Thanks for the replies. It might have been mdf I am not sure when it took over from particle board. I always took my slot box with some cars in it to do installs. I really did not maintain those test cars very well but it was always a shock when they go down a main straight and do not turn. Once I found the blade still in the slot only 5 feet after the lead on. Still made it all the way to the bank before the ultimate launch.

Today I took the track over to my oldest son's place and we set it up in the garage. I am going to clear coat with solvent base Verathane for the base. I have to order the epoxy in, Canadian Home Depot stores do not stock Rustoleum 5300 series water based epoxy and I will find out tomorrow if I can get any at all. I may have to go with a Sherwin Williams oil based epoxy, good stuff I have used before but not my first choice.

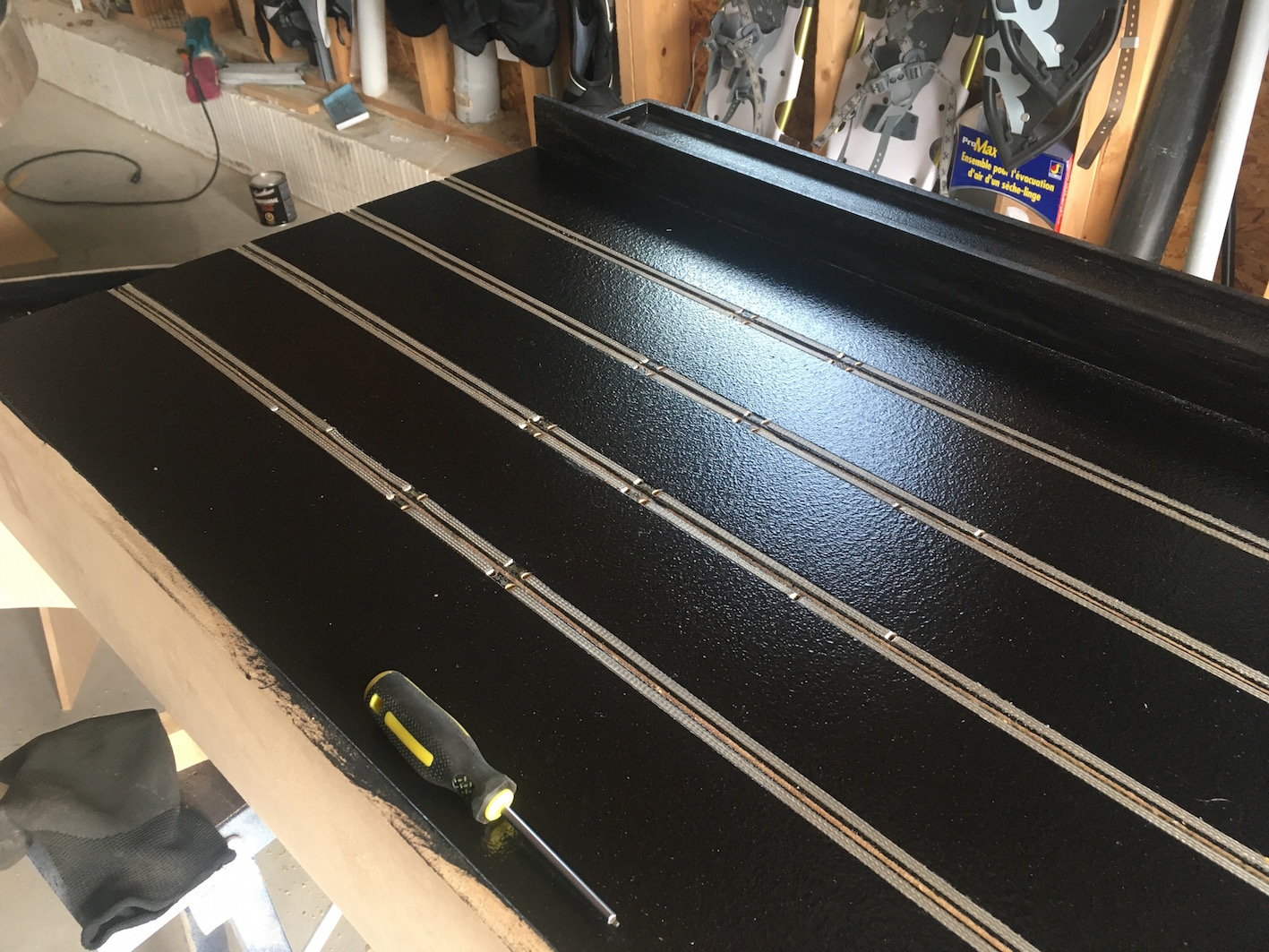

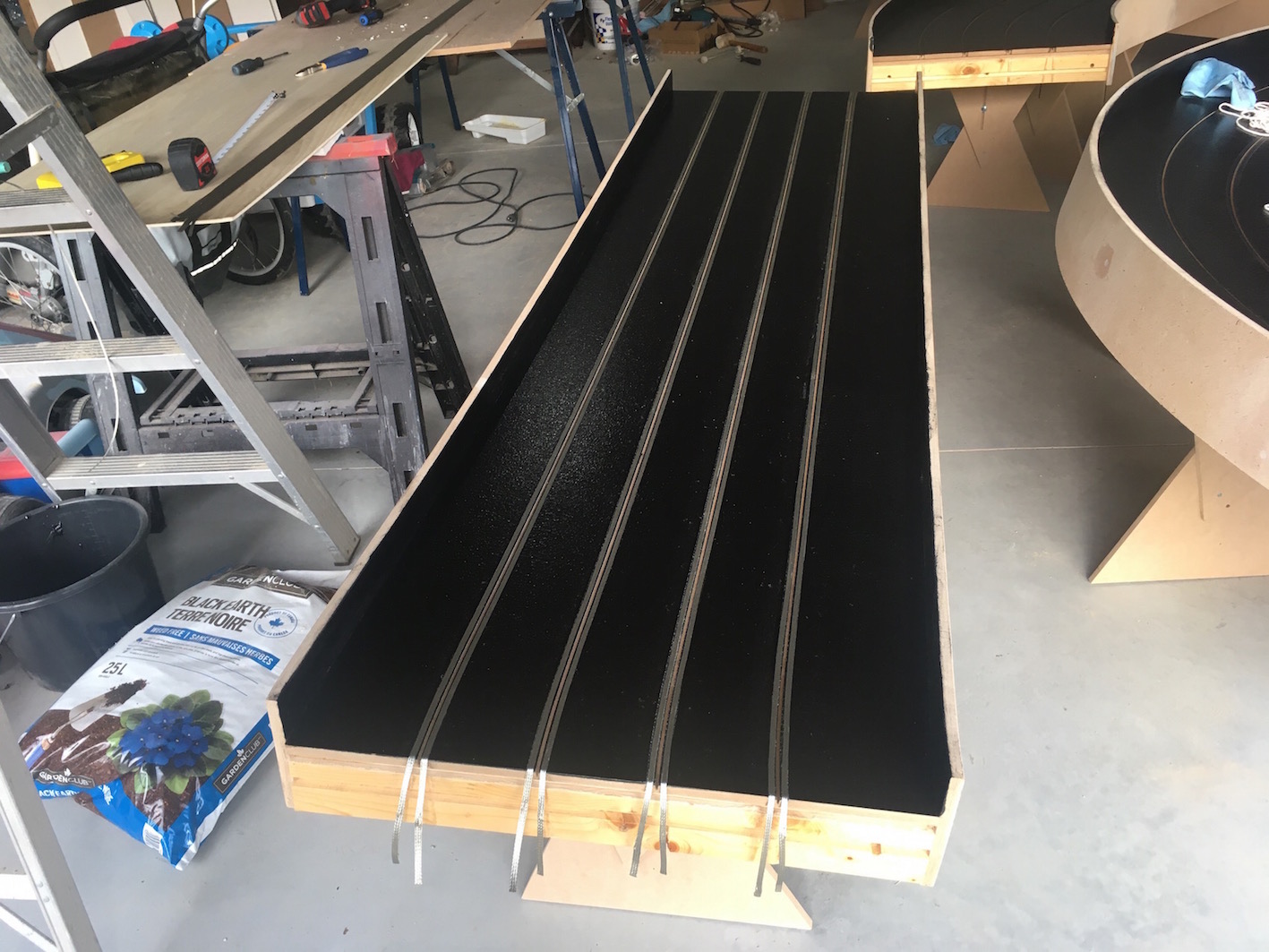

Track going back together:

Forgot to get a pic with it all together but I made a short video I will post later.