Hi Kim,

Thanks for looking-in buddy

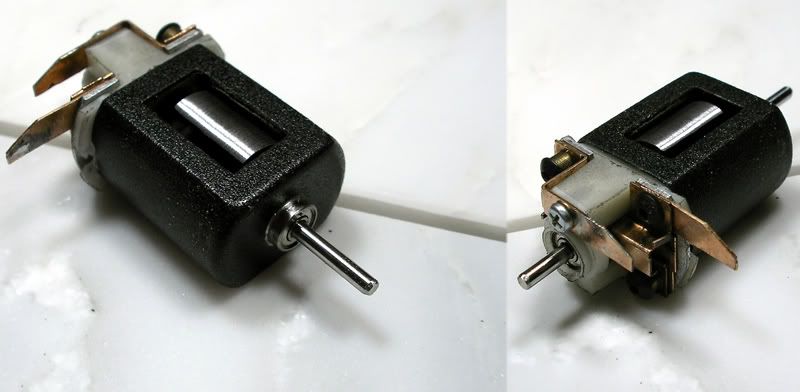

I think that this kind of motor with these magnets will be about maxxed-out with a #25 or a #26 wind. When I've done them based on a Mura C can with ceramic magnets, the #26 seems to work really well. These neos seem about 10% stronger than those magnets so I wanted to try the #23 and I think it's past the useable point...but surprisingly not by a whole lot. Being able to build these things and try stuff out makes it relatively easy to experiment with different winds and not "break the bank" money-wise, so I'm going to do a #25 for this motor now and that should be the final arm that "lives" in this thing. Your #26 Walnut is (to me) a great package, small and high-reving to make up for not having the brute torque of say those gorgeous golden-era Muras you see in some of Rick T's builds. These are much more like the awesome stuff that Dennis has shown in 1/32 where a smoother power-band and driveability are key. They seem similar to what Bill Bugenis has described to me as what the eurosport racers use...but in a

Flintstones lo-tech version.

On the shunt connectors, I actually have looked around for some really small solderless "spade" or "ring" terminals to use for shunts as it would seem much better than soldering them on, I never found any the right size (they'd need to be really small to be useful). I'd love to try some; not only would it make for a neater installation...but probably easier as well. Thanks again Kim

Hi Gus,

I'm not familiar with Paul's work, but he sounds like a real gonzo-engineer type...my kinda guy! I'm sure that he was probably waaaaaay past what I'm doing though because those days there were actual racing programs for this stuff. Home-wound arms would have a very tough time keeping up with the beautiful factory stuff produced today. I suppose that sending the arms out for dynamic balancing would add a bit more tto the performance thing, but then they wouldn't be "all-mine". Doing all this as a kid in the 60's, I didn't have a clue as to why some arms ran well and others vaporized or worse...detonated. Now I at least have a clue and the further along I go, the less problems I have and the more I want to experiment. Thanks for looking-in Gus!

-john

This topic is locked

This topic is locked