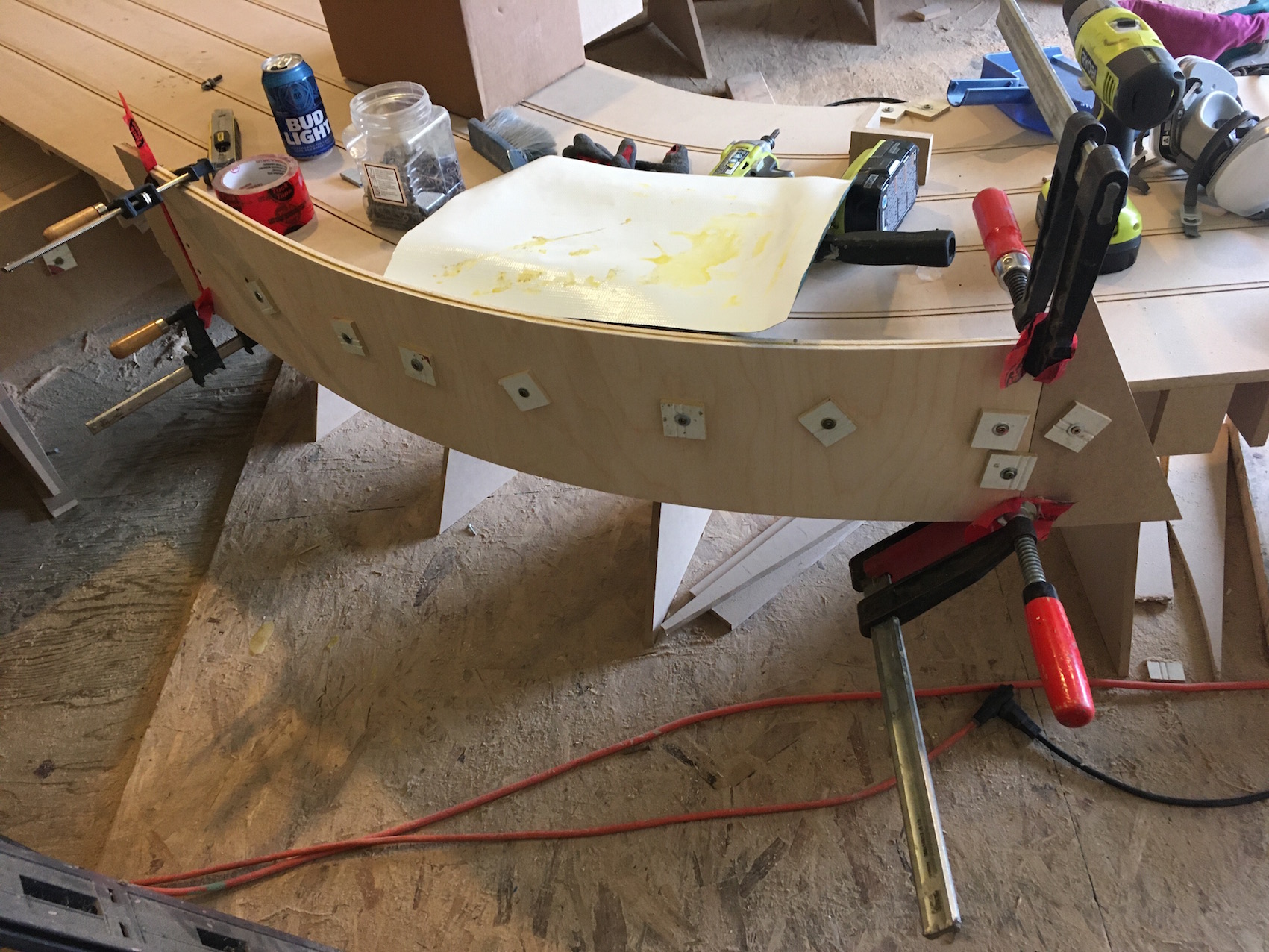

This track was really easy to bolt together. First I shimmed under the outside of each corner leg, about 1" under the donut legs and 3" under the 8' bank turn. The track then was already shallow banked before I pulled the main straights together. I used the corner before the under bridge as my bolt together joint.

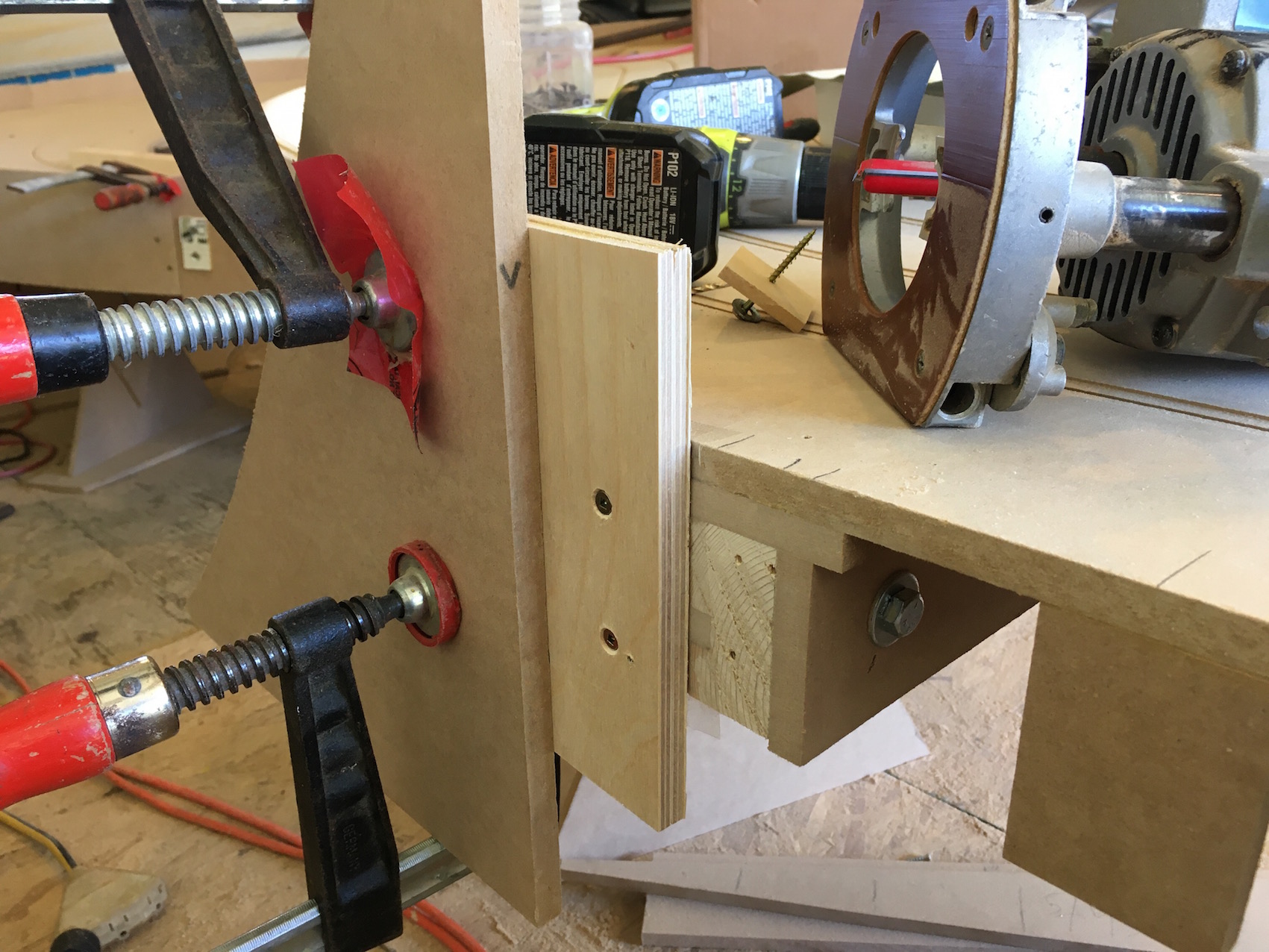

I pushed the corner to the outside with my left leg and pulled the straight in with one arm and got a bolt started. Because the small corners have to be pushed out and the straights get pulled in, on this design they work against each other to hold the banking. So once I got a bolt started I could let everything go and just put the rest of the bolts in and pull the joint together with the bolts.

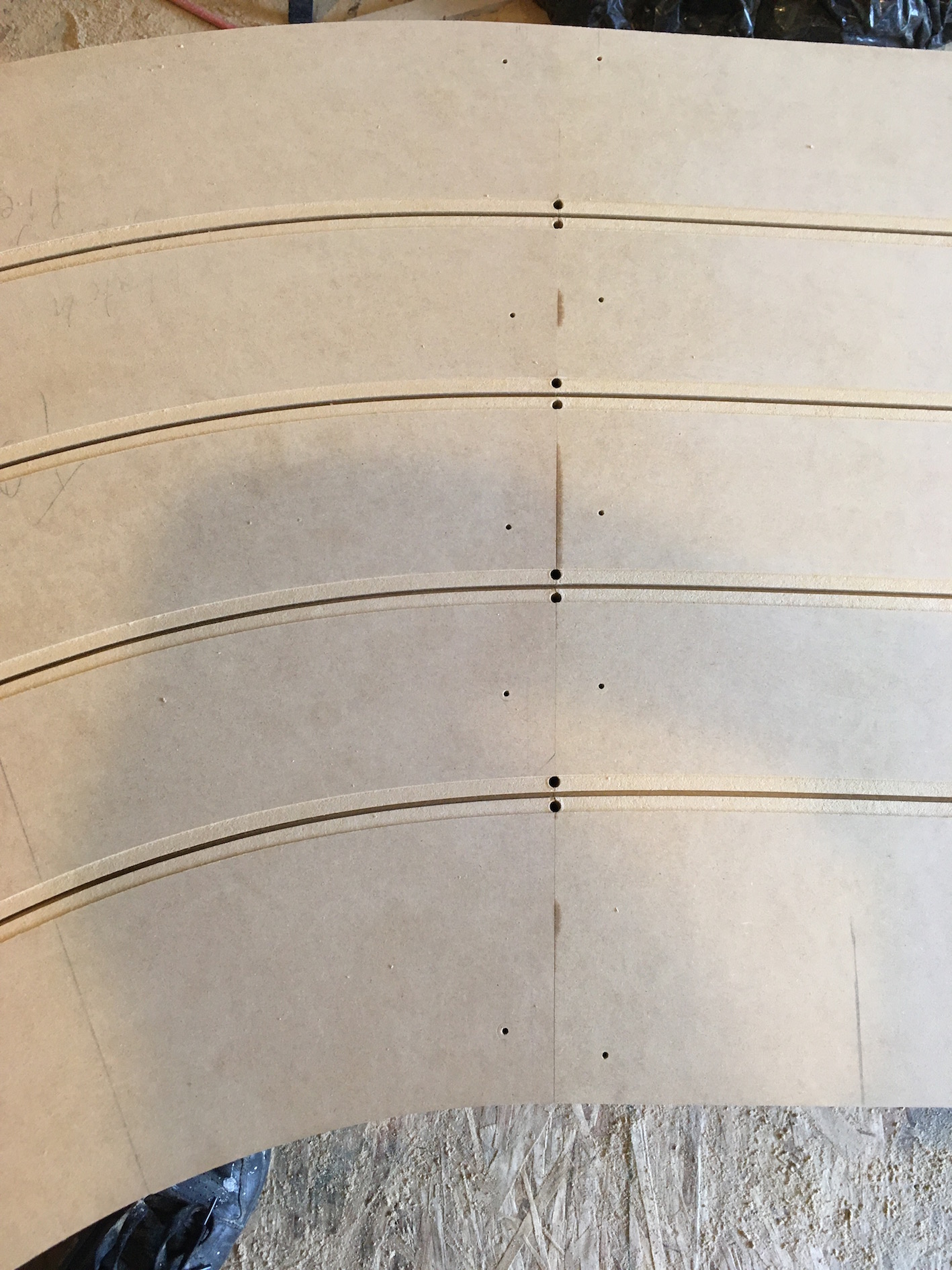

When pulling together the last joint on any track always look at the gap you have when you get it close enough to get a bolt in. A gap on the outside of the corner or a fairly uniform gap not too far apart is what you want to see. A large gap to the inside of a corner means you have a problem, something was cut with the wrong radius or the circumference was calculated wrong. Whenever this happened to me I could always find a mistake on my drawing. Sometimes you can get the track together but usually something is not going to look quite right. Or worst case, you are not going to be able to pull the joint together and you have a big gap on the inside of the corner at the joint. This was a rare problem for me anyways it was always a glaring mistake, very annoying. I developed a good eye for problems, I could tell if a track was not right as soon as it was put together flat with out the slots cut. But by making a good drawing and checking measurements and calculations (self doubt is a good thing) I only had to change things on maybe 4 tracks in my career. The gap as the joint was bolted up:

The joint tightened up