The Ryobi driver and drill set are the newest of the works and we got extra batteries when they were on sale. Why is it that you can buy a new drill with 2 batteries cheaper than 2 replacement batteries? I have thrown a lot of perfectly good drills in the trash because of this.

I've posed that same question on FB.

The only time I ever bought separate batteries was when there was a good sale on the high capacity ones.

They are real nice to have on my chainsaw.

From my experience, the run-of-the-mill Dewalts are not as good as the Ryobis. Or maybe they're just not as good as they "used to be". But we have a couple of Ryobis that have been used at work for the better part of 15 years. Batteries have been replaced along the way, but they've held up. We had a pair of Dewalts....they both crapped out in just a couple of years.

At home, my power tools and yard maintenance tools are all Ryobi, so the batteries interchange. Nice to have that!

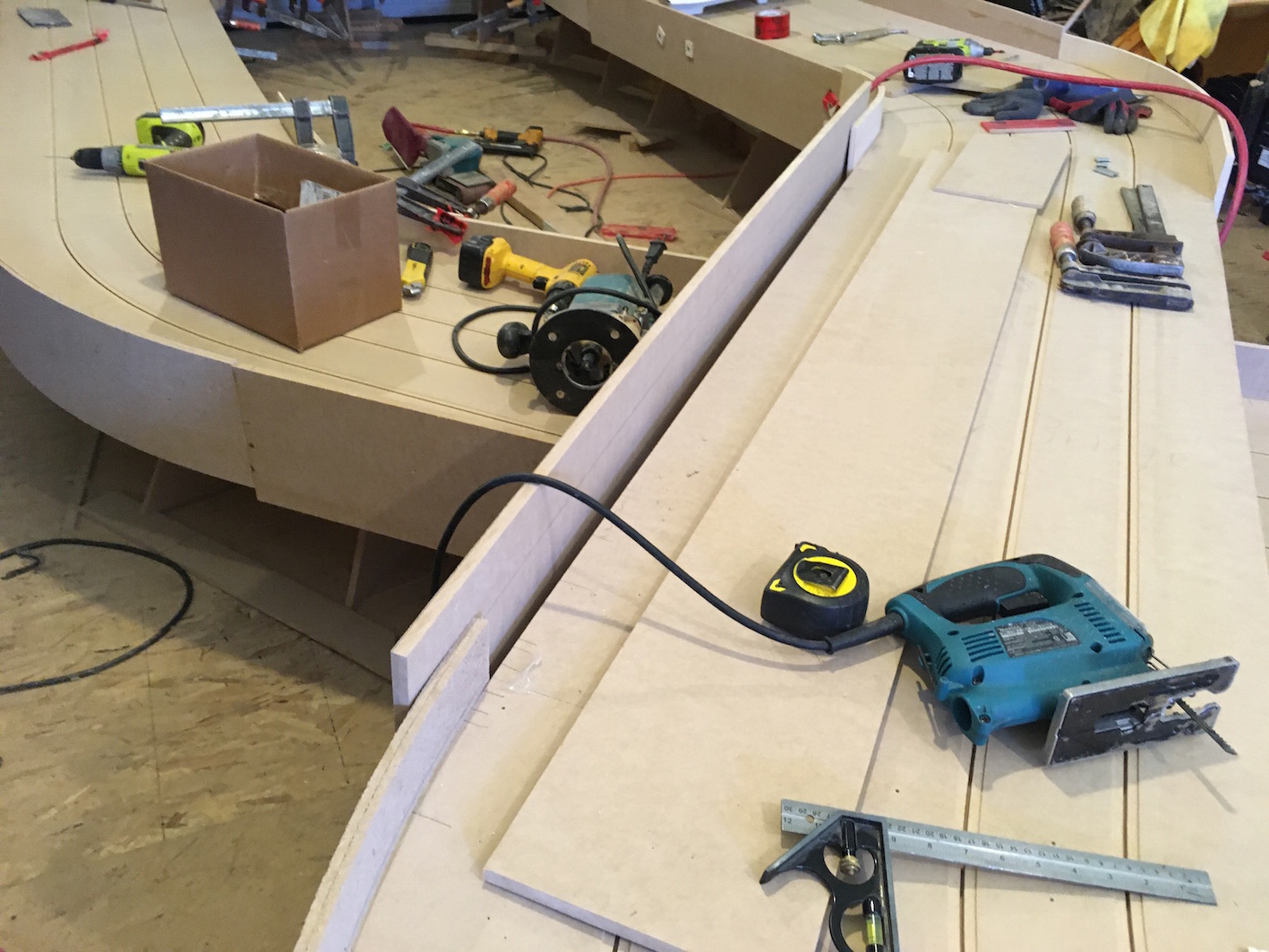

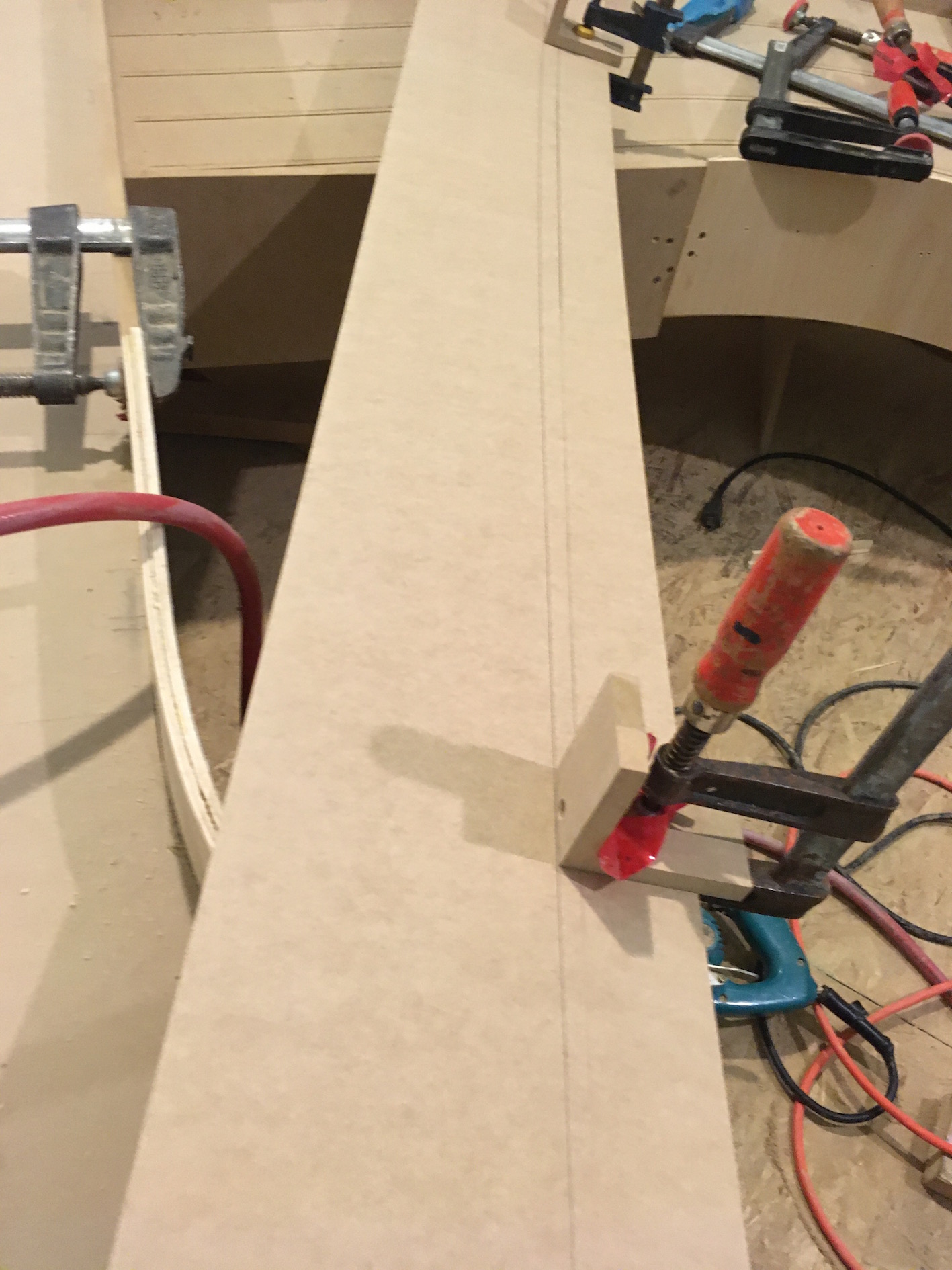

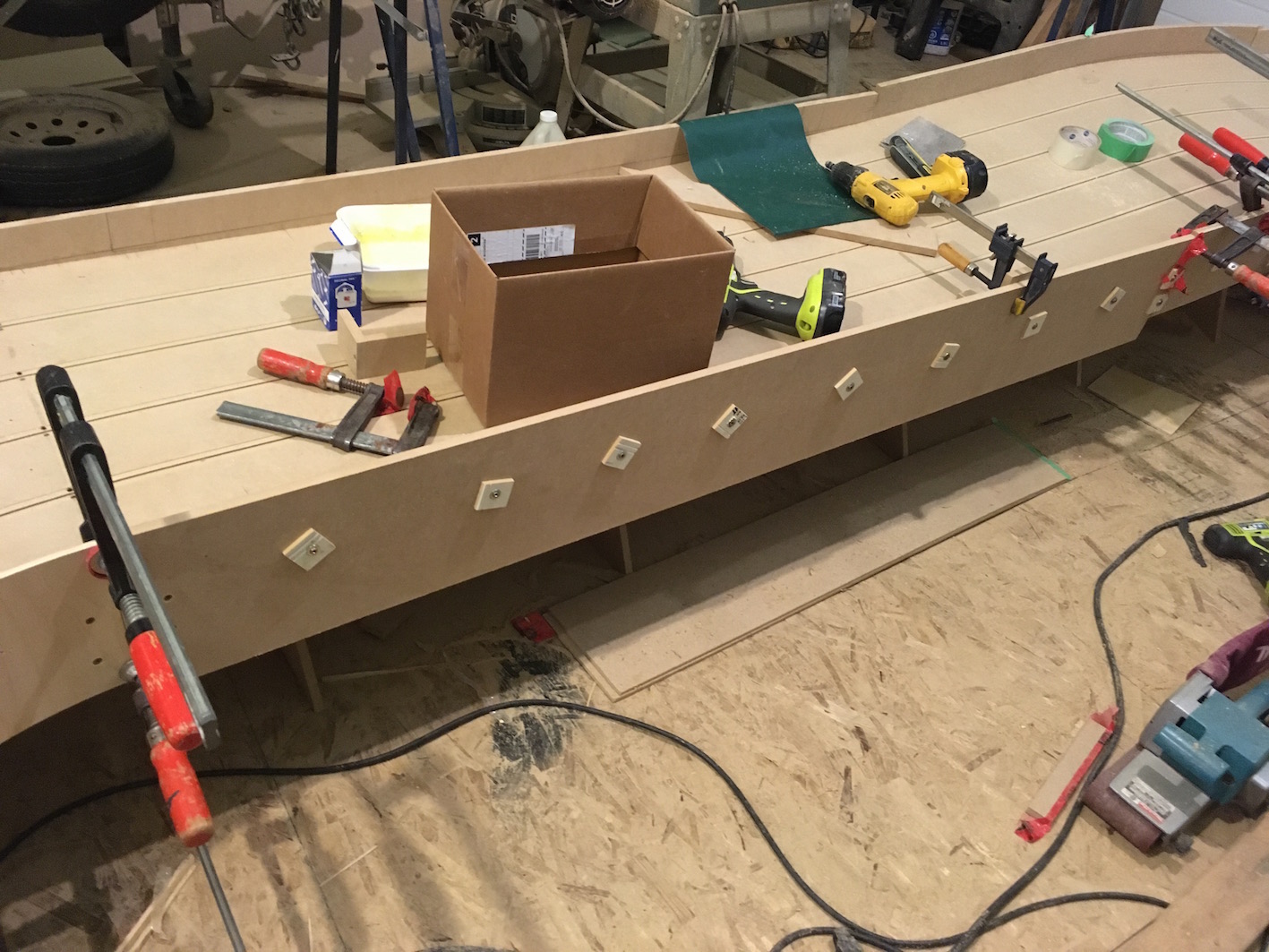

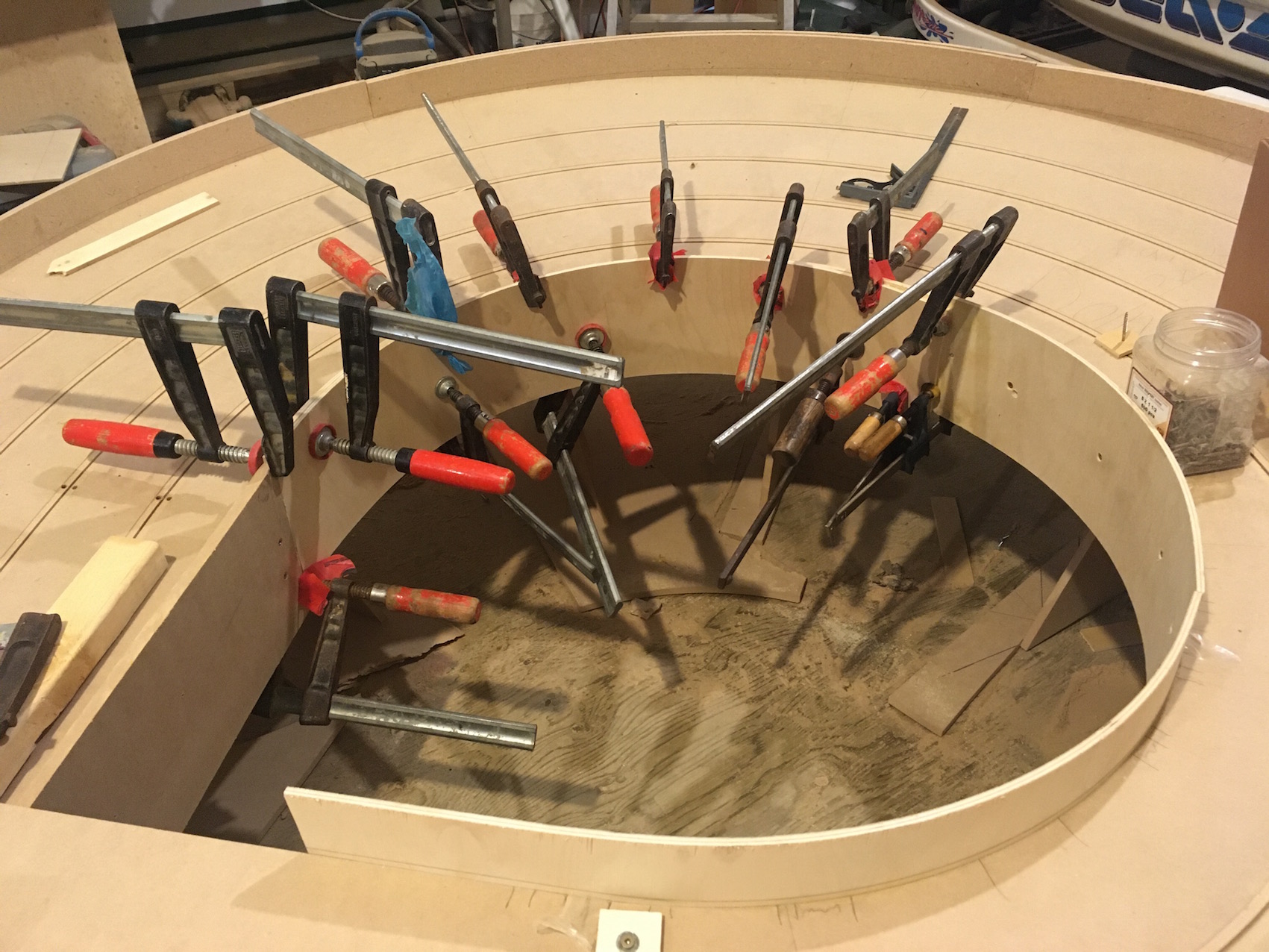

I've been using one of each, the last week or so, wiring up my drag strip.

The Dewalt definitely has a higher quality feel to it.

Also, it's 20V, vs. 18V, for the Ryobi.

When you grab the the keyless chuck, to tighten something in it, it's a good idea to have work gloves on, or it will give you a bit of a friction burn.

That said , I like the Ryobi stuff, and same thing as you mentioned, with also having a blower, string trimmer, and small chain saw, having interchangeable batteries is nice.

And if you throw the drills in the back of your car, and drive them over to a Harbor Freight, it really improves their self esteem, and they work even better. Lol

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559