On sale five years ago , I also acquired one of Sherline's programmable CNC-controlled rotary tables and a right-angle attachment to mount the rotary table horizontally onto the milling machine's X-Y table, so that the workpiece rotates under CNC control below the vertical headstock's gear cutter.

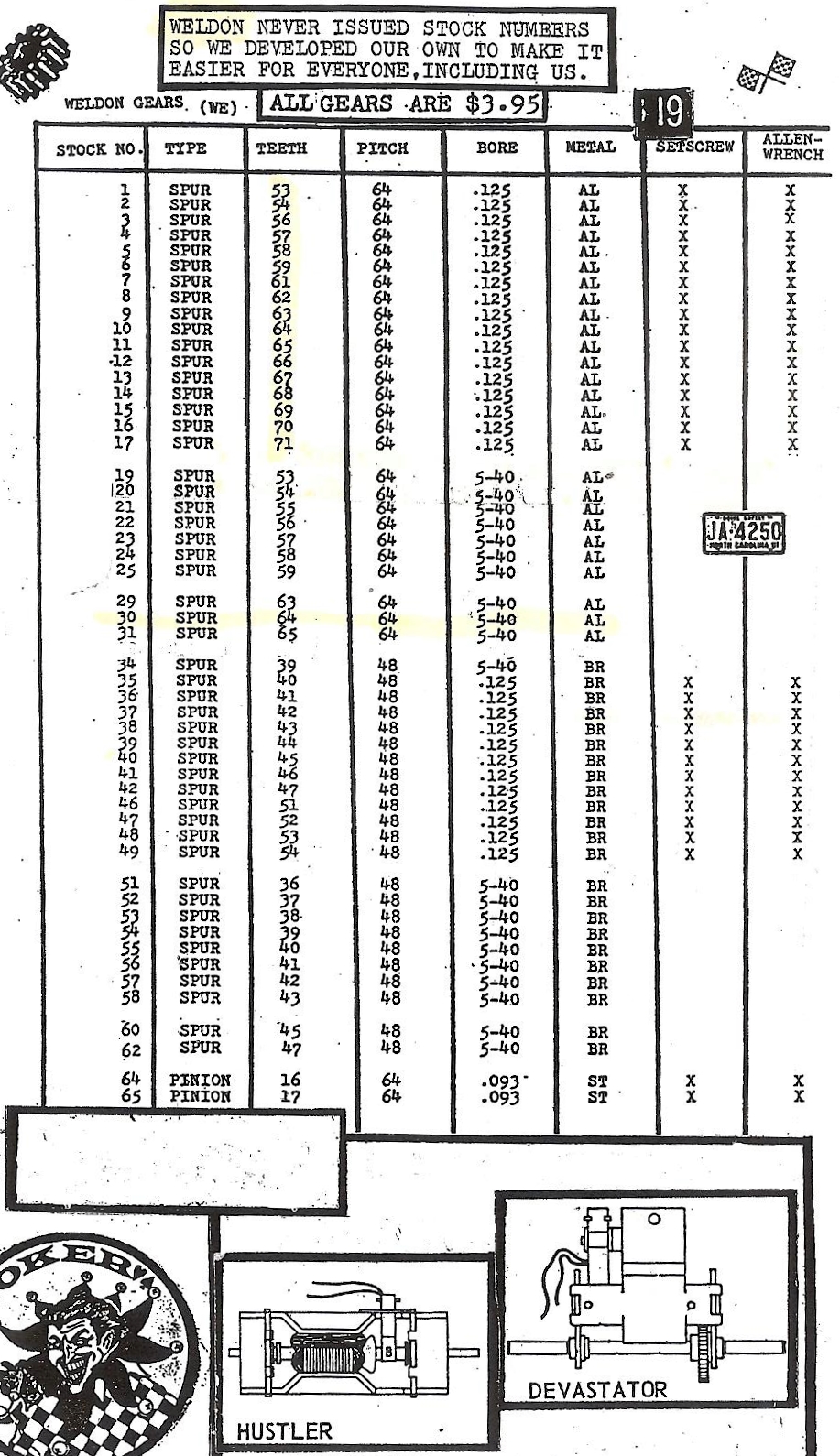

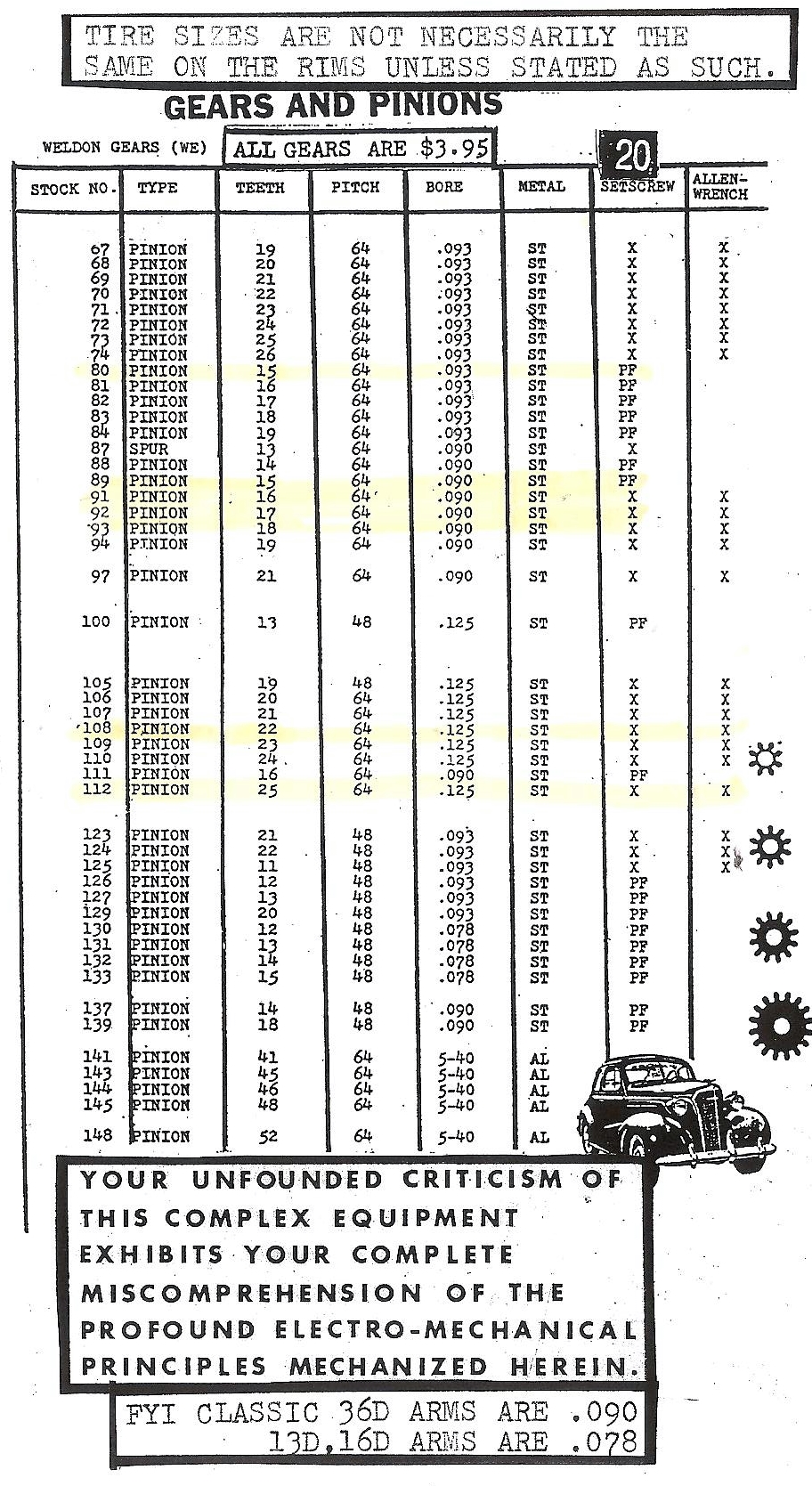

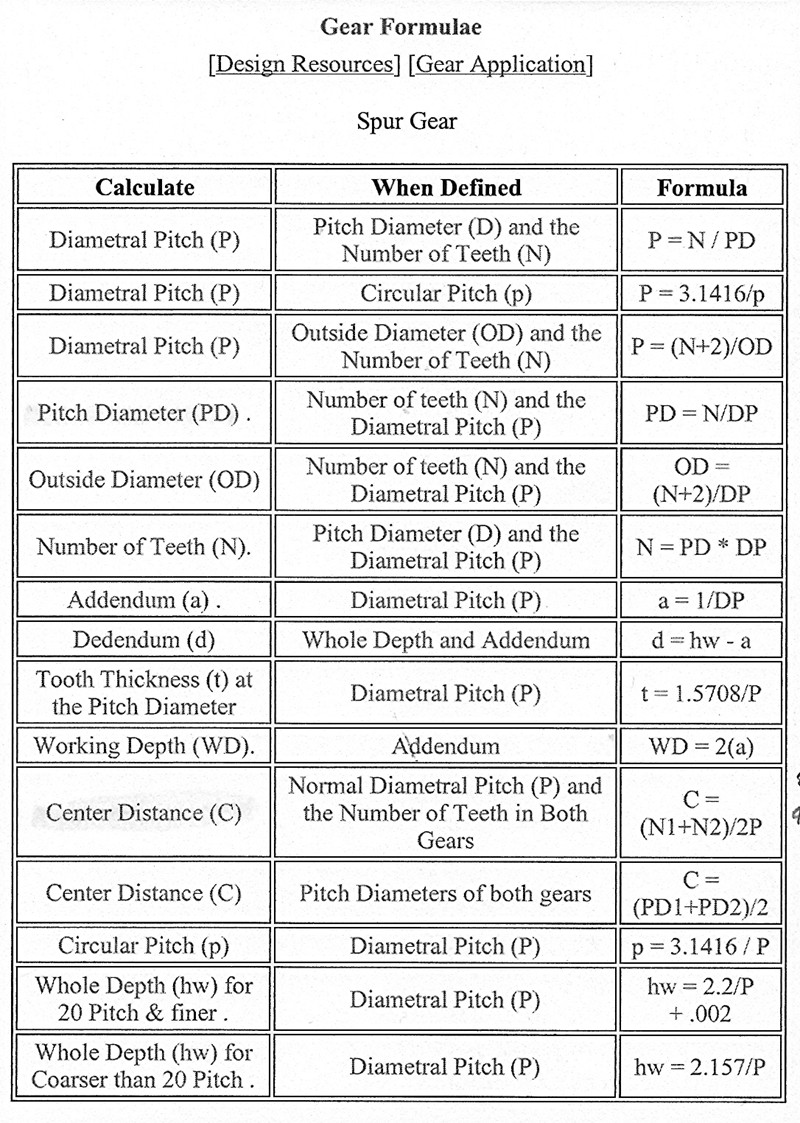

What stopped me in my tracks from pursuing this any further was the fact that I couldn't find a full set of involute gear-cutting tools needed to cut 64 pitch spur gears for an affordable price seven or eight years ago.

Yesterday, I went online and found a complete set of eight 64 pitch, 20 degree pressure angle, involute gear cutters for a reasonable cost. I ordered a set which should arrive later this week or next.

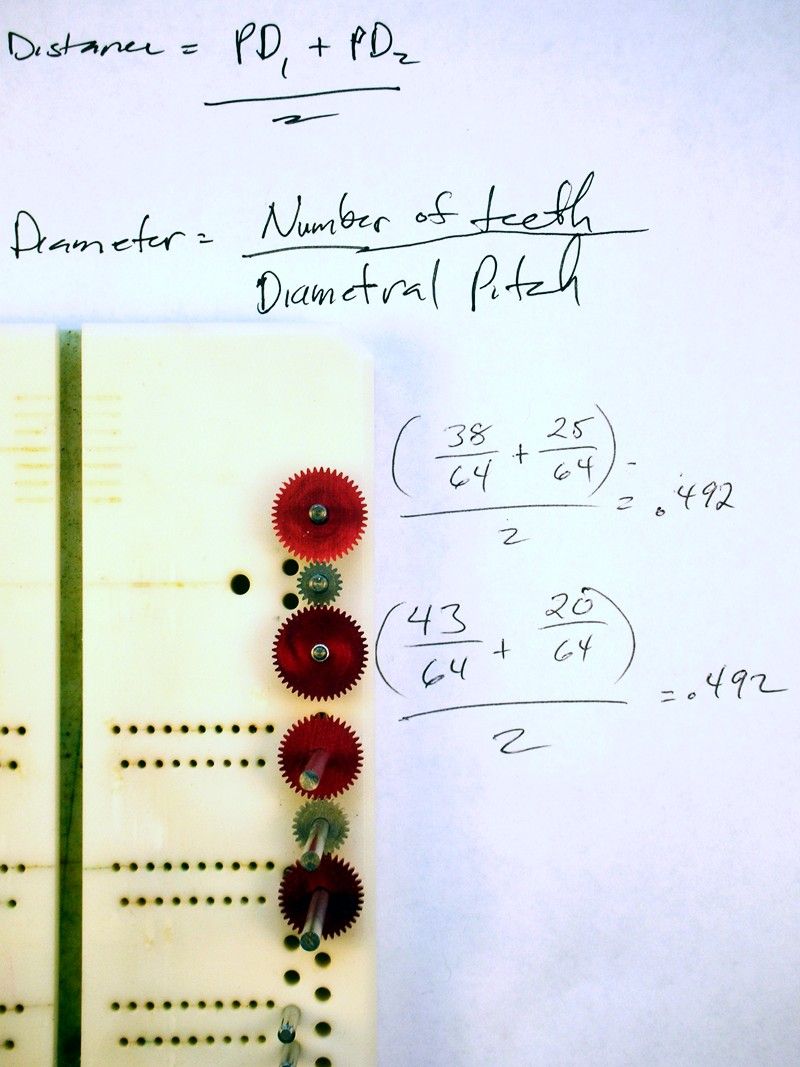

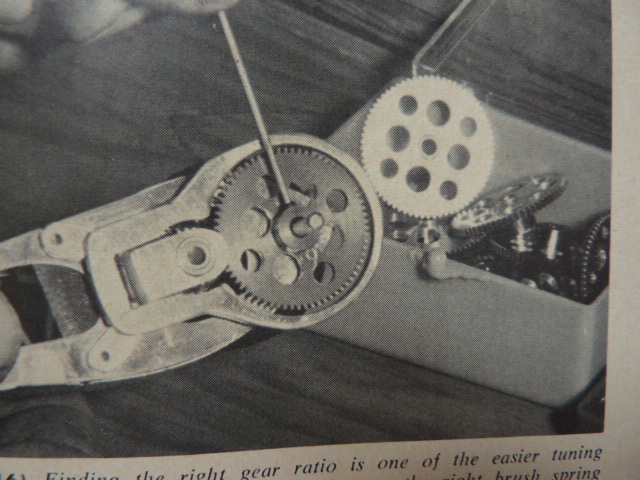

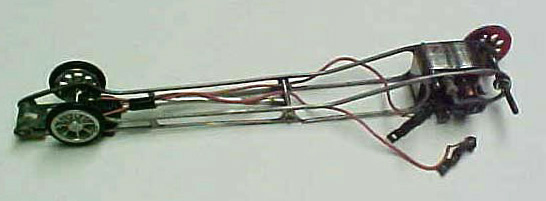

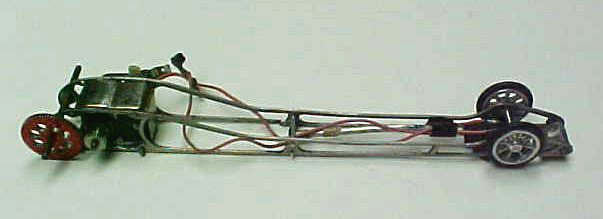

Now I will be able to fabricate the aluminum axle spur gears I need to fill the "gaps" in the 70T - 66T series required to build and race replicas of Gene Husting's and Manual Maldonado's dragsters.

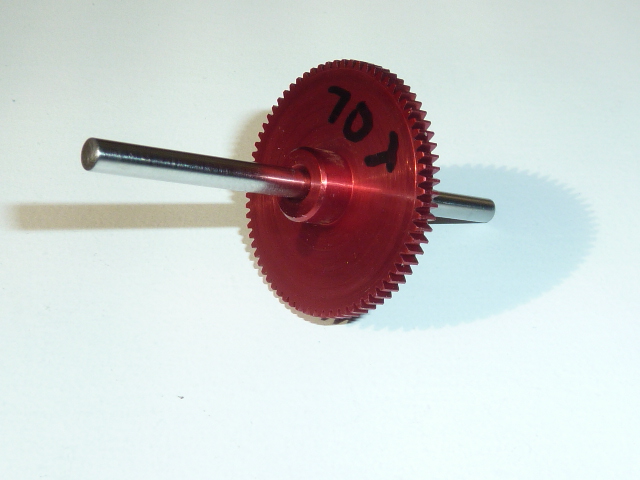

Naturally, the fewer aluminum spur gears I need to fabricate the better. So, I don't need to fabricate 70T gears because I already have two of them, one for each dragster.

If I obatin one 69T Weldun gear from Rick T. and can't find any others, I'll have to make another one myself for the second car.

The same holds true for the single 68T Weldun gear available from Don S.: I'll need to fabricate a duplicate 68T gear. No 67T Weldun gears have turned up yet, so I will need to fabricate two of them.

I don't have any Weldun 26T steel pinions to pair with the 66T gears I have, but that's where my gear-fabrication ambitions end. There's no way I'm going to try replicating Weldun's steel pinion gears!

Well, I've pretty much thrashed this subject to death...

![]()