Thanks Ron and everyone else for the likes and replies. I am really enjoying doing this thread, nice to share everything.

I dug out our old side wall trimmer today. This is something Brian Crosby and I came up with together to speed the process of trimming the top and bottoms of sidewalls. For cutting the bottom of the walls it works well. For trimming the tops of the walls it works well too but it is a little dangerous. Actually a lot dangerous. I will show some pictures of it but I will be using the router off my circle cutter to trim the tops of the walls.

The board marked trim jig rides on the track surface while the blade of the saw trims the top of the side wall. There is nothing to protect the operator from the exposed spinning blade. I never allowed an employee to use this tool. I never hurt myself with it luckily but really not that eager to tempt fate again. It was much quicker than a router but I don't need to be in a big hurry these days.

The attachment for trimming the bottom of the wall is much more civilized. It just hangs off the top of a trimmed wall and the operator is protected by the sidewall and the saw guard. When going around the inside of a corner you have to let more blade out but nothing can touch you. You have to be careful to make sure the saw does not ride up and ruin the wall but it is fairly stable.

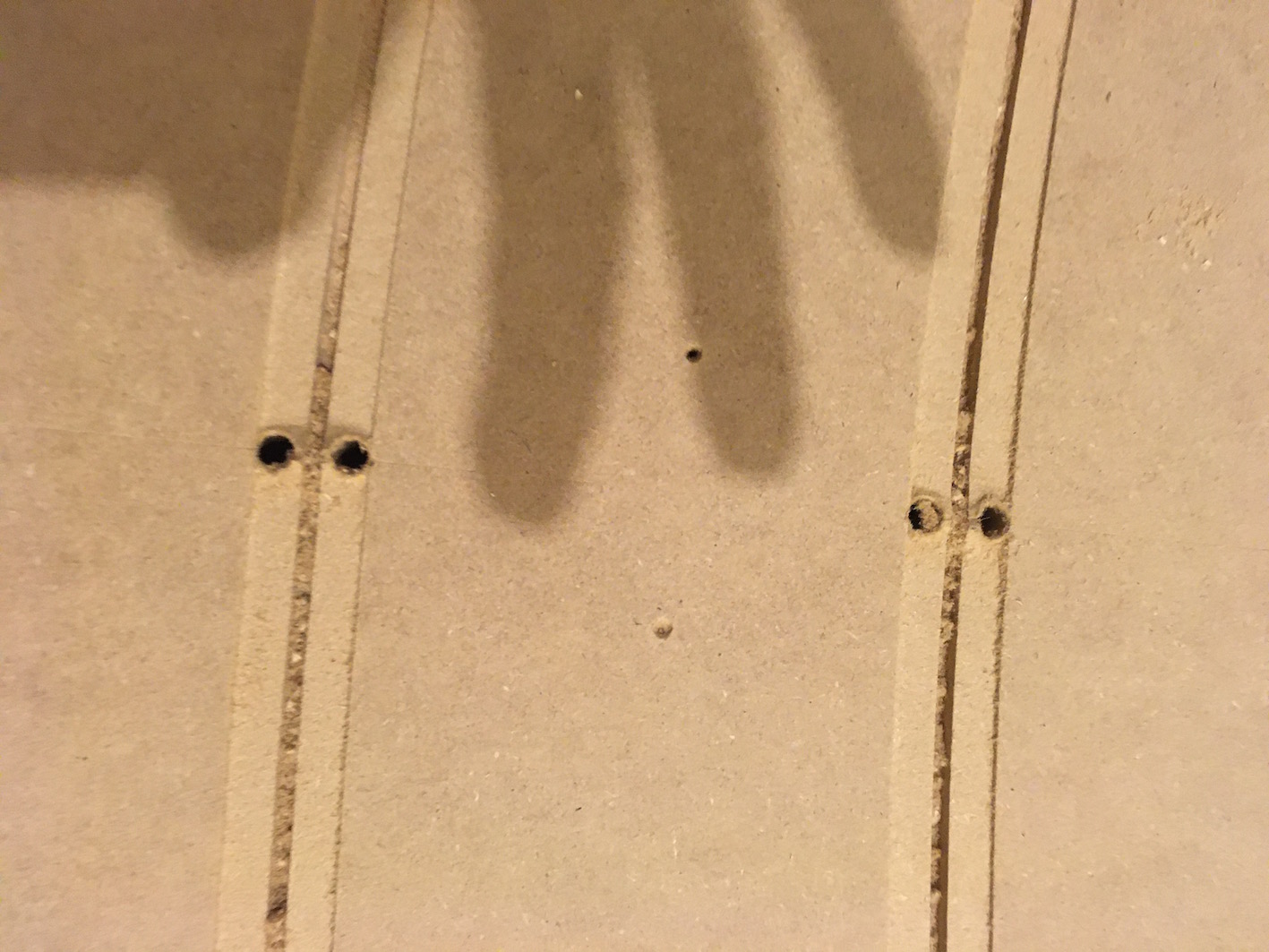

The router that is on the circle cutter cuts a 2" high sidewall with 1/4" carbide tipped bit. I used to have a jig to hang it off the wall to trim the bottom of the wall but it was really hard to keep the cut from creeping up. Normally I would have a dedicated router for top of wall trimming but I only have one of theses routers now. We used to wear out one of these routers every year.

I have a lot of stuff to clean up in the morning but I hope to be trimming walls by the afternoon and I will try to make another video.