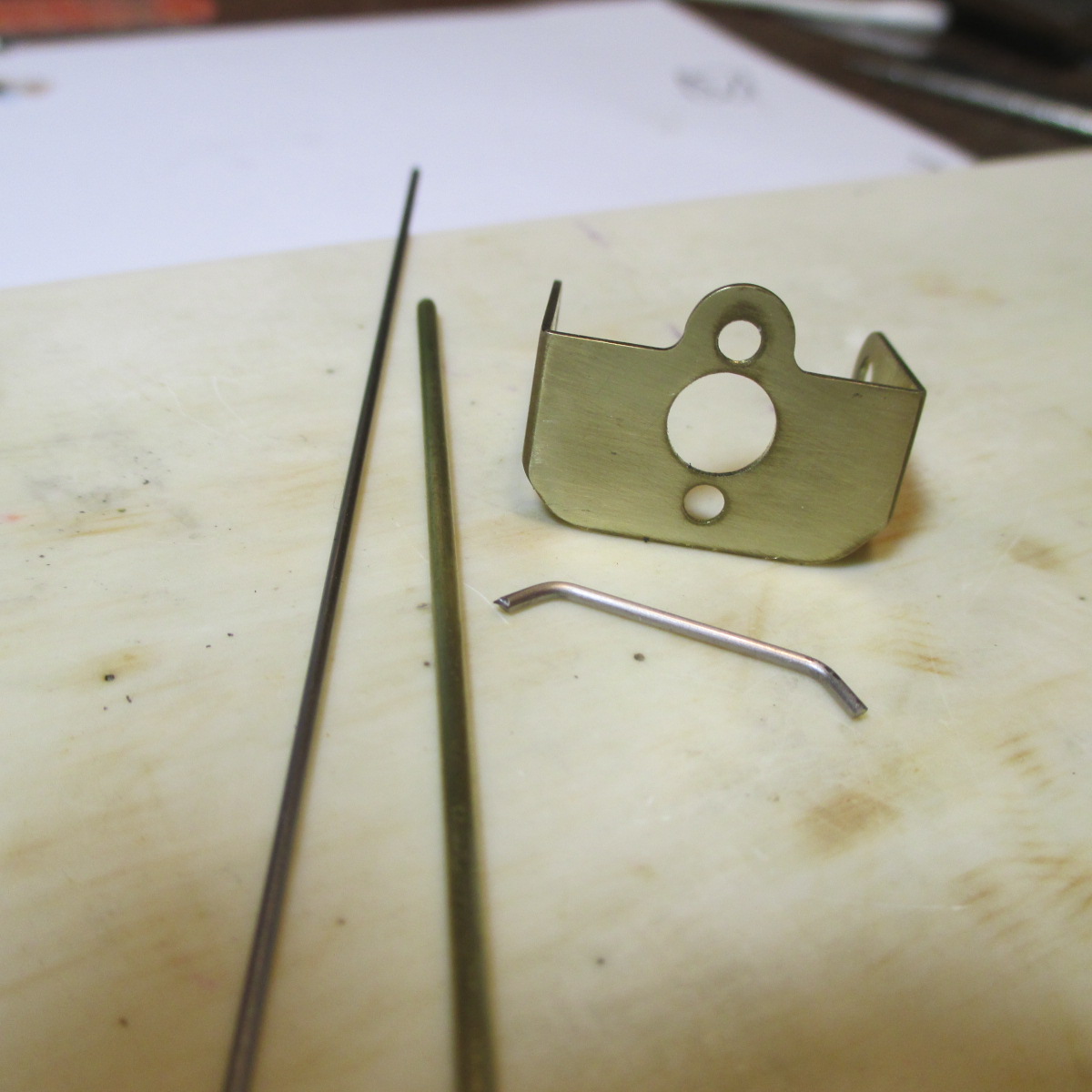

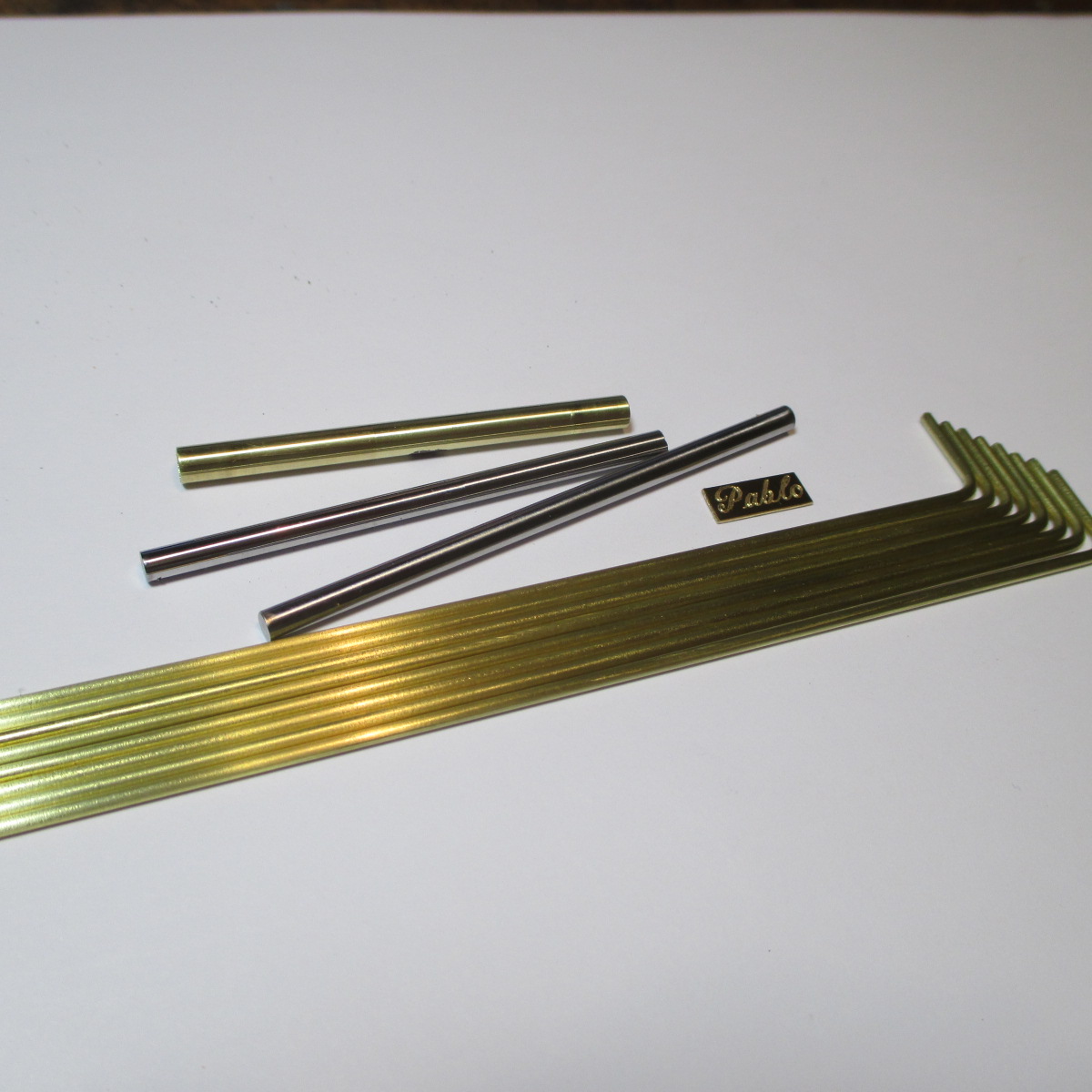

Make sure the brushes insert with the markings "up". Install springs, oil BB and bushing, ready to test.

Apply positive wire to positive brush side. Start at minimum volts and check arm rotation direction. If it's correct, you are good and ready to break in. If rotation is wrong, swap brushes and wires, then continue. The arm is timed CCW, so it needs to rotate CCW

Mine were correct. Arm started spinning smoothly and immediately. This is the first good sign of a happy motor. I applied 3 V and watched the amps, started at .9 and steadily decreased to .75 within less than 1 minute. Sounds super smooth and temp is dead cold. After a couple more minutes she stabilized at .8 amps. This is classic behavior for a healthy motor.

Disconnect, a re-oil, then fed some power up to 5V. Amps about .8 again. Super smooth, absolutely cool, and sounds potent. So the test is a success. I removed the hardware, making sure to match everything.

Motor lessons over ![]() Any questions?

Any questions?

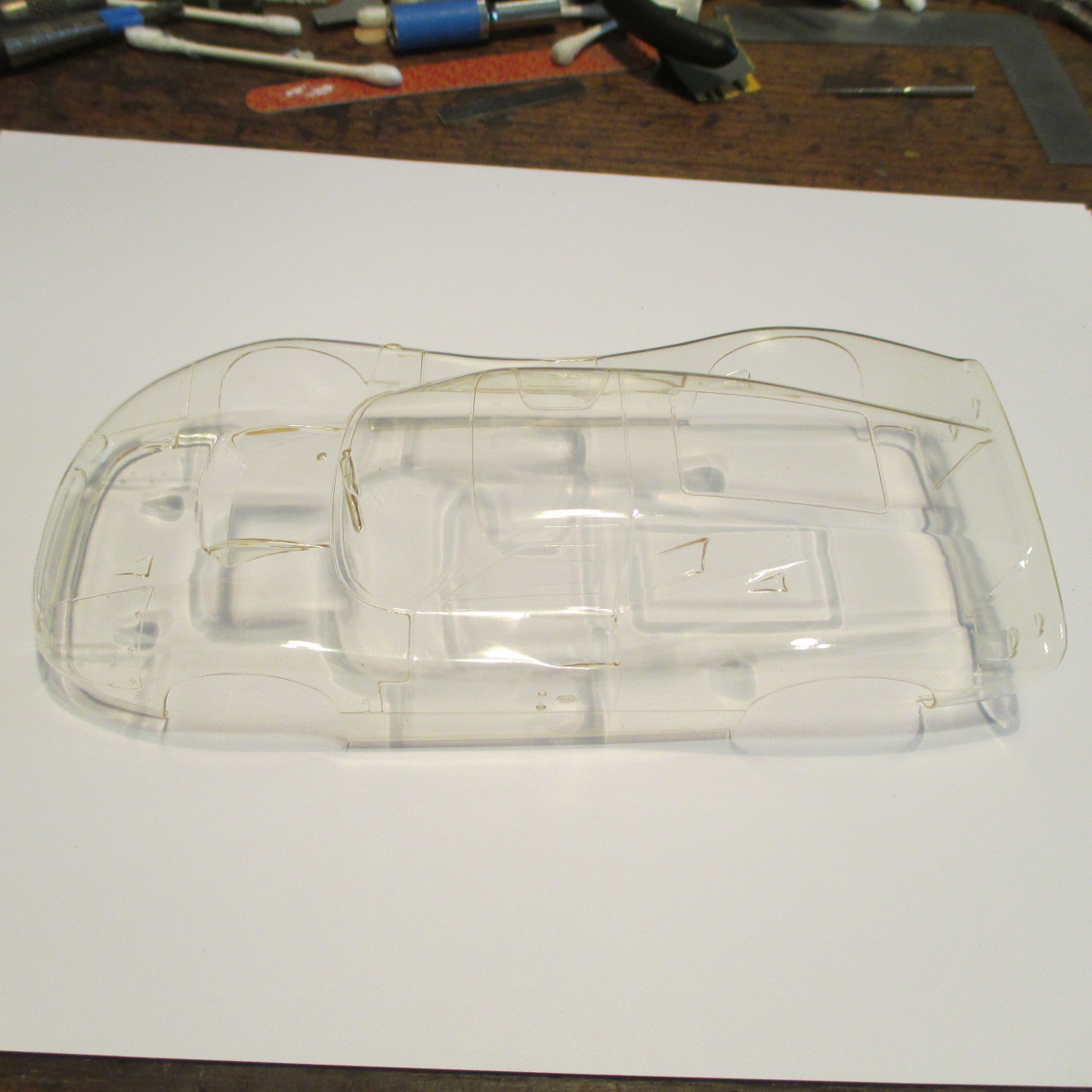

Once the weather gets warm and dry, the can will be masked and ready for paint