That's why I'd buy a couple of examples of any Dynamic repop that Victor of TrueScale would come out with. He never did a Mirage roadster though.

Howie's amazing 1967 Arco coupe/sports car

#76

Posted 27 July 2015 - 08:09 PM

That's why I'd buy a couple of examples of any Dynamic repop that Victor of TrueScale would come out with. He never did a Mirage roadster though.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#77

Posted 27 July 2015 - 09:58 PM

Dennis David

#78

Posted 28 July 2015 - 12:36 AM

How do you plan to keep those washers from coming unsoldered every time you add a rail upright?

Paul Wolcott

#79

Posted 28 July 2015 - 09:36 AM

I started with nothing in the early '90s. I went to toy shows, swap meets, and then searched eBay. While most "collectors" were buying Little Red Wagons, La Cucarachas and the like, I bought "parts" because I like to scratchbuild.

Hi Pablo.

I'll be soldering the rails on either the front or back of the axle tube so the whole tube won't get heat from the iron. I'll also use the Mike Steube DVD trick of watching the existing solder on the washer. If it starts to change from dull to shiny silver I'll know to back off. If worse comes to worse and I get it too hot it will have nowhere to go as it's held in place by the jig wheel setup.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#80

Posted 28 July 2015 - 02:30 PM

I might be doing one of those assemblies real soon, and I may try soldering the washer after the rails are on. Would that work?

Paul Wolcott

#81

Posted 28 July 2015 - 05:34 PM

Time will tell. You know what they say about the "best laid plans..."

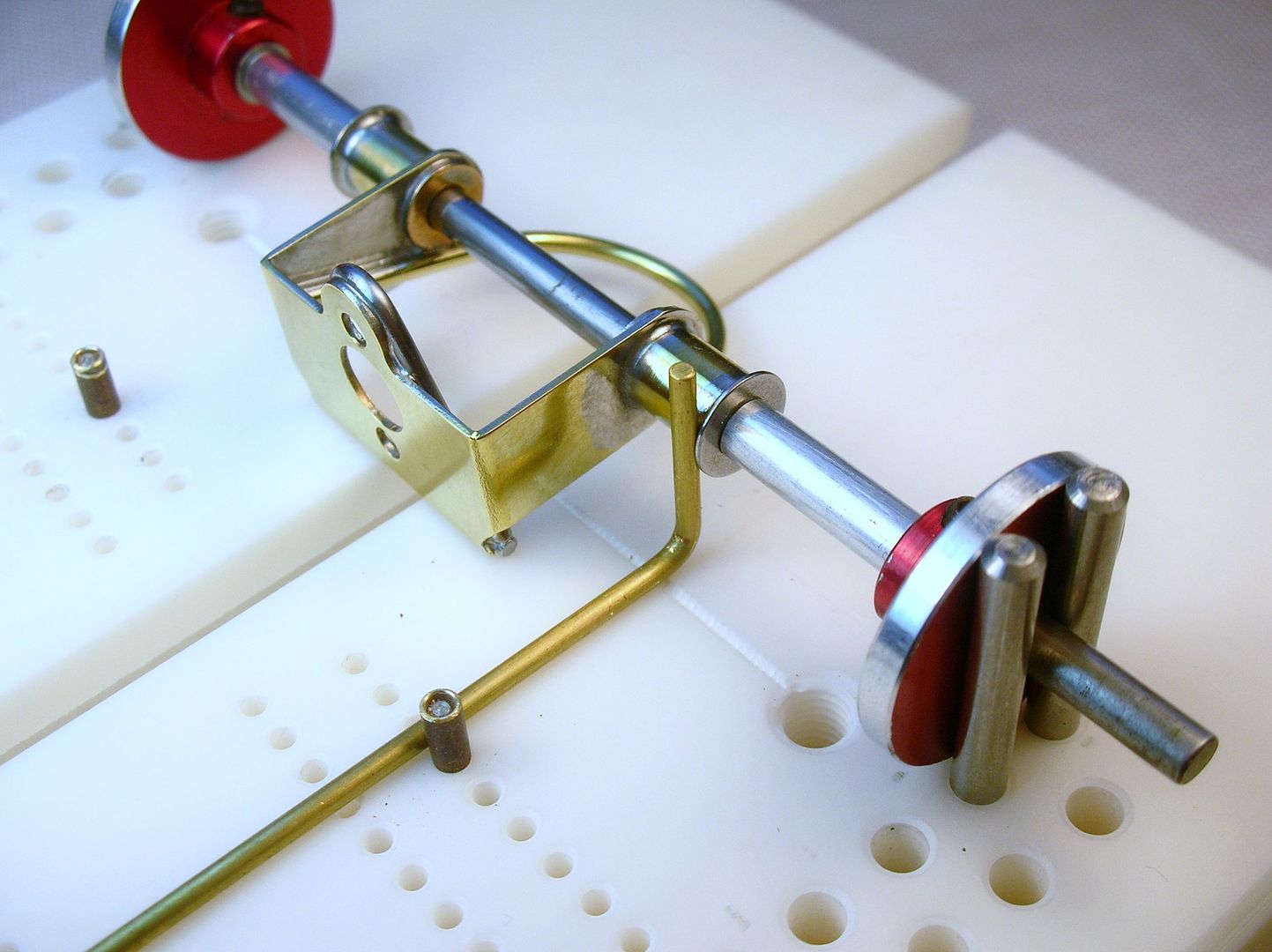

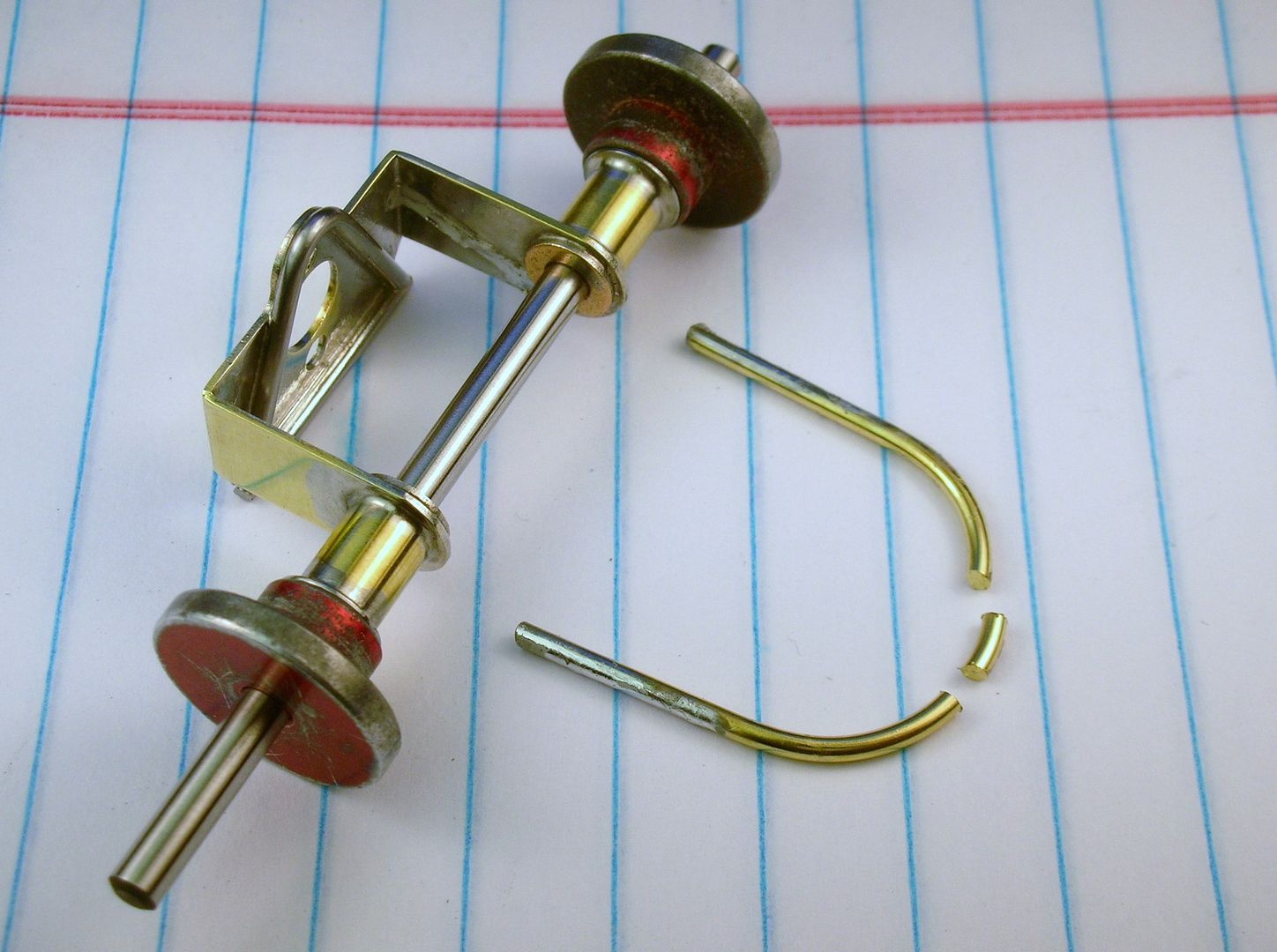

Note that two out of three of these original chassis did not have the thrust washers soldered on. It was Howie's preference to have his soldered. I wasn't going to but now that I see them soldered I like it, too:

Either way works and is period "korrect".

- miko and James Fetherolf like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#82

Posted 28 July 2015 - 07:59 PM

I got a PM from Howie last night. He really likes the progress but...

... don't hate me too much but I had a major revelation when I looked at the post... that the brace was steel.

![]()

![]()

![]()

OK, I've got an idea... but don't tell Howie! A bit of silver paint on the brass brace and it should look just like steel!

![]() Just kidding, Howie! What Captain Rick solders, Captain Rick can unsolder:

Just kidding, Howie! What Captain Rick solders, Captain Rick can unsolder:

Here's the steel brace in place of the original brass piece:

There is some light being shed on the motor Howie used. I might pause on the chassis and do some motor stuff as we still need to settle on wheelbase and guide lead to move forward with the chassis...

- endbelldrive, miko and James Fetherolf like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#83

Posted 28 July 2015 - 08:23 PM

Thanks, Rick. ![]()

Paul Wolcott

#84

Posted 28 July 2015 - 10:02 PM

Nice early progress! ![]()

Soldering brass and getting stuck into motor parts, always fun watching your builds. ![]()

Any further forward on the body front yet, Rick?

#85

Posted 29 July 2015 - 06:03 PM

Nothing on the body yet, Paul, so I'm going to start rounding up parts for the motor.

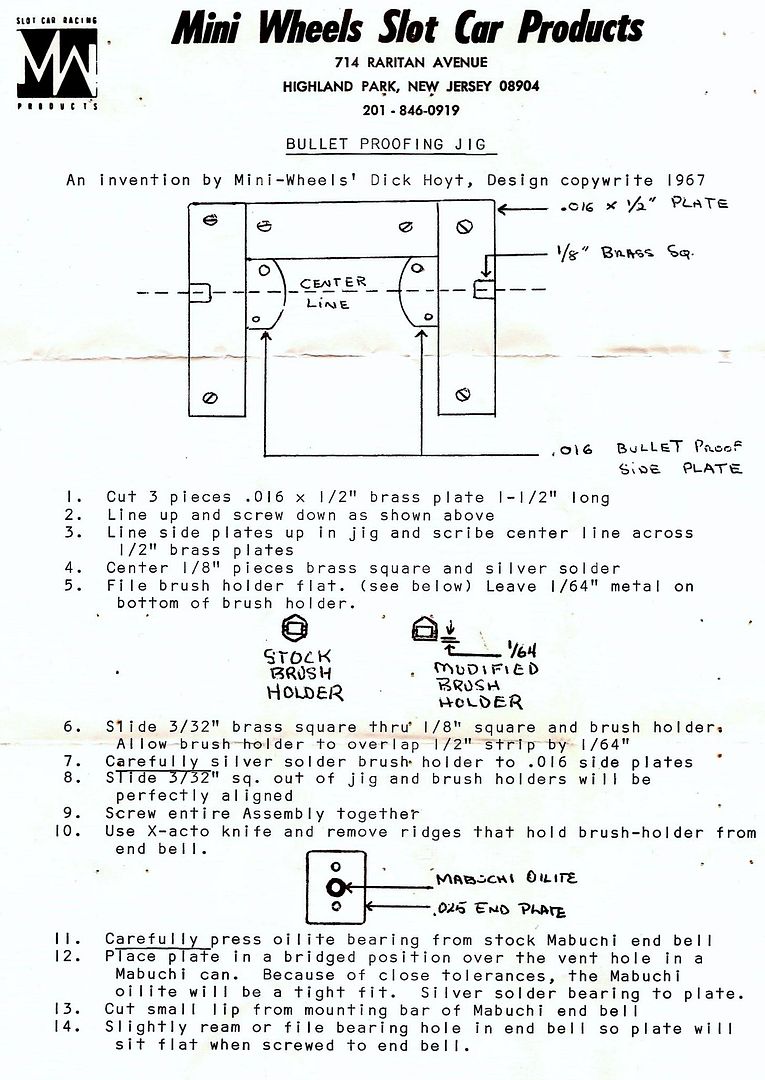

But first here is a motor build article from the same period, "Bryan Warmack Does A Motor". Of course Howie didn't necessarily do his motors exactly the same way but it's an interesting look at the process in very late 1967 to early 1968.

You can click on the picture to enarge it to read the article:

Howie, here's what I have available and you have the final say as to what's used.

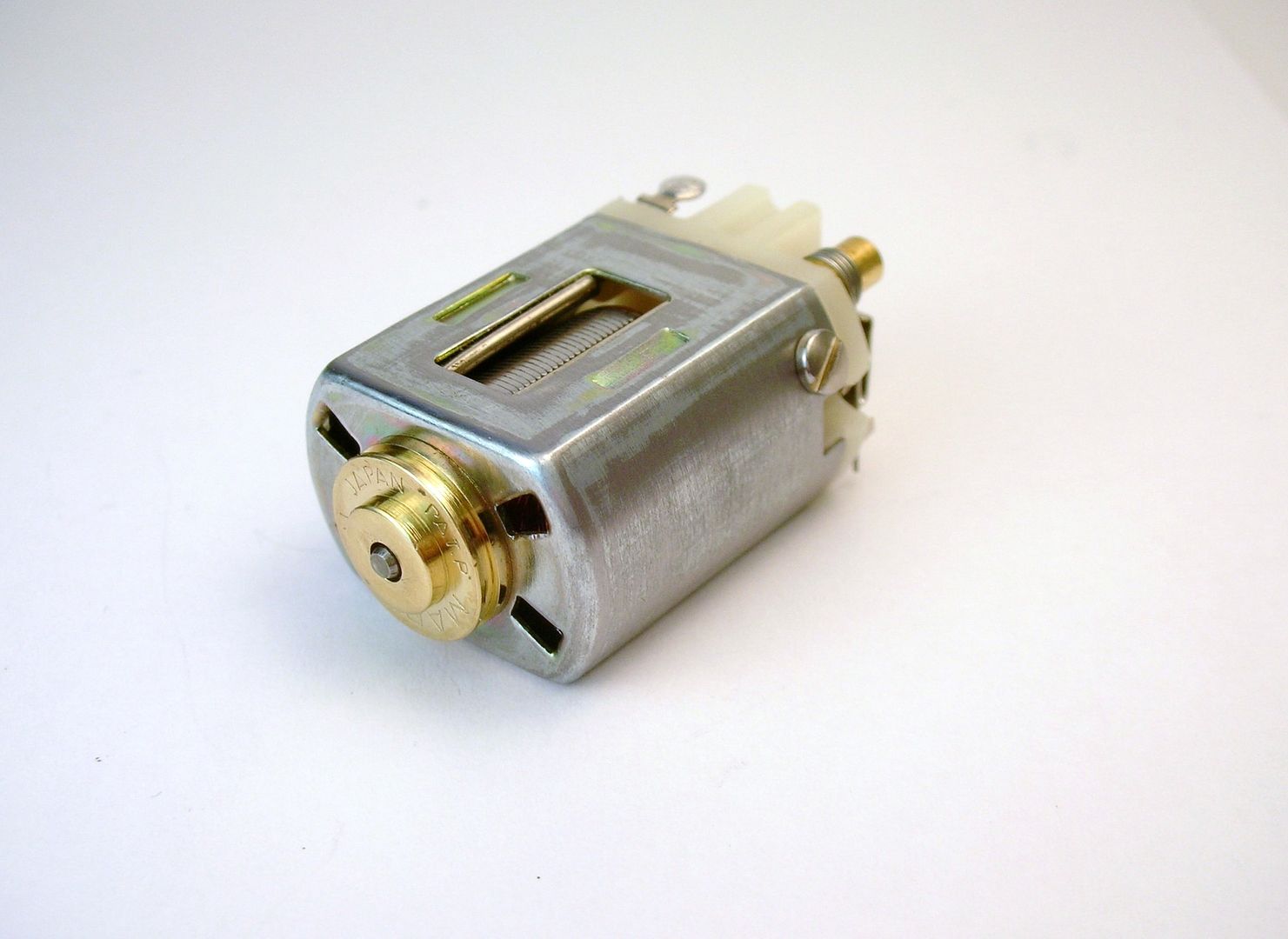

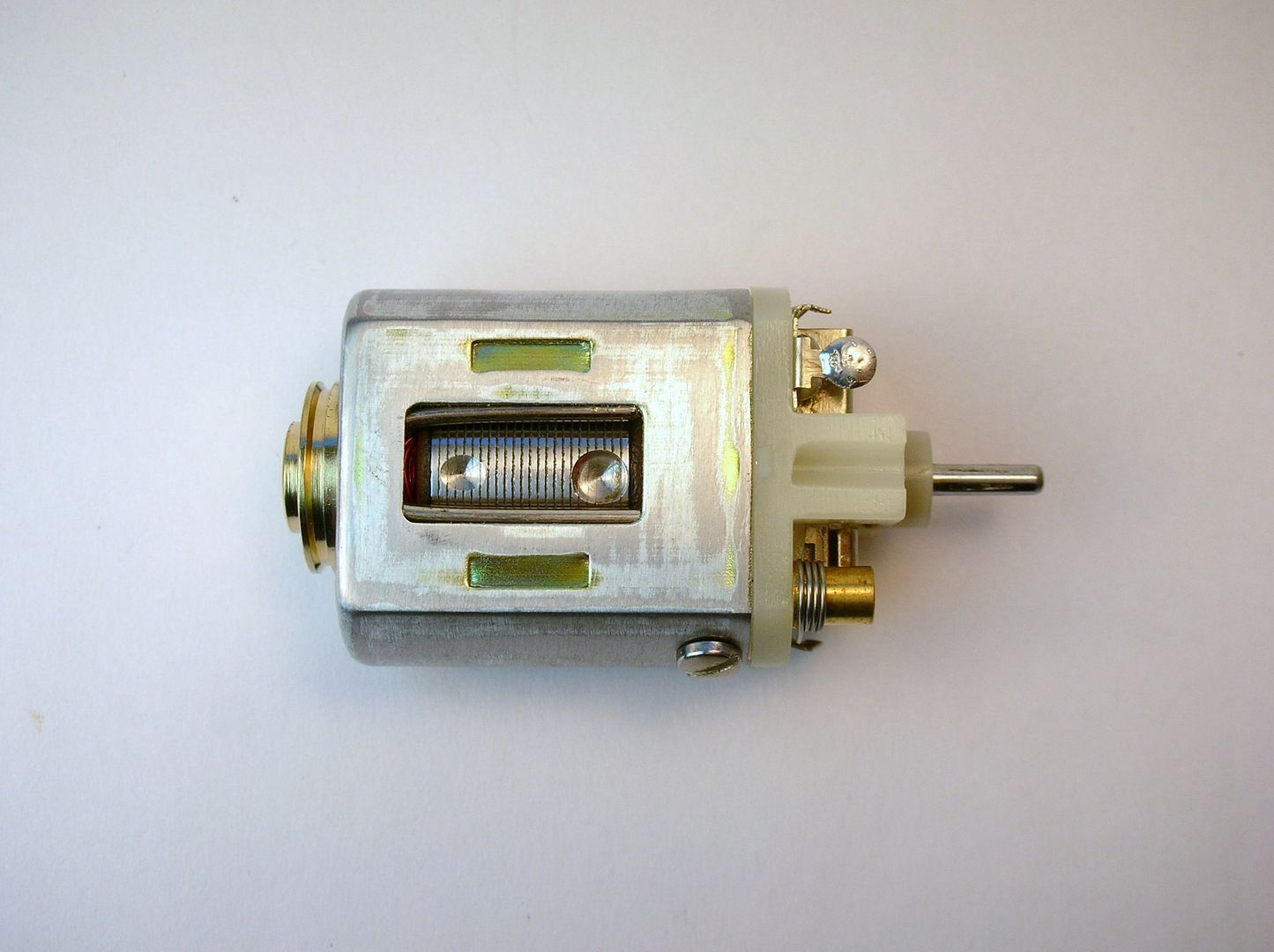

Here's a new old stock (NOS) Mabuchi "gimbal bearing" can:

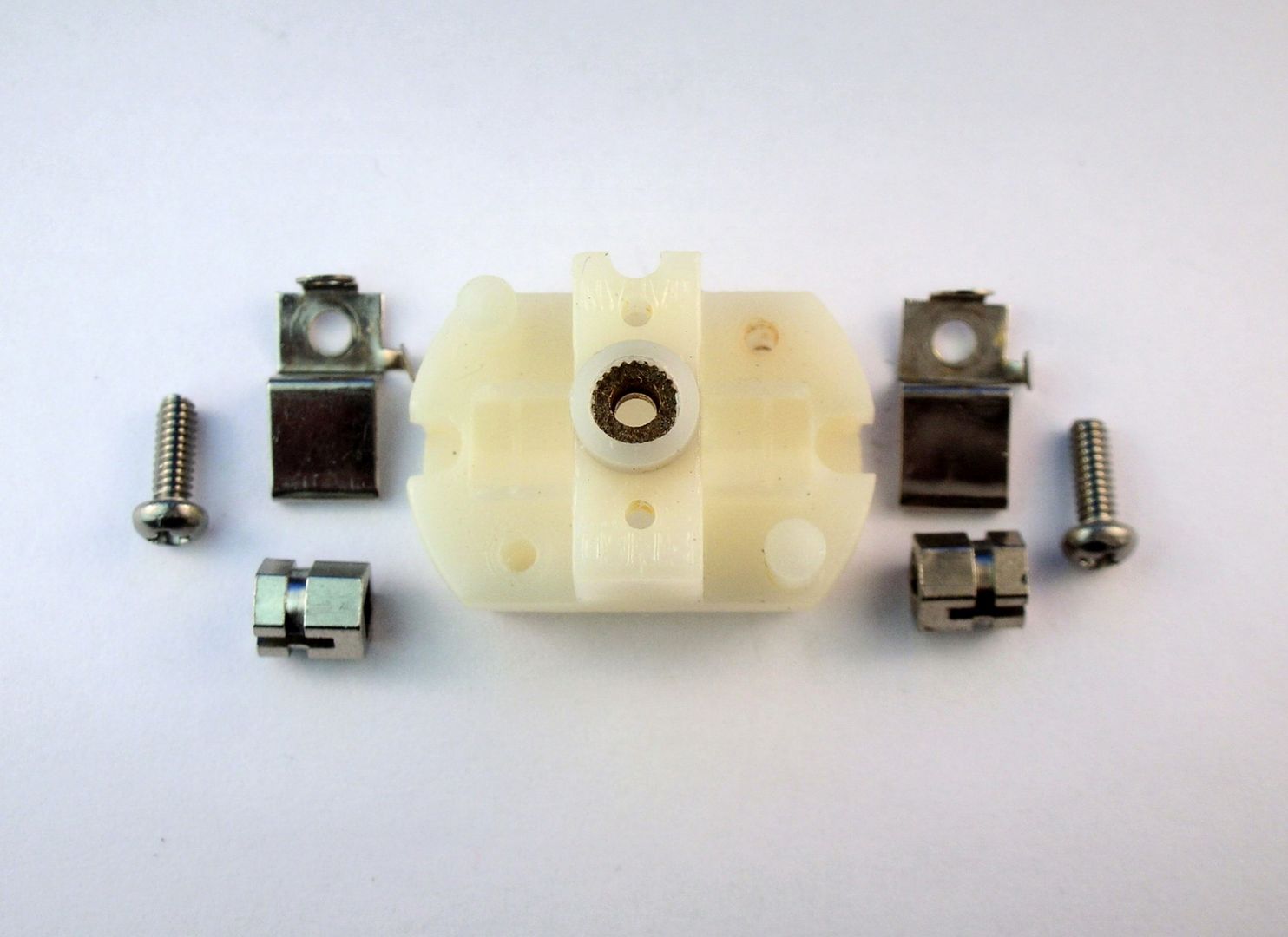

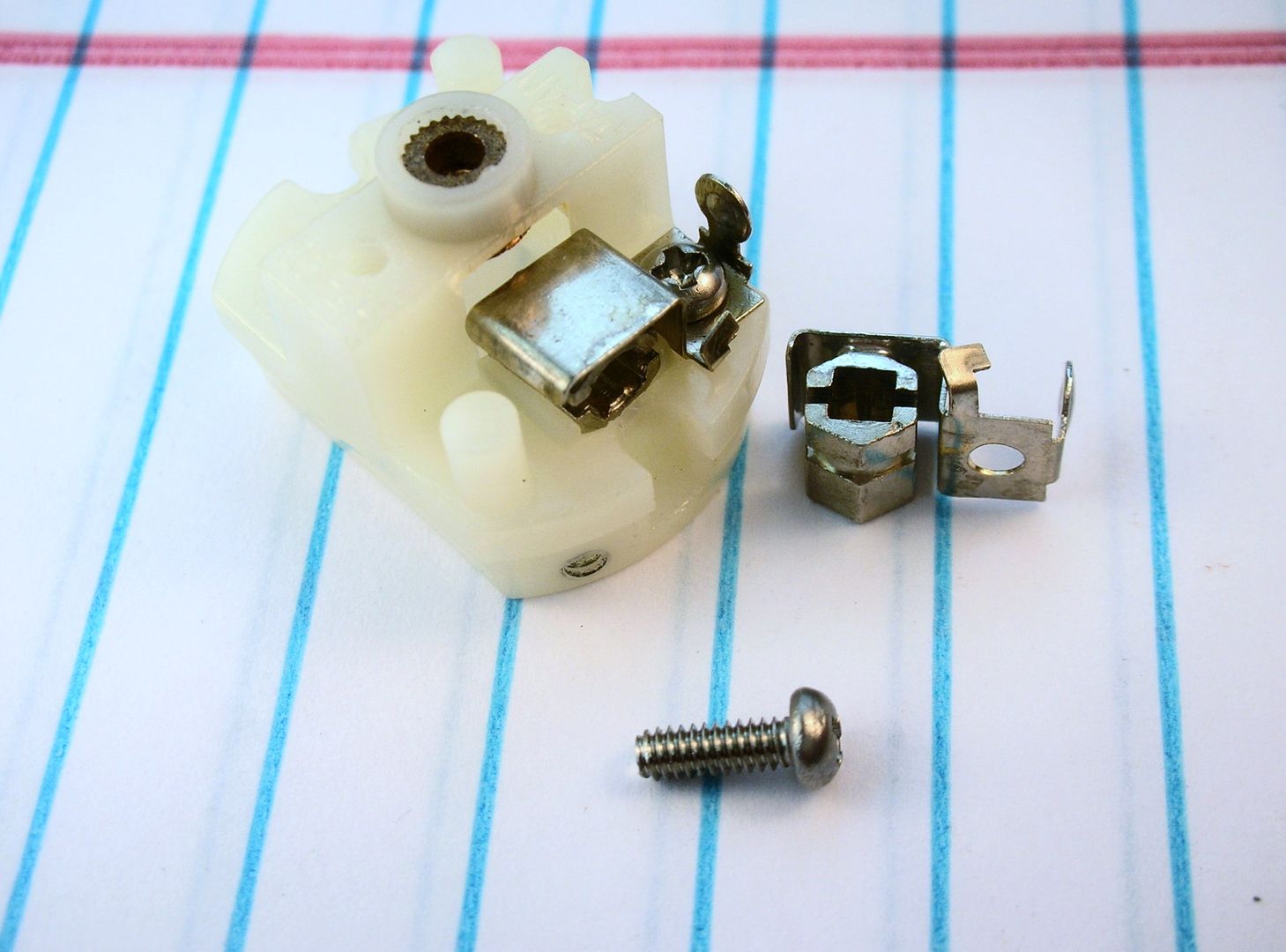

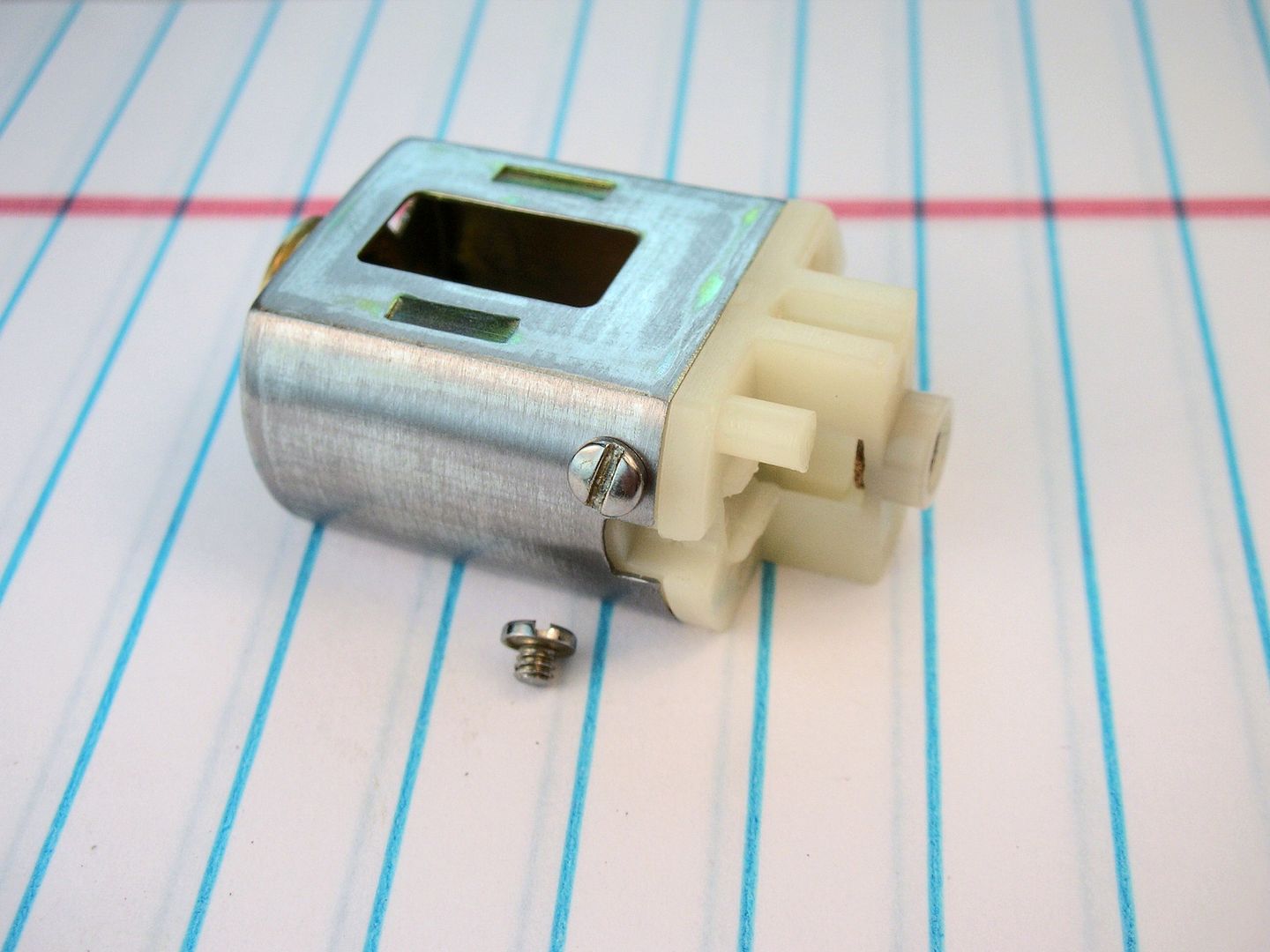

A NOS Mabuchi endbell and hardware. The self-tapping screws are going to be replaced with machine screws so we don't get any splitting of the 50-year old plastic:

For endbell mods we have talked about soldering the brush holders to the brush hoods and installing spring post protectors.

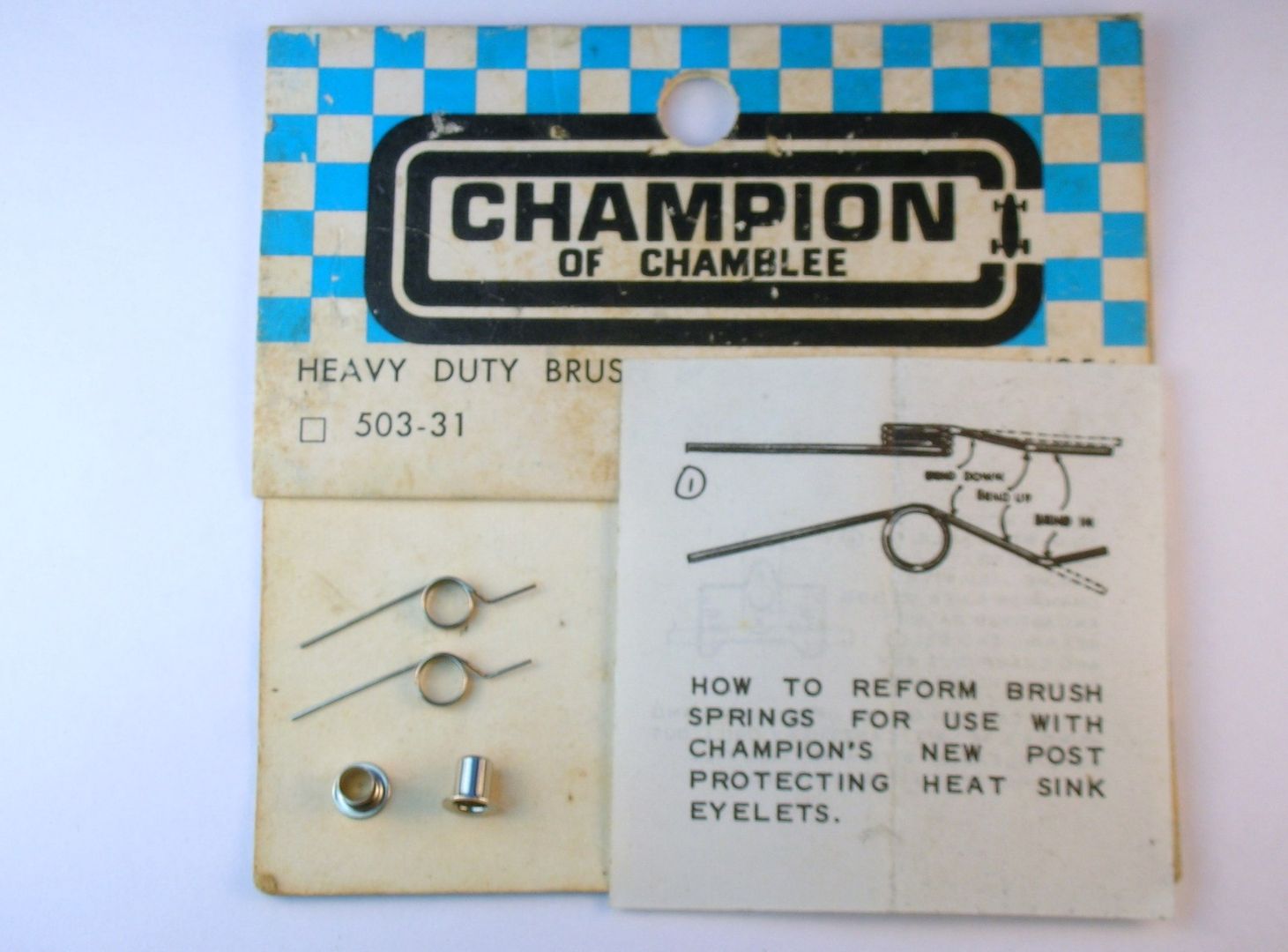

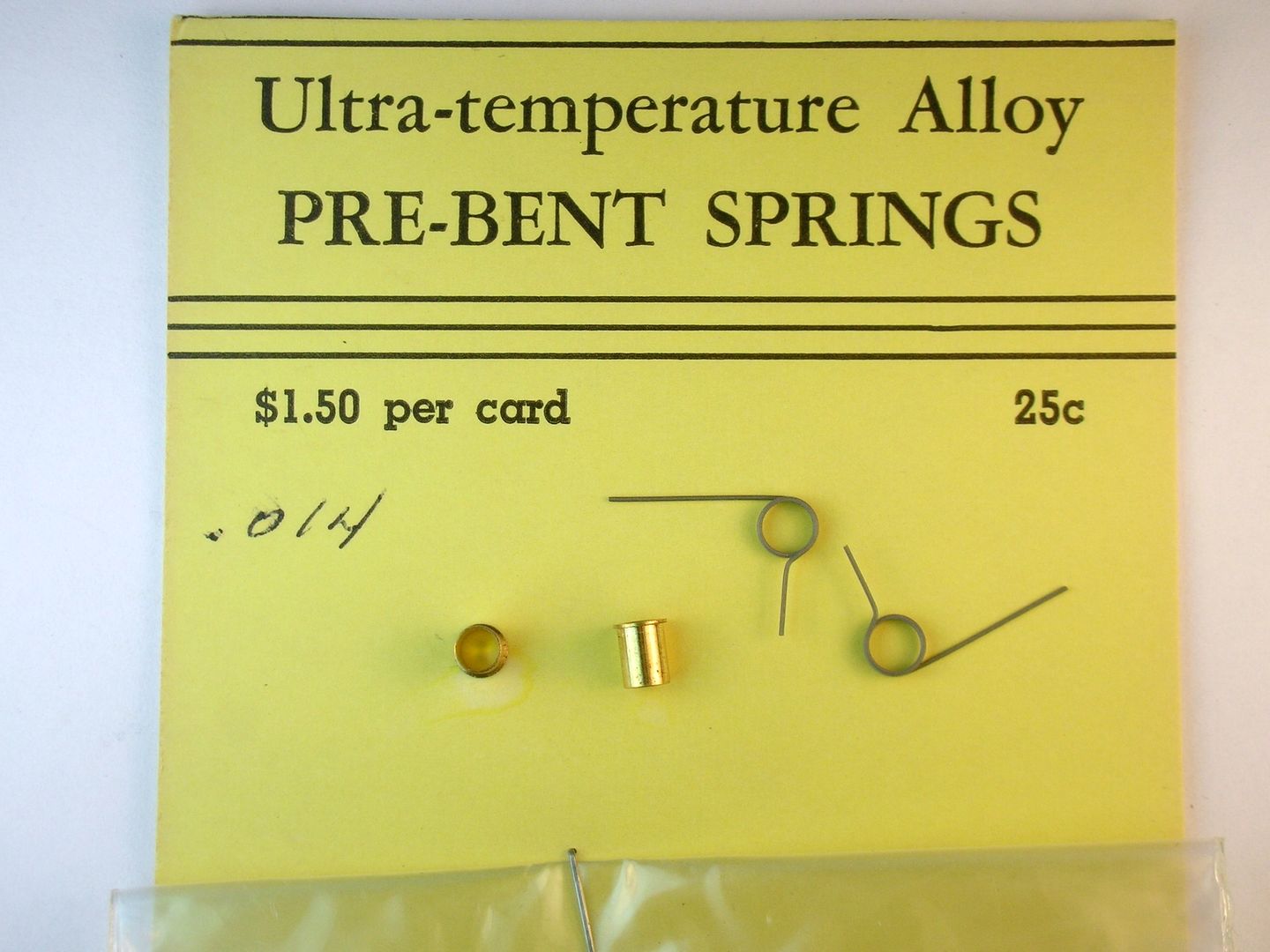

Here are a couple to choose from. First up are heavy duty brush springs and post protectors from Champion:

Next are the same items From Certus:

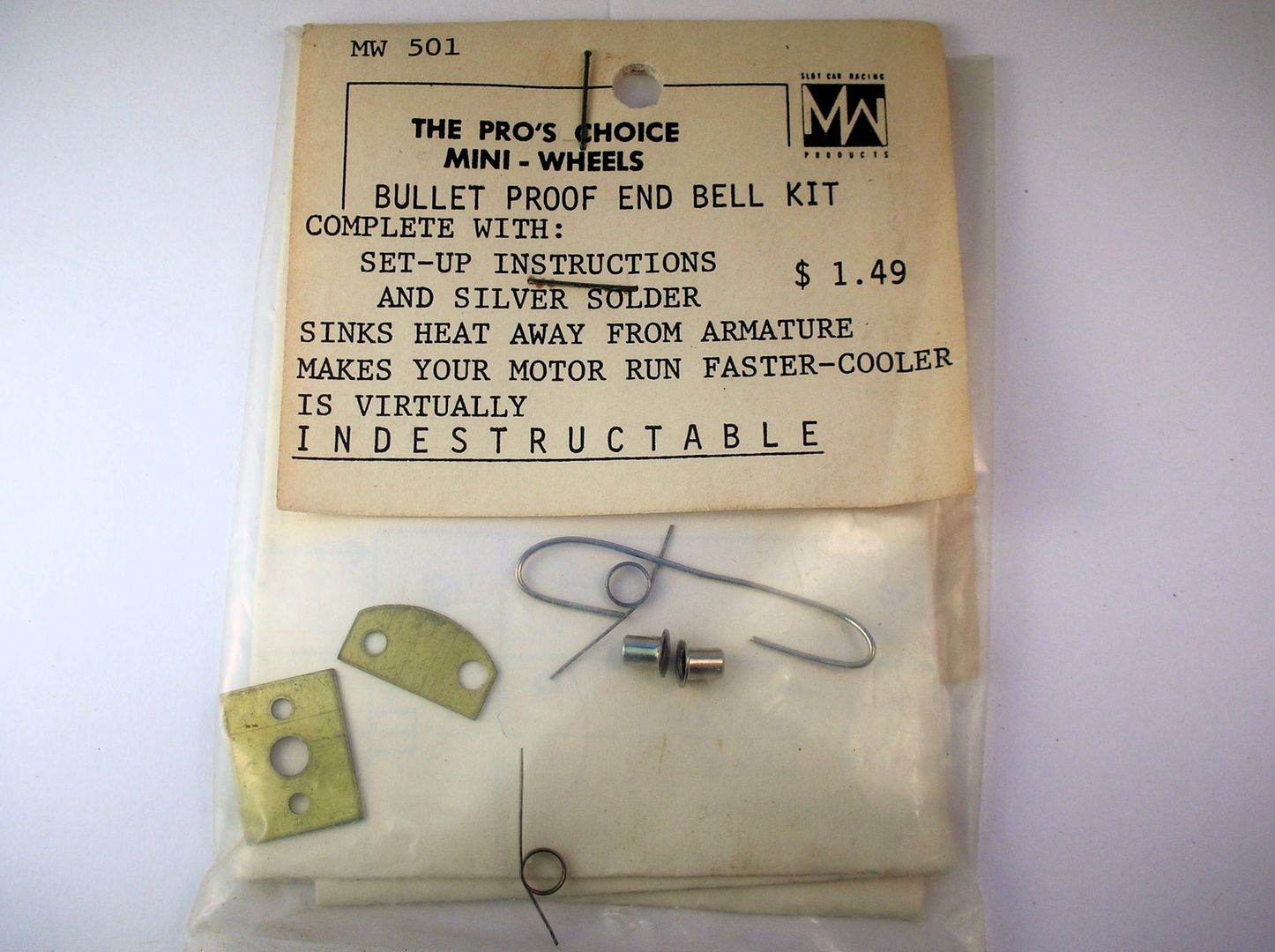

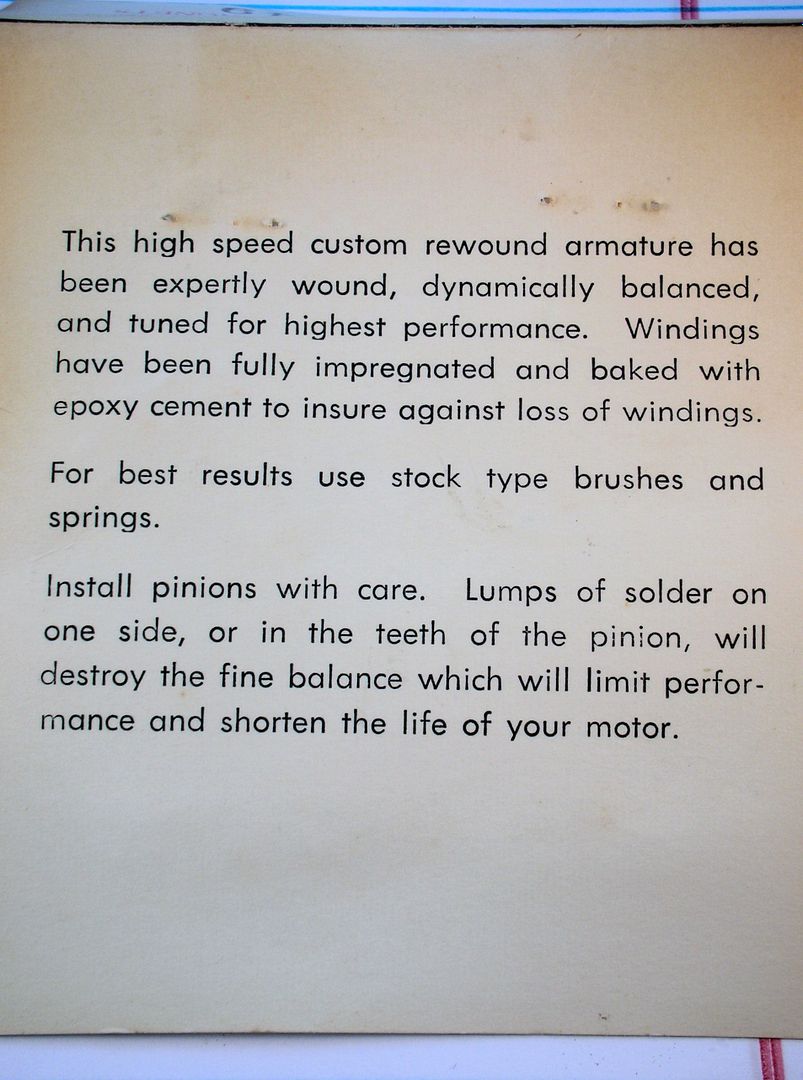

There is also the super duper bulletproofing kit from Mini-Wheels. The instructions are dated 1967:

There is also the "shunted brushes" possibility. I know that Versatec used them early on in their SS101 motor. Mura, I believe, repackaged them and sold them for 16Ds. But if these Cobra pieces were available to you and if you used them at the end of 1967.... ![]() (shown to the right are standard 16D brushes).

(shown to the right are standard 16D brushes).

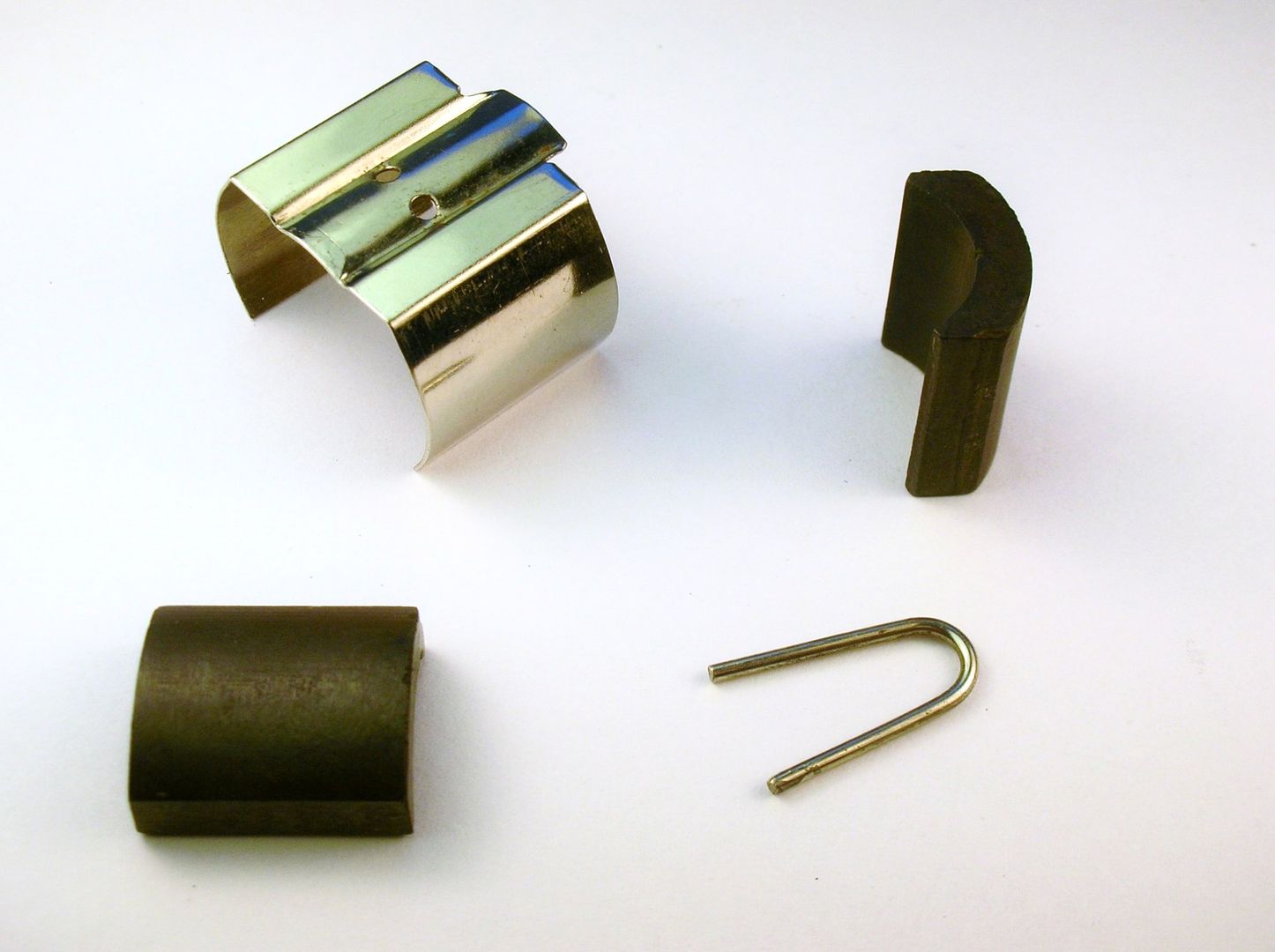

Arco magnets with shim:

The heart of the beast is the armature. Howie and Sandy often wound their own arms in this time frame. I showed Howie this arm for the project:

This early arm has the thick laminations with fiber end plates and a Kirkwood comm with soldered (not welded) wires. Here's Howie's earlier thinking on this arm:

... He [Sandy] was also telling me he had one one of those Thorp arms in the Sandy's sidewinder F1 car and won with it.

OK, I wish we had the entire 1968 Auto World catalog to choose from but... ![]()

- miko likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#86

Posted 29 July 2015 - 06:07 PM

Ask Howie if he remembers using one of the endbells Bob Emott was building at the time.

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#87

Posted 29 July 2015 - 06:09 PM

Hi Tony.

Boy, I'd love to see one of those.

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#88

Posted 29 July 2015 - 07:00 PM

Nice shiny new parts. ![]()

That Mabuchi can sure is a blank "clean" canvas! Don't see many in that bare condition.

Tony and Rick, what was a Bob Emott endbell like? Sounds a rare performance beast indeed!

#89

Posted 29 July 2015 - 07:22 PM

Those Champion springs are gonna be pretty strong once loaded up, or is it an illusion, Capt. Rick?

Paul Wolcott

#90

Posted 29 July 2015 - 07:46 PM

They had flat plates and the brush hoods were made from channel tubing soldered on. That's all I remember.

Philippe may have one on an old Kean motor.

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#91

Posted 29 July 2015 - 08:09 PM

Those Champion springs are gonna be pretty strong once loaded up, or is it an illusion, Capt. Rick?

No illusion, Pablo, they're strong alright. I can tune them with a bit of bending if needed, and if Howie wants to use them.

- Pablo likes this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#92

Posted 29 July 2015 - 08:25 PM

I think that the Emott endbell is later with Kean.

At this race i did the whole motor as usual. Nobody was lending me any winning motors. Good motors were freaks from a batch of also-rans. I was winding them in my bedroom in my mom's apt and balancing them on razor blades. Epoxy them with Acraglass made for guns and bake them in the oven. I used the transformer from my AMT Model Motoring set at home for my entire slot career back then.

- Pablo, Gator Bob, Samiam and 1 other like this

#93

Posted 30 July 2015 - 06:20 AM

Ok wasn't sure I know when I first met Bob at Nutley he had them on his motors and Wayne Williams when he was working at Nutley was making them to sell over the counter.

Anthony 'Tonyp' Przybylowicz

5/28/50-12/20/21

Requiescat in Pace

#94

Posted 30 July 2015 - 11:04 AM

OK, here's what we're going with from the above items:

Mabuchi "gimbal bearing" can

Can painted gold, I'm painting last so Howie can still change his mind (Any color is OK with me) ![]()

Mabuchi endbell with the brush holders and hoods soldered up

Endbell mounting screws on the sides of the can, not the top and bottom

Champion Arco magnets with shim

We're not using these items:

NO Mini-Wheels bullet proofing kit

NO shunted brushes

Things undecided:

Champion chrome "eyelet" style spring post protectors or the original Dyna-Rewind style machined brass jobs.

Brush springs

Breaking news:

I've just paid too much for a different armature. It's exactly the same as the pictured Thorp "Russkit 23" style arm but this one is made for the gimbal bearing can Thorp calls "CM150 Type".

Time to start building...

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#95

Posted 31 July 2015 - 05:17 PM

The new Thorp arm arrived and she's in really great shape. Almost no corrosion which is great:

I didn't even diamond turn the comm. Just polished it with some 8000 grit cloth. I'm guessing this is a Mabuchi blank judging from the scoring on the shaft to hold pinion gears in place:

Thorp instructions on the back of the package are interesting. Don't use stock magnets but do use stock brush springs. I'm going to take their advice:

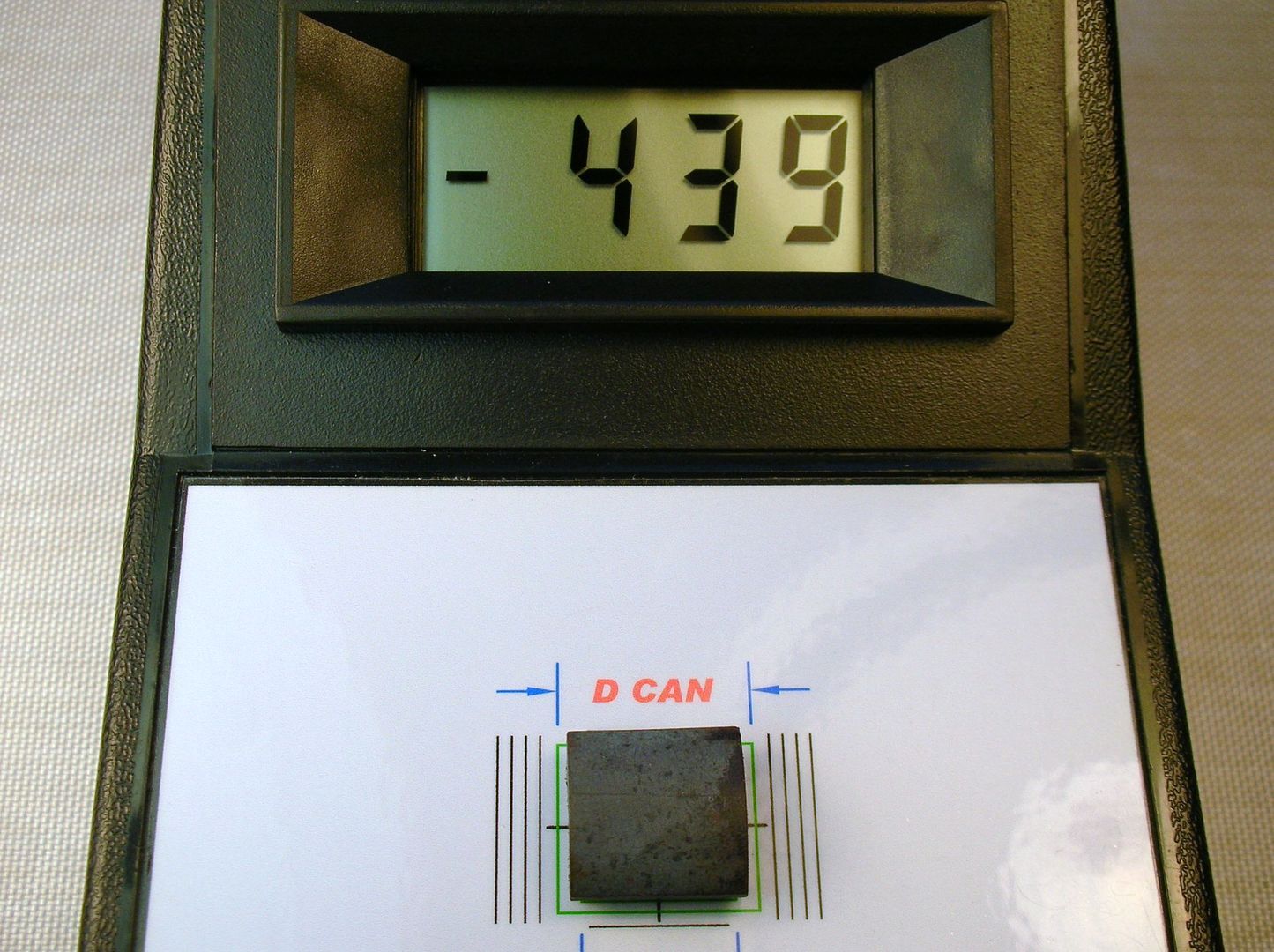

Here's the gauss reading of a good stock Mabuchi magnet:

Here's the gauss reading of an Arco magnet going in this motor:

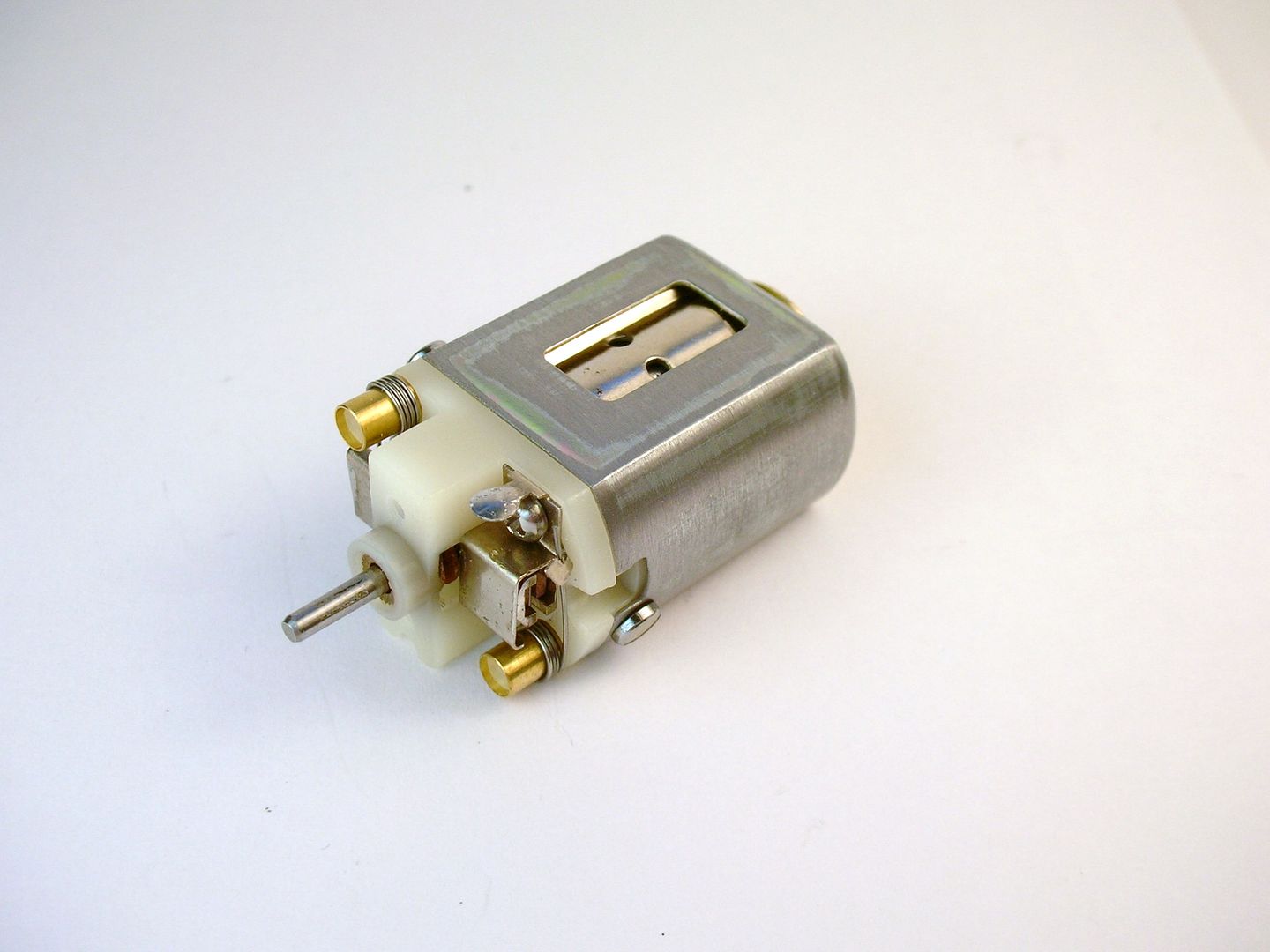

The endbell hardware gets soldered up, attached with a stainless steel machine screw and the bearing epoxied in place:

The floating gimbal bearing is also epoxied in place with Devcon Two-Ton epoxy:

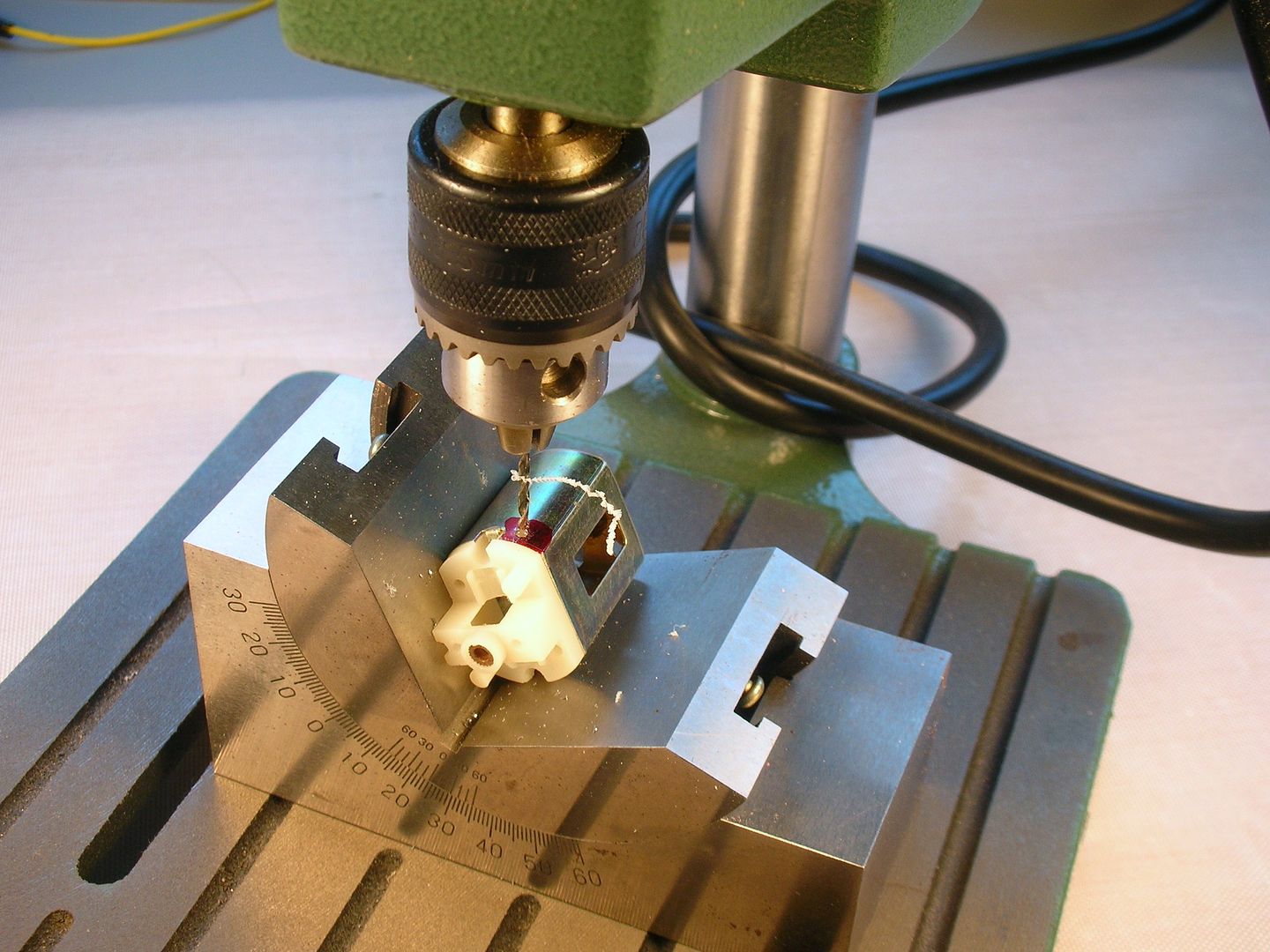

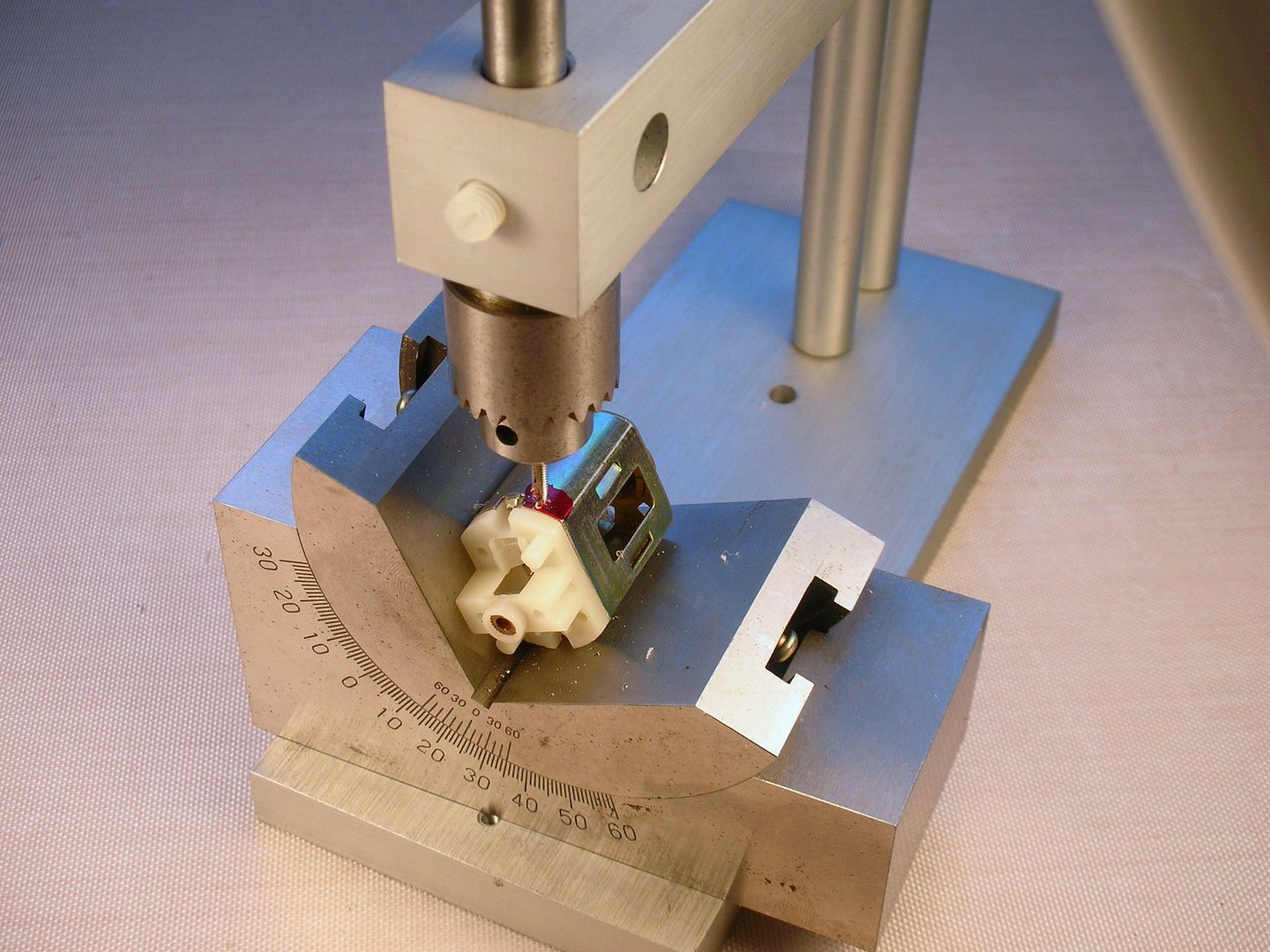

I love my "Toys for Retirement". I used to drill and tap the endbell mounting screw holes by hand with a pistol drill and a hand tap.

Not any more... ![]()

My results doing this by hand and eyeball were not so good. Now they are nice square screw installations done quickly and easily:

The finished motor "in the white". It will be painted after the bare can and endbell have done their duty as a "jig motor" to build the chassis with:

I used the brass spring posts because they slip on and off. The Champion pieces are a press fit. Howie can still choose which he'd prefer:

I followed Thorp's advice and used light brush springs. The motor buzzes up nicely and draws less than 1 amp. I can always change to heavier springs if testing dictates:

I love the big honk'n magnet clip Champion used. I added .004" shim stock behind the Champion shim per Bryan Warmack's motor build article posted above. The air gap is now just over .530" and the arm is about .510".

Onward...

- Cheater, endbelldrive, slotbaker and 1 other like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#96

Posted 31 July 2015 - 05:39 PM

Perfect, Capt. Rick! Almost as good as Howie in his room back in the day. ![]()

- Howie Ursaner likes this

Paul Wolcott

#97

Posted 31 July 2015 - 06:25 PM

Yeah, I use a ready-wound arm. Howie winds and balances his own.

I use a drill press, adjustable angle block and taping fixture to drill the endbell screw holes. Howie does it by hand with a Dremel sitting on his bed at his mom's house.

All I can say about my approach to this build is, "A man's got to know his limitations." ![]()

I am having fun though! ![]()

![]()

- Cheater and Howie Ursaner like this

Rick Thigpen

Check out Steve Okeefe's great web site at its new home here at Slotblog:

The Independent Scratchbuilder

There's much more to come...

#98

Posted 31 July 2015 - 06:37 PM

Anybody who takes the stage and sings "I'm Eighteen" by Alice Cooper has my respect 100%.

- Howie Ursaner likes this

Paul Wolcott

#99

Posted 31 July 2015 - 06:43 PM

Good choice, Rick. I melted plenty of endbells and solder on the comm tabs using stock magnets back then! Mags weren't strong enough.

Most of the hop-up 16D brushes at the time had a high silver content. This made them soft and combined with the higher tension springs, the comm slots would become clogged very quickly.

Keep up the great work.

Sano Dave

1953-2015

Requiescat in Pace

#100

Posted 31 July 2015 - 07:19 PM

Anybody who takes the stage and sings "I'm Eighteen" by Alice Cooper has my respect 100%.

For me, that would have been almost 50 years ago, but I can't sing anyway. ![]()

Rick, I might suggest that you run that arm a bit (in another set-up) so it gets hot and goes out of balance. Then send it out to the reconditioner of your choice for rebalancing. The epoxies of old weren't nearly as stable as today's are.

I intend to live forever! So far, so good.