I am very pleased with my new JK A chassis. I installed a Hawk 6 motor and with no tuning turned very competitive lap times on my home track in Melbourne, Fl. Looking forward to race the car on Sunday in Winter Garden.

New JK stamped chassis

#151

Posted 30 November 2016 - 05:11 PM

GRRR 2016 GT Coupe and Stock Car Champion and Overall Champion

My Series Spring 2016 4" NASCAR, JK LMP State Champion, and Endurance State Champion

My Series 2015 4" NASCAR, GTP and Endurance State Champion

GRRR 2015 4 1/2" and F1 Champion

GRRR 2013 & 2014 Evil Flexi Champion

1968 Cleveland Car Model Series race winner - Tom Thumb Raceway, North Royalton, Ohio

1968 Hinsdale ARCO Amateur runner-up

1967 Parma Raceway Indy 500 Champion

#152

Posted 01 December 2016 - 11:07 AM

My intention here isn't to demean the chassis in any way. It is just to simply state the problem I'm having with mine. I have never had a chassis that once it was straight and flat would not sit straight and flat in it's assembled form. This is a first for me.

Mike- I'm not sure how to post pictures on here but if you go to the Facebook page for JK and view the pictures of the chassis you'll see what I mean. The first picture (a recent picture) you come to shows a rear bite bar not parallel to the center section but tending to the left (like mine). The second picture of the chassis, which is an older picture shows a rear bite bar that is parallel to the center section. That chassis picture also seems to show bite bars with that small end nub turned down not flat like mine was, or it's an optical illusion, I wear glasses in my old age so my eyes may be playing tricks on me. This chassis has a 3 contact point design and the pan should sit flat IF that rear center hump is actually centered. If it isn't then there is a possibility that the pan will tend to one side. You would think it would tend to the heaver side of the pan which would be the bent end of the bite bar. The one thing I haven't done is to check to see if that hump is truly centered. If it isn't then that's most likely the problem.

#153

Posted 01 December 2016 - 11:22 AM

I have 6 of these chassis sitting on the bench . I am not ready to build them yet but I pulled them out to check them due to all the blah blah I am seeing on this post. They are all as flat or flatter than anything I have seen come out of a bag. I would say that they are of equal quality to the latest Patriots I have built, which is pretty darn good.

#154

Posted 01 December 2016 - 12:34 PM

This past Tuesday evening, one of my racing colleagues, Dan Parker, brought his new JK full dressed and ready to run during our weekly club gathering. He let me spend a few minutes on the controller and I found it handled incredibly well. It was able to take tight turns and banked turns nicely. I posted some good lap times in the short time I spent on the controller, then watched as Dan bested my times!

Looking forward to getting this chassis fully dressed and putting her to the test. Great work, JK!

South Carolina, USA

"Assuming either the Left Wing or the Right Wing gained control of the country, it would probably fly around in circles."

- Pat Paulsen, 1968

"I drive way too fast to worry about cholesterol."

- Steven Wright ca. 1983

#155

Posted 01 December 2016 - 01:13 PM

Also check that your pans are flat and touching your block right where the bite bar goes through. Mine took a lot of work to get the pans really evenly flat there.

Steve Meadows

#156

Posted 01 December 2016 - 02:54 PM

My intention here isn't to demean the chassis in any way. It is just to simply state the problem I'm having with mine. I have never had a chassis that once it was straight and flat would not sit straight and flat in it's assembled form. This is a first for me.

Mike- I'm not sure how to post pictures on here but if you go to the Facebook page for JK and view the pictures of the chassis you'll see what I mean. The first picture (a recent picture) you come to shows a rear bite bar not parallel to the center section but tending to the left (like mine). The second picture of the chassis, which is an older picture shows a rear bite bar that is parallel to the center section. That chassis picture also seems to show bite bars with that small end nub turned down not flat like mine was, or it's an optical illusion, I wear glasses in my old age so my eyes may be playing tricks on me. This chassis has a 3 contact point design and the pan should sit flat IF that rear center hump is actually centered. If it isn't then there is a possibility that the pan will tend to one side. You would think it would tend to the heaver side of the pan which would be the bent end of the bite bar. The one thing I haven't done is to check to see if that hump is truly centered. If it isn't then that's most likely the problem.

If you have a smartphone you keep pics on, posting pics to Slotblog is very easy.

I think I see what you're referring to on the JK website.

The couple chassis I have here don't have the rear bite sitting weird at all.

If you feel you may of gotten a defective chassis, you should take Tim up on his offer in post #111.

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#157

Posted 01 December 2016 - 03:32 PM

The second image has the chassis elevated at the front, and sitting on the very rear of the centre section. Possibly it's the same chassis? The pans are now hanging, which has pulled the JBar flat.

Steve Meadows

#158

Posted 02 December 2016 - 09:55 AM

- Lee Palmer likes this

Tim Homola

JK Products

#159

Posted 02 December 2016 - 11:51 AM

Sorry, I believe like Raymond Reddington (TV show "Blacklist"). I don't have a smartphone; I have a lowly flip phone.

Steve,

The first picture you show is how my chassis sat so I removed material from the top of the gear side tang on the pan and the chassis sits flat on the block. I have deburred the chassis completely, finding the front tangs on the pan to be especially challenging. Still no positive results but I'm not giving up. I replaced my broken J-bar with straight SS pin tubing and T-pins but it still tends to one side. I also changed the front J-bar, with the location of the J to the gear side from the non-gear side. There was a small change but still not right. I plan on some more filing with my mini square file on the front pan tangs as couple seem to be tighter then necessary and they certainly will not take a bigger diameter bar.

Tim,

I managed to get both the front and rear (before I broke it) bite bars perfectly flat; they were not the problem. If I figure out what's causing my grief I'll let you know, but I think it may have something to do with the alignment of those front tangs.

#160

Posted 02 December 2016 - 12:11 PM

Freddie,

It looks like you might have it ready in time for the "Surface Plate 500". LOL.

You'll have to excuse my sarcasm, but after driving Rob Voska's Cheetah A, which never had the pan removed from the center, .15 faster than any other similar car that had run on my technical flat track, I question if all the gymnastics you're doing with the pan is going to result in any performance gain.

- Racer36 likes this

Mike Swiss

Inventor of the Low CG guide flag 4/20/18

IRRA® Components Committee Chairman

Five-time USRA National Champion (two G7, one G27, two G7 Senior)

Two-time G7 World Champion (1988, 1990), eight G7 main appearances

Eight-time G7 King track single lap world record holder

17B West Ogden Ave., Westmont, IL 60559, (708) 203-8003, mikeswiss86@hotmail.com (also my PayPal address)

Note: Send all USPS packages and mail to: 692 Citadel Drive, Westmont, Illinois 60559

#161

Posted 02 December 2016 - 01:23 PM

Raced my first built "A" chassis last night. It's frighteningly fast. My best previous race was 283 vs last night a new record (for me) at 291. I was lucky and dodged lots of, though not all, of the collisions. Only a couple of minor self-inflicted wounds to report. What was fun was being able to confidently "press" and be aggressive when trying to make a clean pass.

And the single modification I made to the chassis, straight from the bag, was bending the guide tongue up a couple of degrees. I have to admit I never flipped it over so I don't have a clue how it looks inverted. (My observation is that when the car ends up inverted I'm often involved in issues far beyond worrying if the chassis is flat or aligned.) As previously reported, this chassis was so flat from the bag that I had trouble scraping it off of my granite surface plate when I checked it. This was likely due to the dynamic strength of molecular adhesion bonding I'm assuming.

Anyway, I am using a cut-down Koford guide with 25 thou of spacers and I don't think I can go lower looking at the black accumulation marks on the underside of the chassis. I will experiment this weekend with some body reinforcement under the bite-bars and maybe even some changes in bite-bar diameter if I can figure out how to make those cool bends that hold the bars in place.

As always, YMMV.

- MSwiss, SlowBeas, Les Boyd and 2 others like this

#162

Posted 02 December 2016 - 01:47 PM

Raced my first built "A" chassis last night. It's frighteningly fast. My best previous race was 283 vs last night a new record (for me) at 291...

What sort of track?

Steve Meadows

#163

Posted 02 December 2016 - 04:16 PM

Recently cleaned swoopy King. Flat track on the weekends.

#164

Posted 02 December 2016 - 04:17 PM

What's your times/laps on the flat track compared to X25?

Steve Meadows

#165

Posted 03 December 2016 - 11:25 AM

Since this chassis uses a specifically designed bite bar system and yes I know replacement bite bars will be available soon, would it still be a legal chassis with custom made bite bars, like Steve did in post 143, that may or may not closely resemble the manufactures design? Since the other chassis that use bite bars only use straight wire or pin tubing and racers are more or less free to make their own.

By the way, hey, Steve, what kind of a wire bender did you use to make those custom bite bars?

#166

Posted 03 December 2016 - 01:59 PM

FF: Legality will depend on your own clubs rules

This is my bender I use. It only does one radius, unlike the factory bent bars

Steve Meadows

#167

Posted 04 December 2016 - 05:00 AM

Finally I have it running properly with little to no tyre coning.

Solid race car now.

Steve Meadows

#168

Posted 04 December 2016 - 06:18 AM

- Frankie Schaffier likes this

#169

Posted 04 December 2016 - 07:21 AM

Can you slide paper under that thing?

Is that legal anywhere?

- olescratch likes this

#170

Posted 04 December 2016 - 09:11 AM

Frankie

Professional Track Wall Tester.

Rob Voska's only friend.

#171

Posted 04 December 2016 - 09:57 AM

FYI To make tech here (depending on club) we have to start with either .5mm or .6mm clearance.

Steve Meadows

#172

Posted 04 December 2016 - 11:05 AM

#173

Posted 06 December 2016 - 05:13 AM

I see the whole range of comments here. Graeme Stephenson and I did the pre-release tesing on this chassis at Raceway 81 in the UK (you probably saw the videos on Facebook).

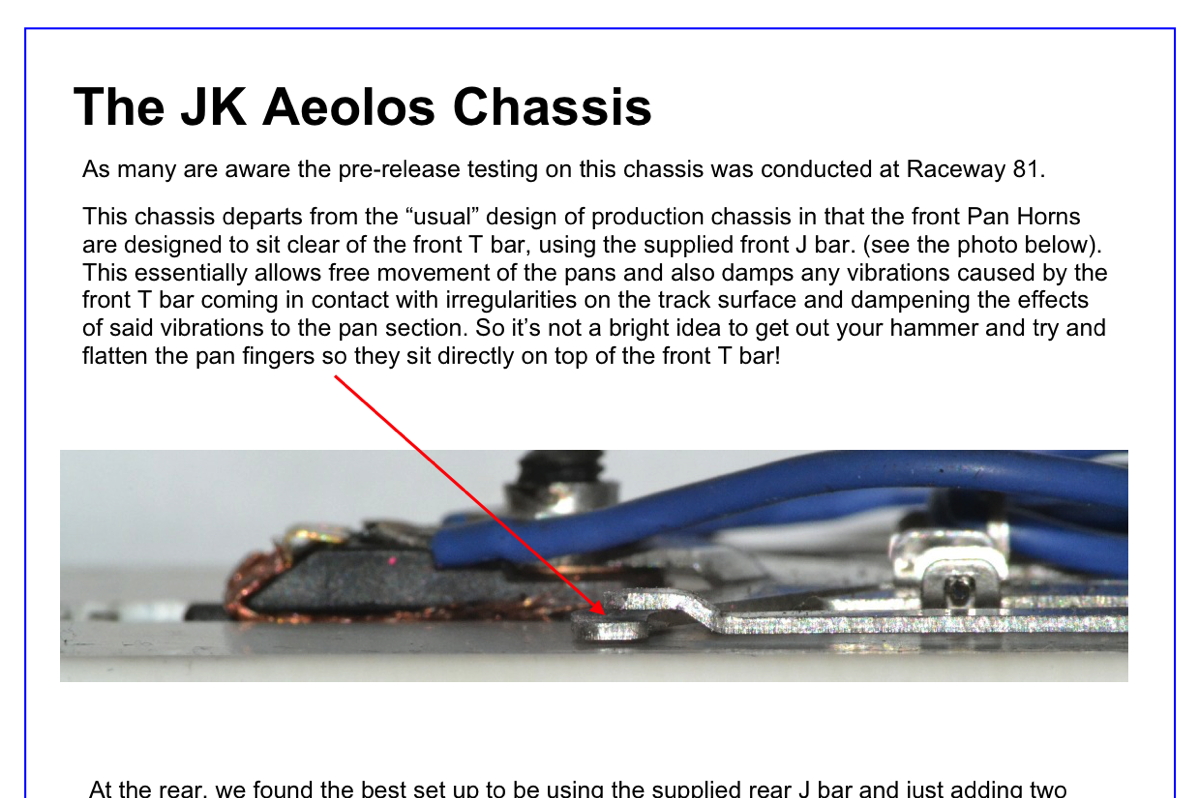

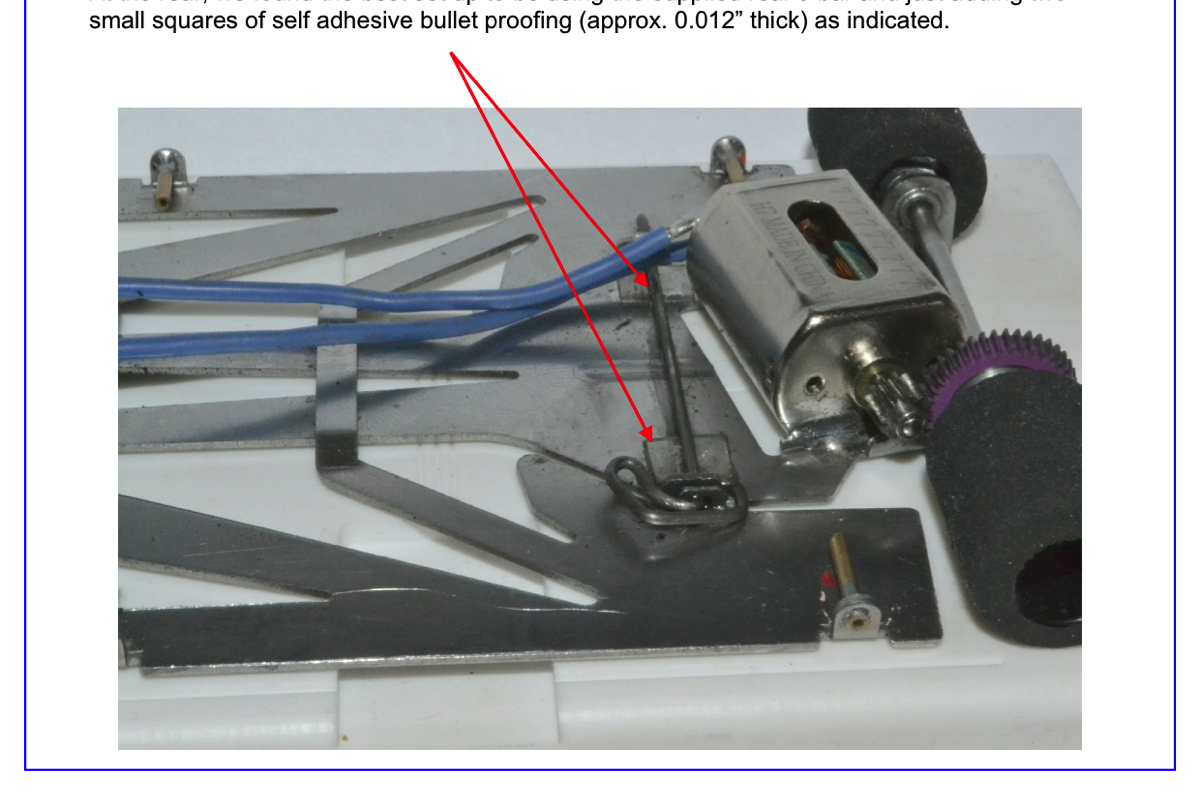

Racers should realise that this chassis was designed primarily for "ISRA" type racing, which means that it is lighter and tougher than the previous X25 chassis. Not only that but it is essentially a pretty revolutionary design for a pressed chassis. This means a number of things.

1) It is light and primarily will work far better with thinner, lighter bodies (such as the present ISRA saloon body from Attan - The Mercedes) or any 7 thou LMP or G12 type sports body (BPA Lola or the JK range of LMPS).

2) The pans on this chassis are designed to "float" on the J bars, not to sit flat on the center section like traditional pressed chassis. So you will see clearance between the pan fingers and the front T bar and also between the center section and the pan cross bar. The J bars, although thinnish piano wire, are only in "shear" (where they join both section together), so bending or snapping these is almost impossible. I lent the test car to my 12-year old grandaughter and she smashed it into every barrier, wall, and floor in an 18 minute segmented race and it came out of that as good as it started.

The reason the pans "float" on the Jbars is not only to ensure smooth movement, but also to isolate/deaden any vibrations from the centre section, caused by variations in the track surface.

The one thing we did notice is that unlike most other pressed chassis it is not necessary to "nail" the front T bar on the track to make it handle and just a couple of thou front clearance works well, so the T bar only picks up crud on the outside tips. This is especially important in FK racing as it reduces rolling resistance and increases straigt line speed due to less drag.

The testing was done with both a Hawk 7 and a Pro Slot G12 (obviously in different runs). The track lap record was smashed with the G12 motor within a short time (the previous lap record on the track being set by James Cleave, UK national Champion, at last year's British Open Championship race). Gear ratio 7/40.

The attached is a short report on the chassis set up. I hope this is of interest. You can also download a PDF version of this document at www.abslotsport.biz (under the order section for this chassis on the Quick Buy page)

- Pablo, Frankie Schaffier, Samiam and 2 others like this

#174

Posted 06 December 2016 - 09:31 AM

And this chassis is the best thing since sliced bread.

It is a "dream drive" for beginners and old hands alike.

#175

Posted 06 December 2016 - 06:32 PM

Steve Meadows