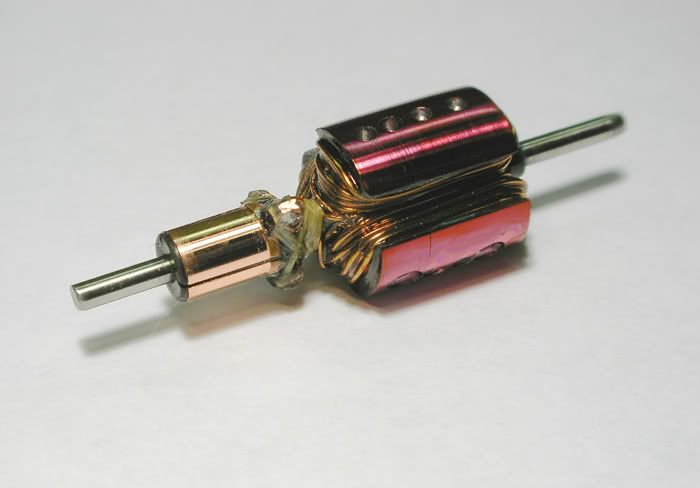

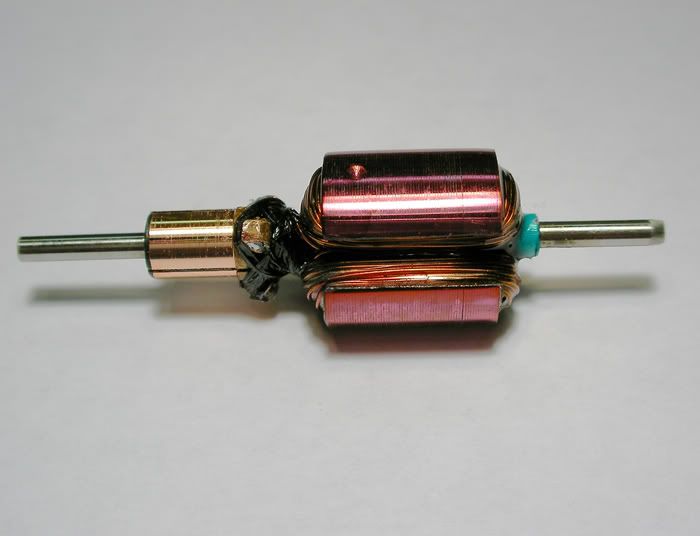

Having been 'Bitten' by the whole Retro thing,..I Managed to 'Dig Up' a Whole Heap of My Real OLD Slot Car stuff,..and Lo and Behold,..I have Found My Very First,..

'Hand Wound',.."Proper" Race Arm,..that I spoke of in a Previous Post.

This was actually, a Great Arm and is One that,..considering it was My First serious attempt,..Waaaay Back when I guess I was Onl;y about 14 or 15, Ain't too Bad!

The Fact that it Ran Extremely Well,..(Especially for a Statically Balanced arm!!),..to the Point where I even 'Re Balanced it some years Later and Won another Race with it !!

It was,..Just 'One of those Arms',..You Know?,..the ones that Just Run 'Right' and Never Get too Hot !!,..

It's a 20 of 25, wound with MURA Wire, Held together with MURA 'Team Cukras Epoxy' !!

At the time, one of the Local Pro's,..(Steve Hutcheson), helped and gave me advice on Winding and actually 'Assisted' in MY Static Balance of the Arm at His Place, using His Balance Edge set up that He had Made and was Excellent.

When I First Started Racing,..'Hutcho' as he was known, wound Amazing Motors!,..Quite Often Long Stacks as that was The Norm in That era, with the weight of the Cars and with Our Tracks/Power etc , he even made his own Comm welder and was one of the Few who you would let True the Comm for you,..almost Unheard of waay back by the average racer,..lol

Oh what Memories opening Up THAT Box of Old slot car bits has brought back !!,..

Stoo

This topic is locked

This topic is locked