Jim, I'm glad that you are happy with the parts I send to you.

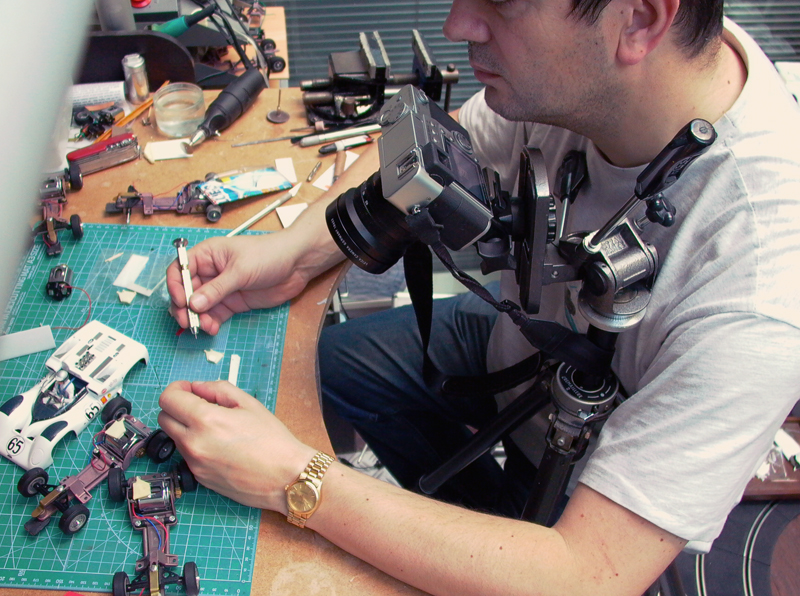

I still have things to make to other slotblogers. I know that… Please be patient. This will come soon and for sure before the end of the year. Jim Williams can testify that he had to wait (and wait, and wait …), but apparently he is satisfied. I do all this during my hobby time and have not enough of it … (like most of us I guess...)

OK guys (and Ladies…) it's been quite a year since I show you something new about the restoration of Cox Chaparral cars.

I hope that everyone had fun during the summer holidays. Now it is time to revert to those Chaparral cars.

Last time I thought that we were about to see how to paint those cars, what strategy had to be used when there were complex things to do like painting the 2E with those dark blue areas on white, or some Brown on white as for the 2A.

But recently I worked on the four 2D that I have (3 of them were mine, the fourth one belonged to a friend who unfortunately had to sell things; I bought the fourth one together with his 2A and his 2E). Between you and me, I may sell a 2D, one or two 2A, a copy of the 2E but will keep my two genuine 2Es.

So we will see the masking and painting tricks later on.

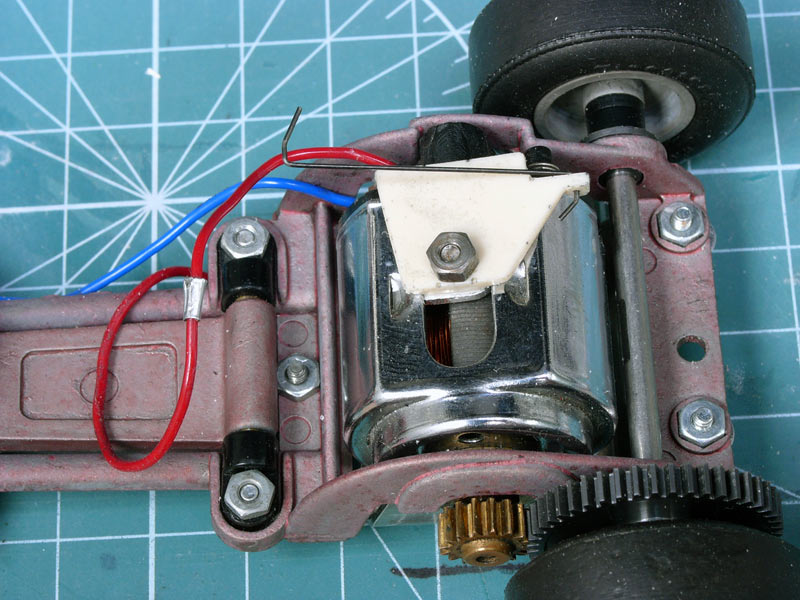

About the2D, then:

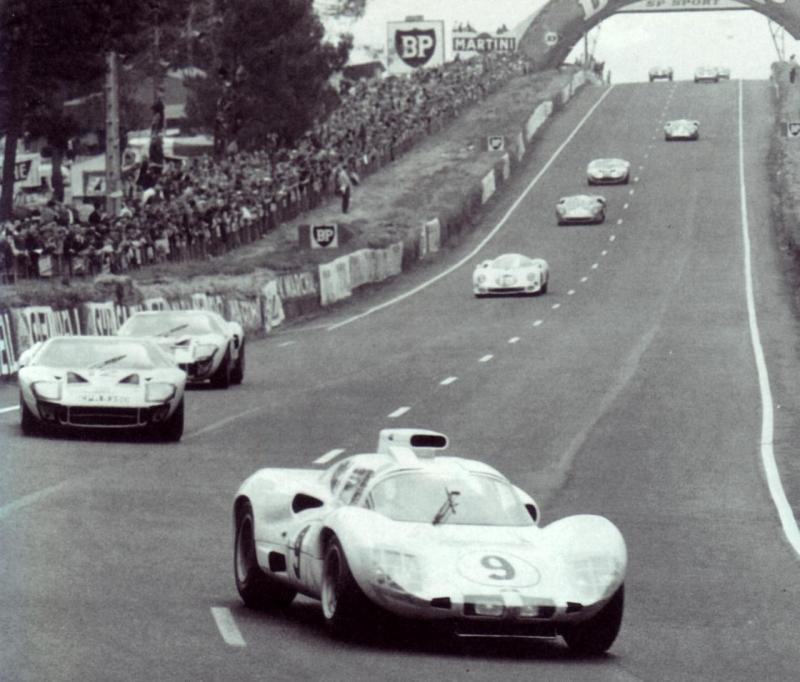

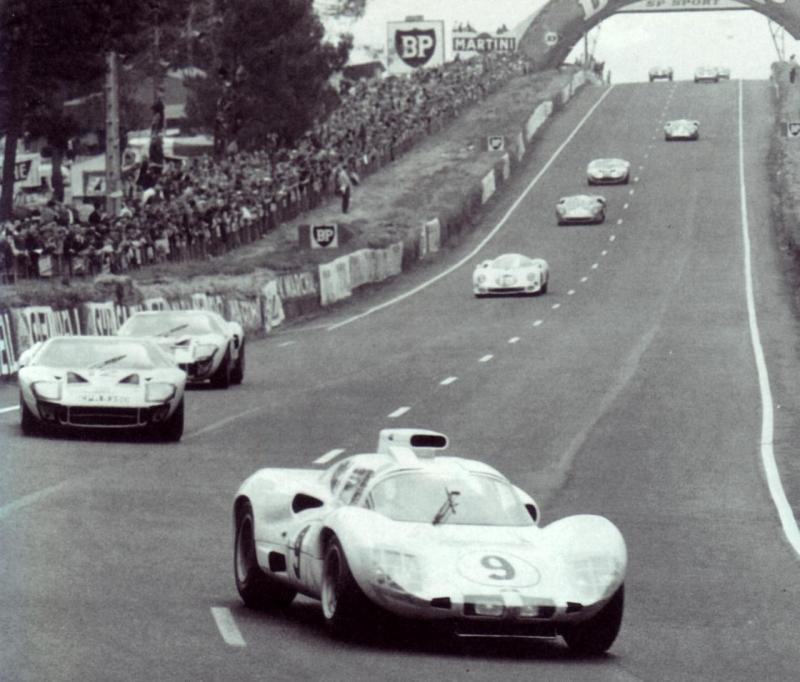

I quickly came to the conclusion that the Cox model was perfect to either represent theNurburgring car, with number 7, or the car that raced in the 1966 edition of Le Mans 24h race (with number 9).

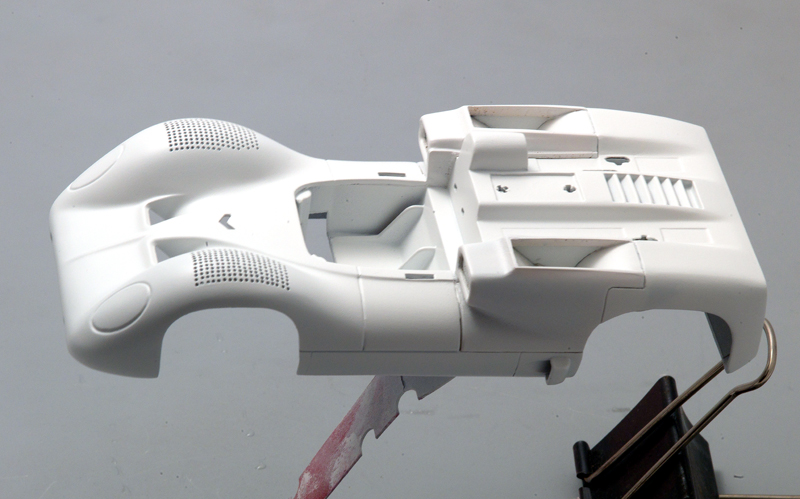

But to either make #9 or #7 we first have to work on the body…

- On both cars, the rear aerodynamic blade is too small, too flat as there is no embossment (on the real cars this blade was bolt on the body).

We will see that each of the two cars (between # 7 and # 9) has its specific blade.

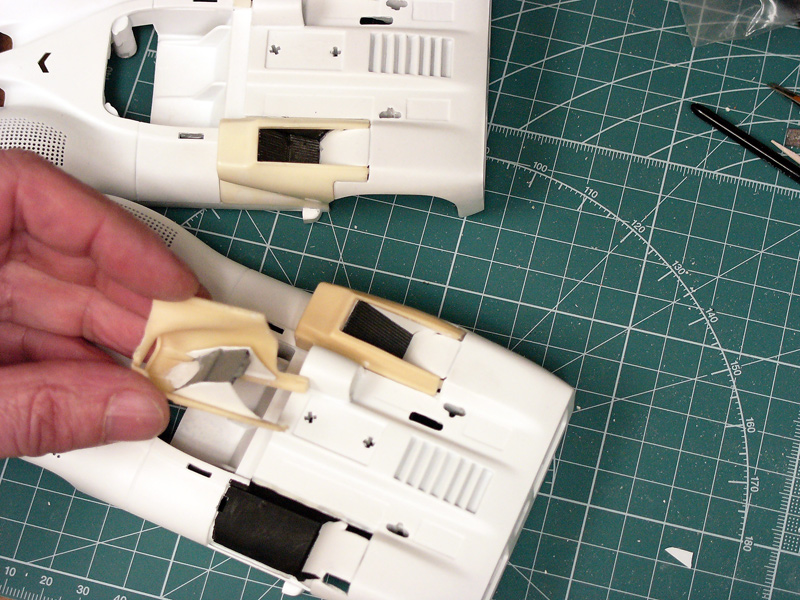

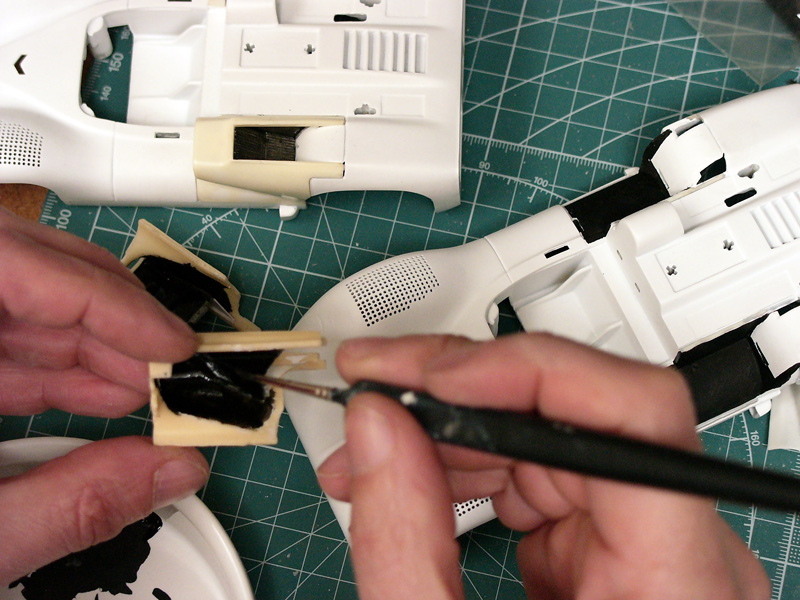

So we have to remove the emergence of a poor blade on the Cox bodies and create new parts.

- On LeMans car (#9), the nose has to be modified in order to have front additional lights visible behind the transparent light covers.

- On the Nurburgring car (#7), the top should be flat, with no fairing for the rear view mirror.

Let's first consider the Le Mans' race car:

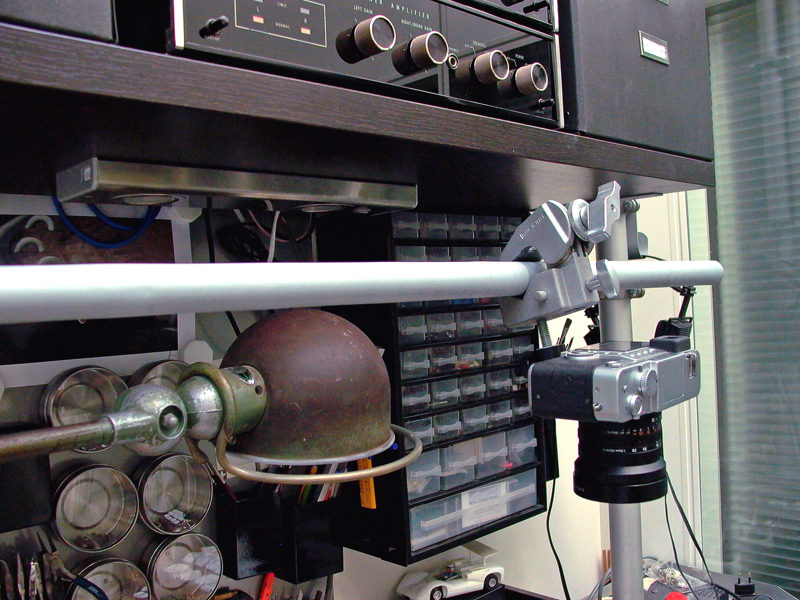

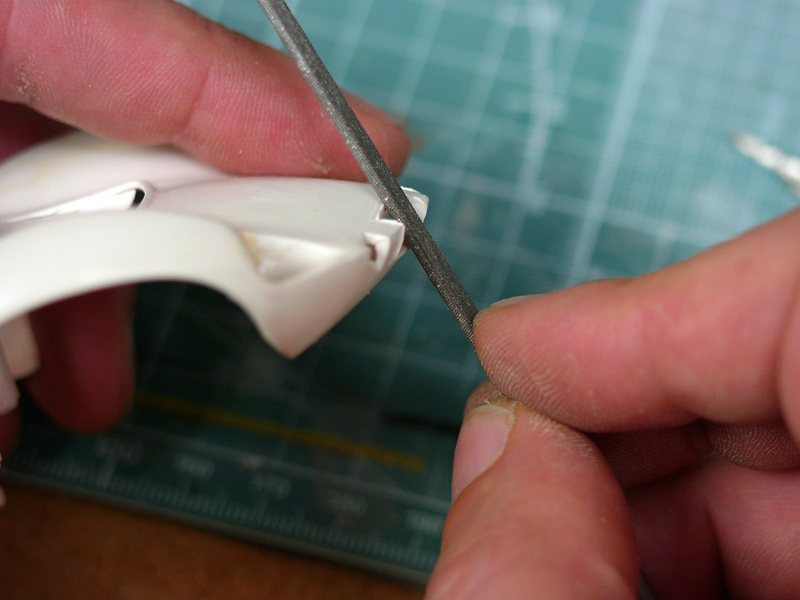

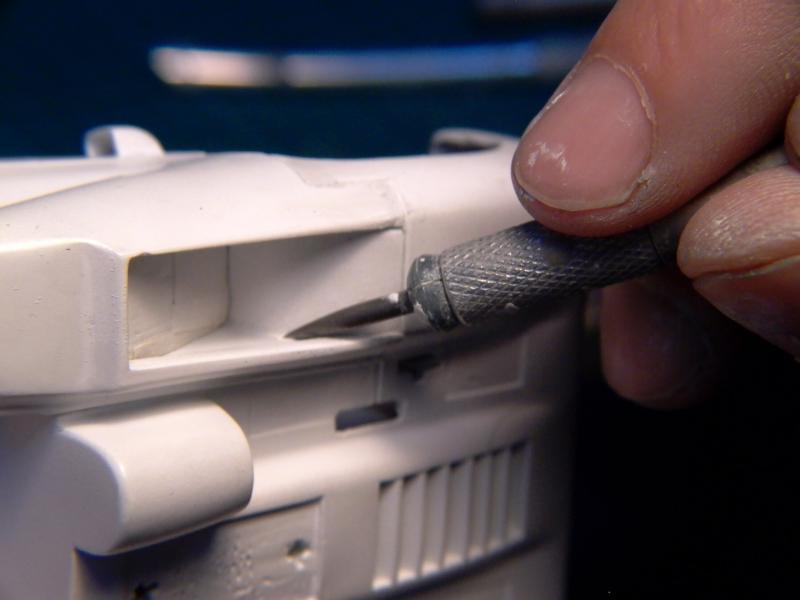

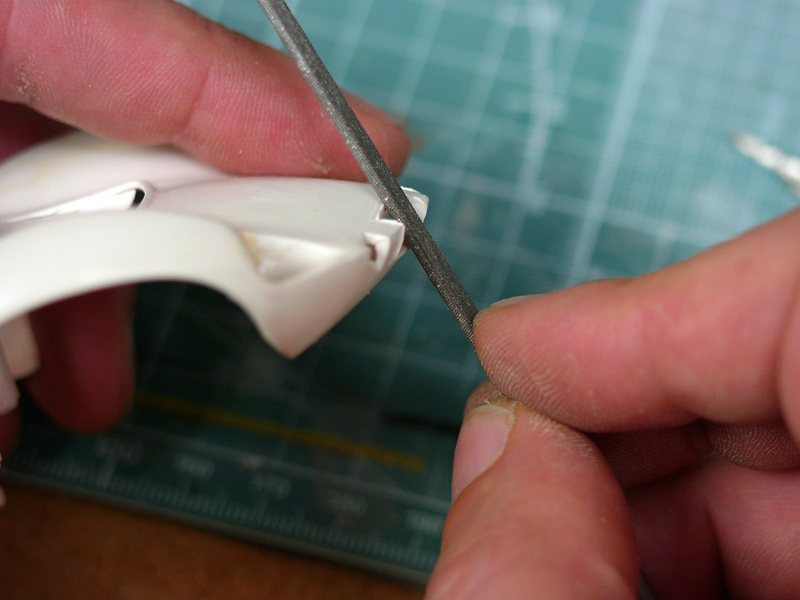

To open two apertures for the additional lights, I first used a pyrographer. It looks like an electric iron and can be equipped with different tools, notably a blade.

I cut inside the embossed lines that simulate the junction of panels on the model, and not exactly

on the lines.

It is safer that way. Then you can finish with a file. The transparent covers shall be made the same way I did for the 2As.

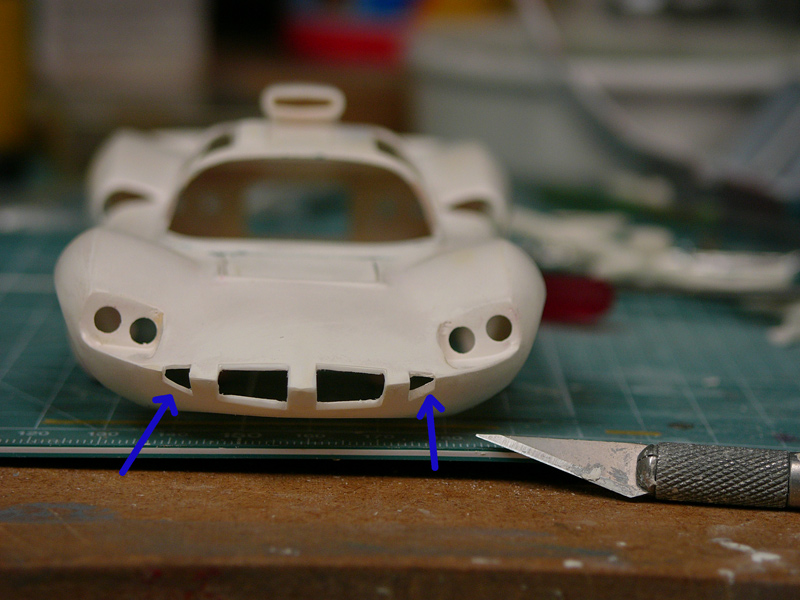

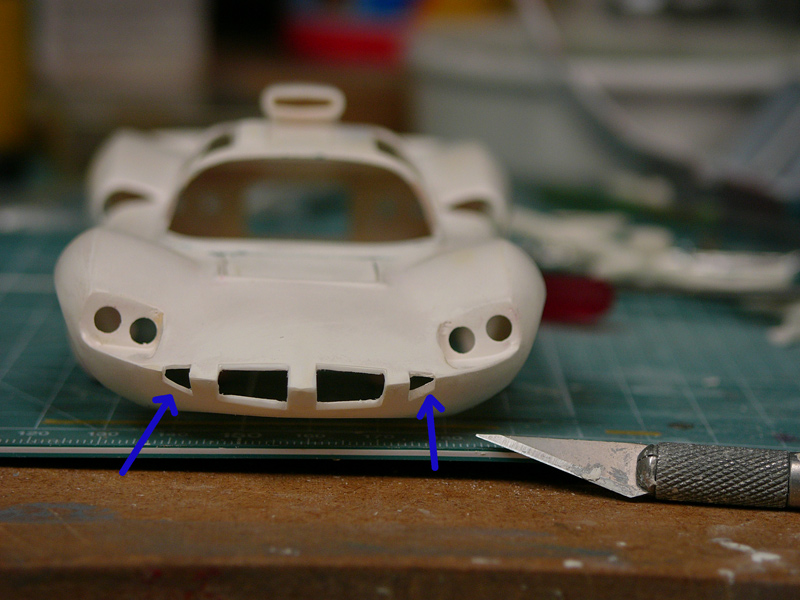

Once this done, you have to widen the little triangular apertures with an X-acto or similar and this, to simulate a more realistic thickness of the body. Those apertures are made for cooling down the front brakes.

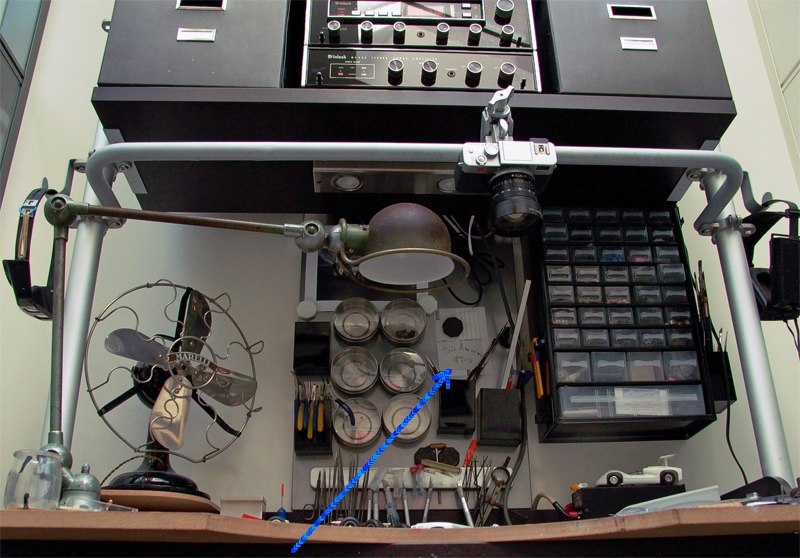

Here below, the work is still to be made on the right of the picture (on the left side of thecar).

Of course, widening those triangular apertures has to be done on every 2D, no consideration of the race.

On the two different versions, you will also have to file down the rear left light (on the sole left rear wing, at the rear of the wheel). There is no race number on the rear left, so no light either. On the right side, on both models, there is a race number on the rear (and on the door of course).

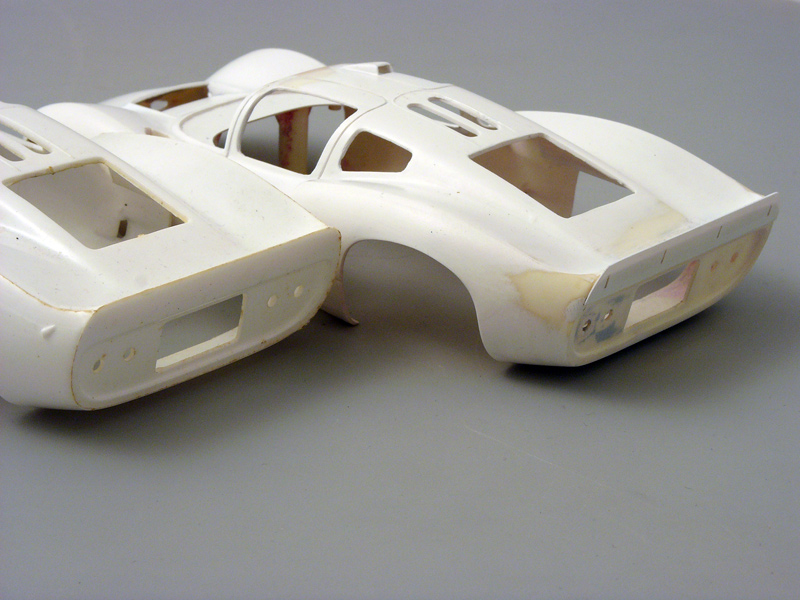

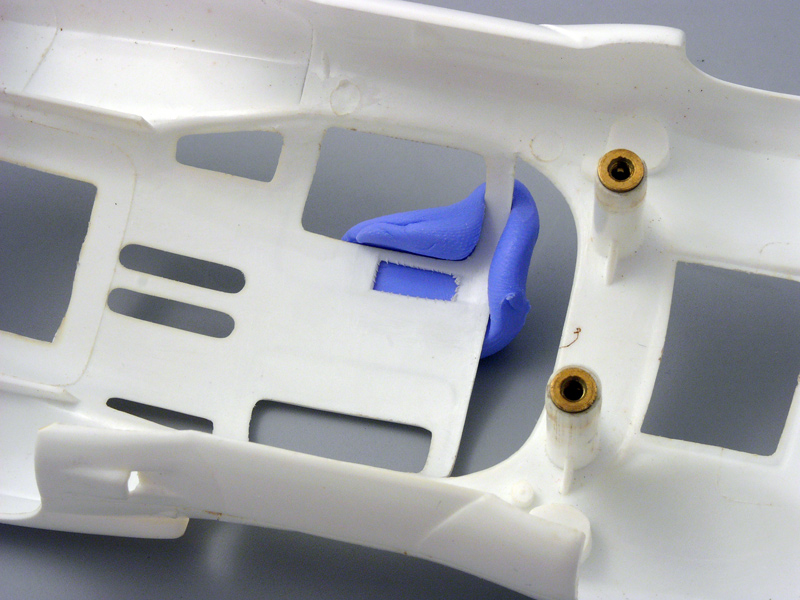

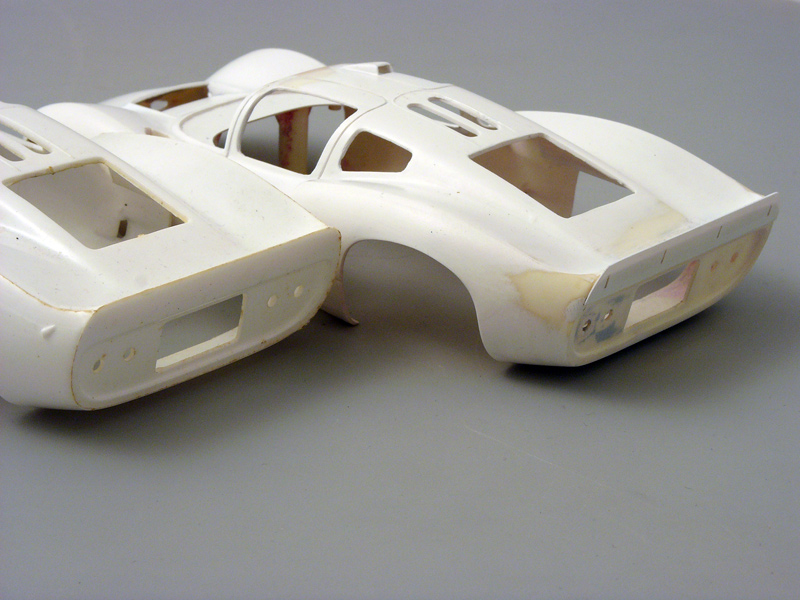

Same for removing the embossment at the rear that is supposed to be an aerodynamic blade, this has to be made on both versions.

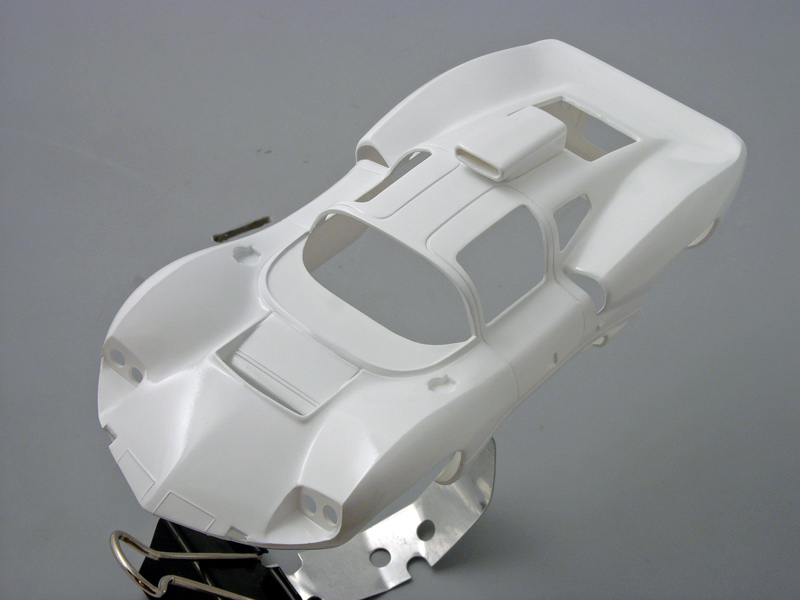

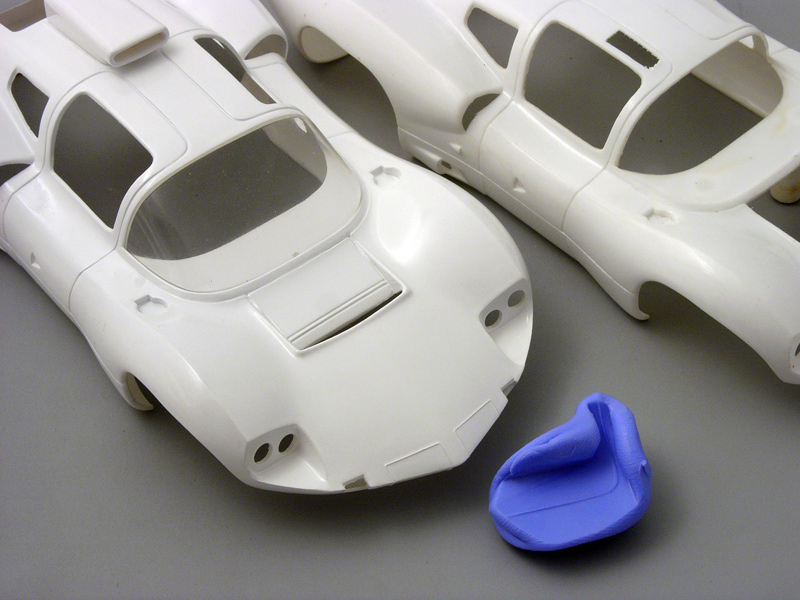

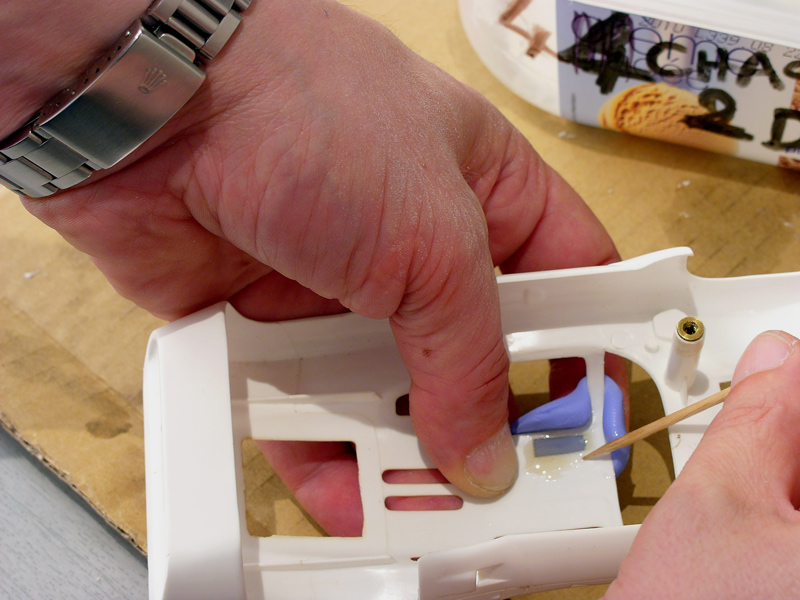

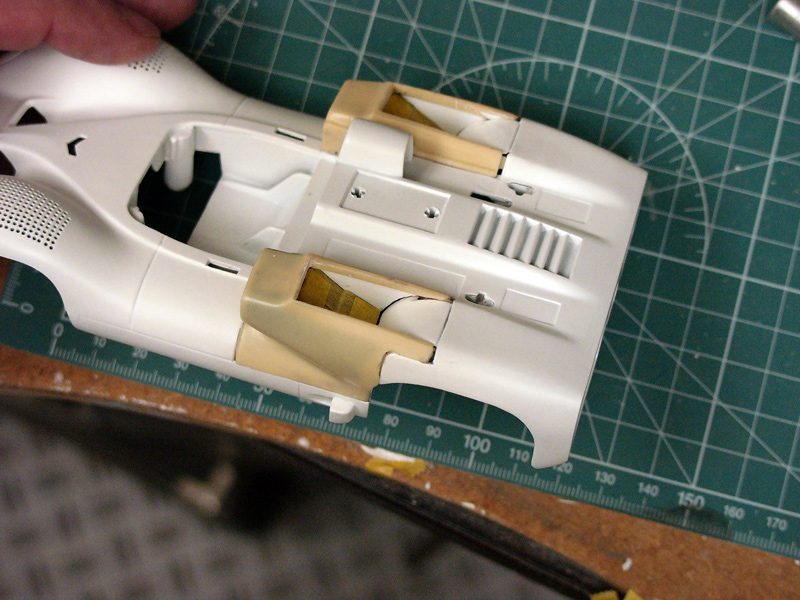

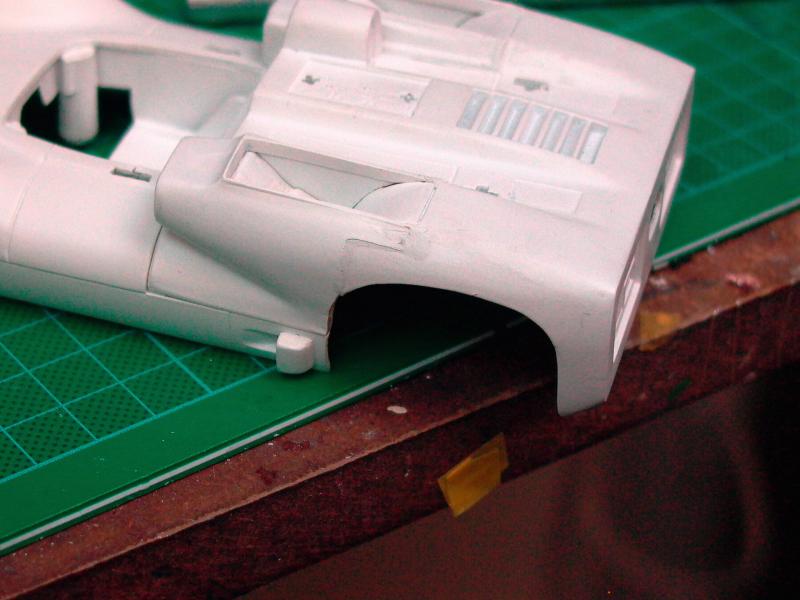

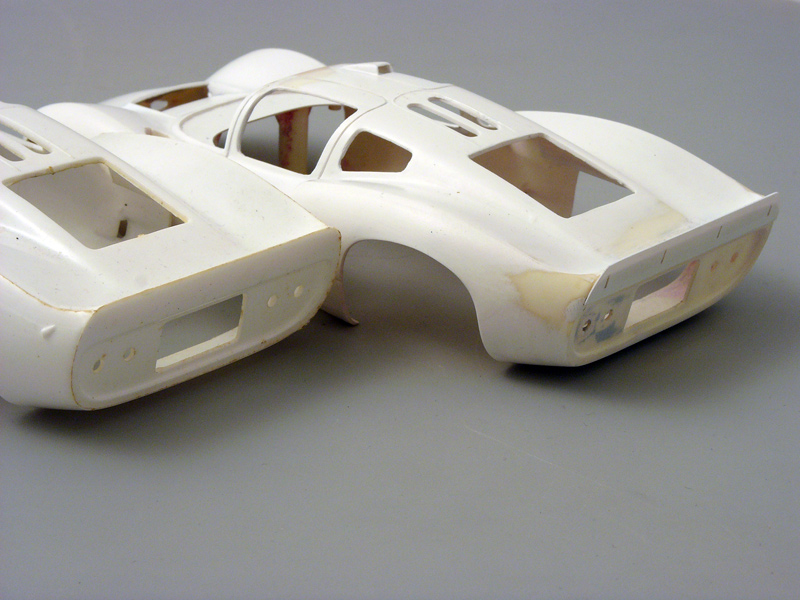

Here you see from left to right: the modified body with a new rear spoiler, a body without the genuine embossment made by Cox (removed with files and sand paper), the genuine body.

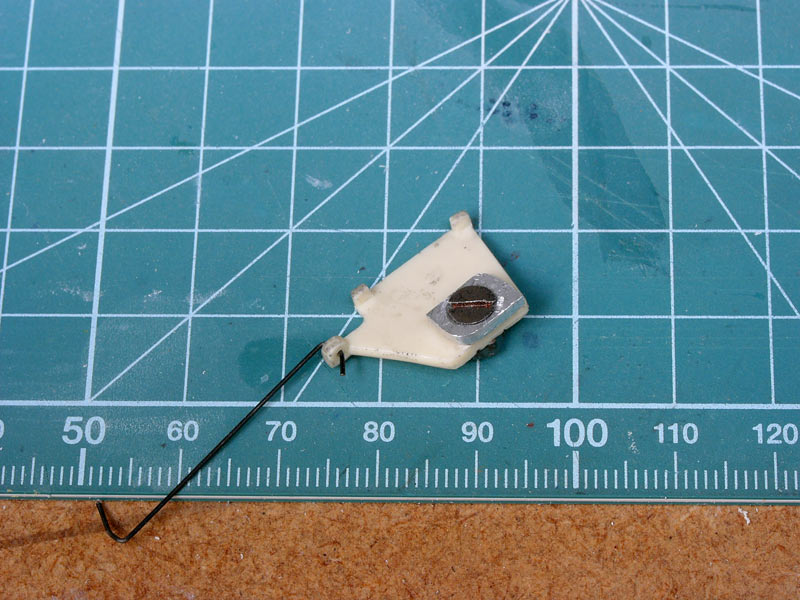

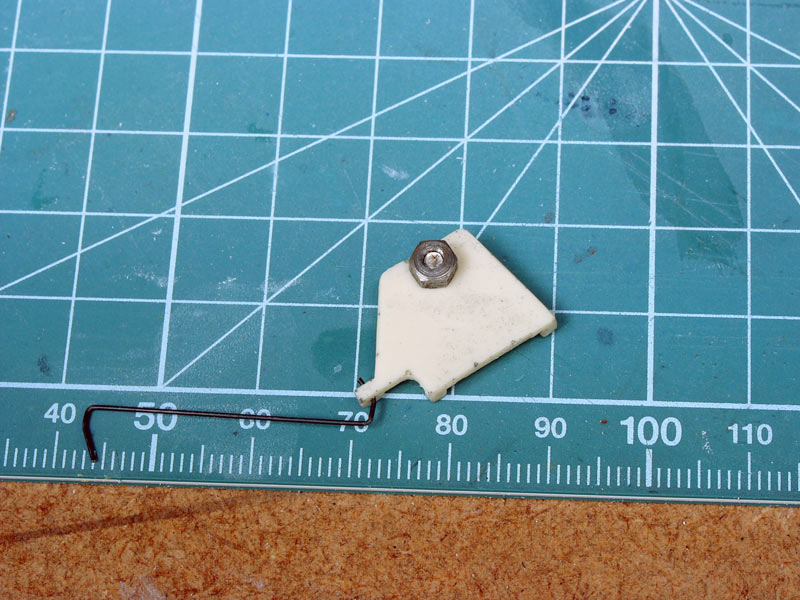

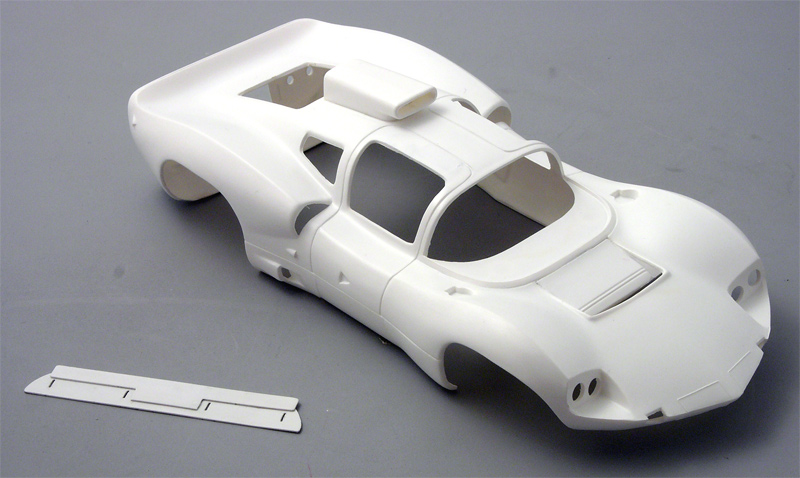

Now, to revert to the specific Le Mans version, here is again the difference between the genuine Cox body and the modification for the "Le Mans" rear blade.

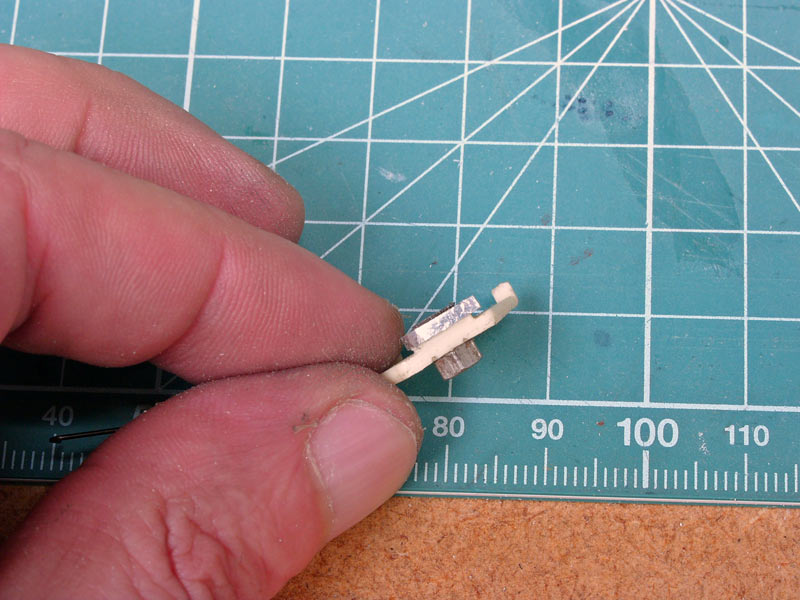

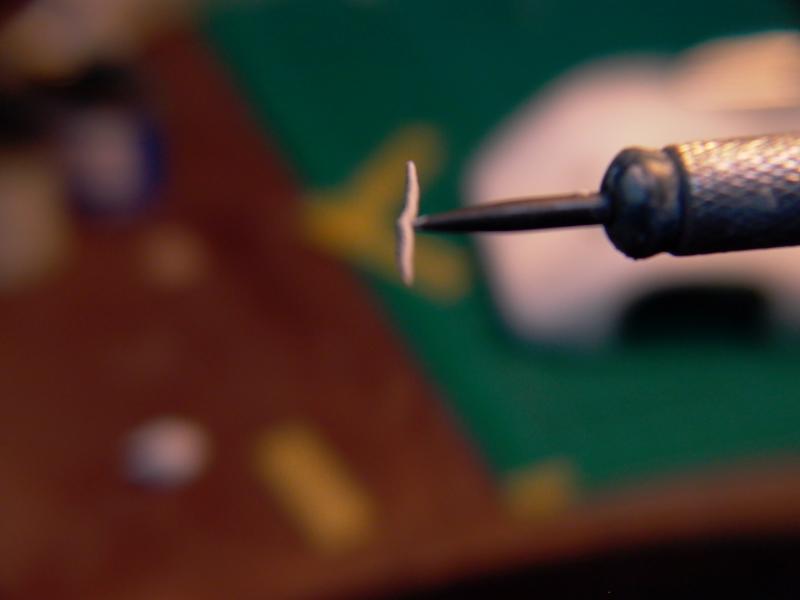

The additional part was cut off in a thin plasticard foil.

The rear spoiler of the Nurburgring car is higher and made of 2 parts:

(To be continued)

(To be continued)